Oral medicine practice model formed through encapsulation injection molding and method thereof

A technology of injection molding and encapsulation, which is applied to teaching models, educational tools, instruments, etc., can solve problems such as labor-intensive, poor glue bonding, and environmental protection, and achieve low production efficiency, less flash, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

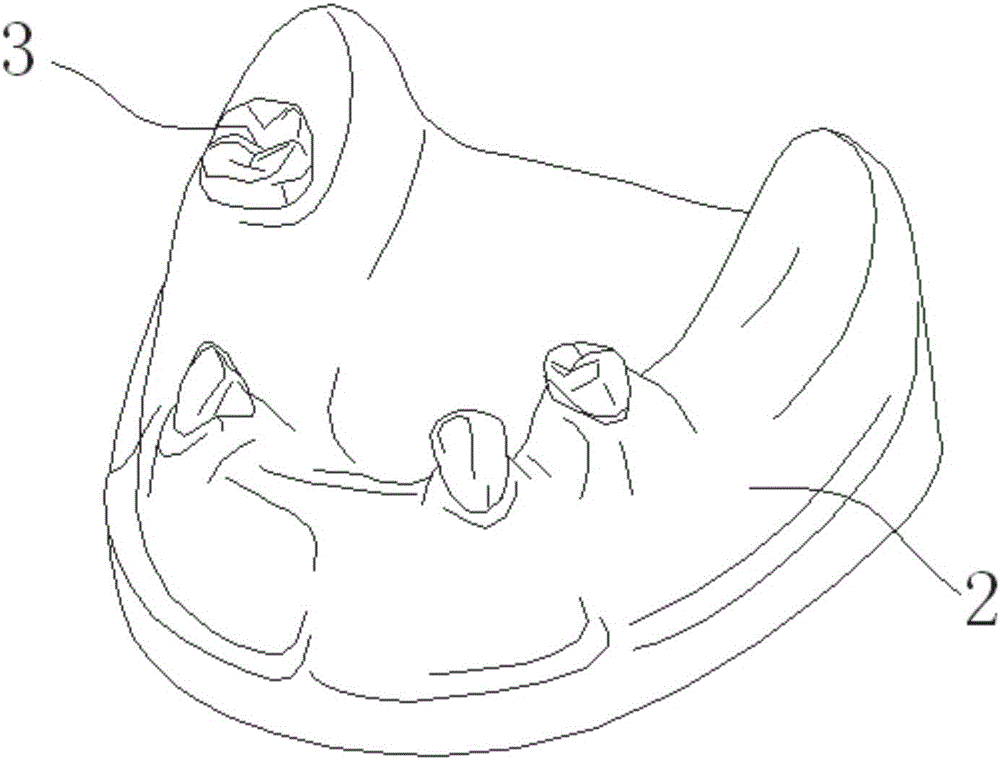

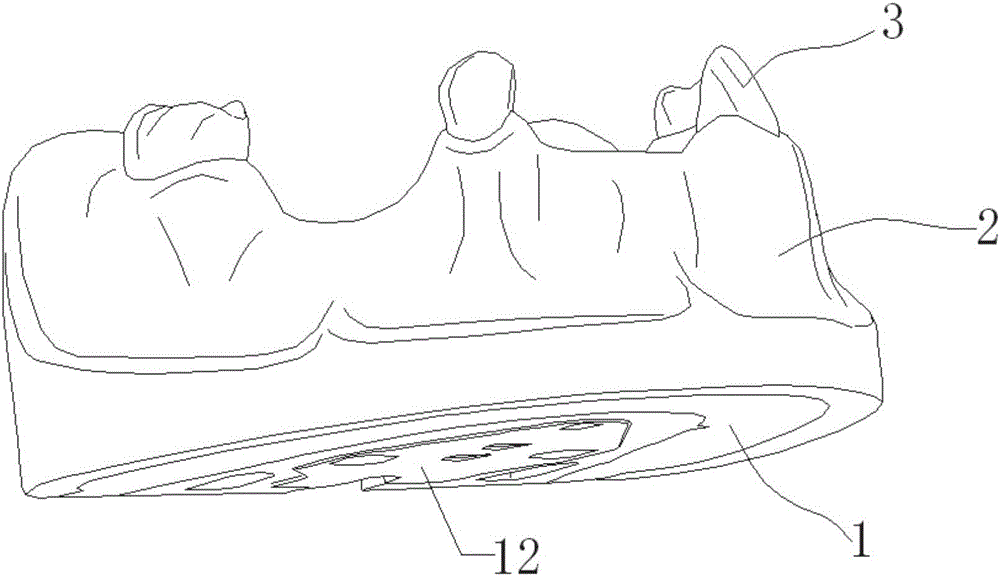

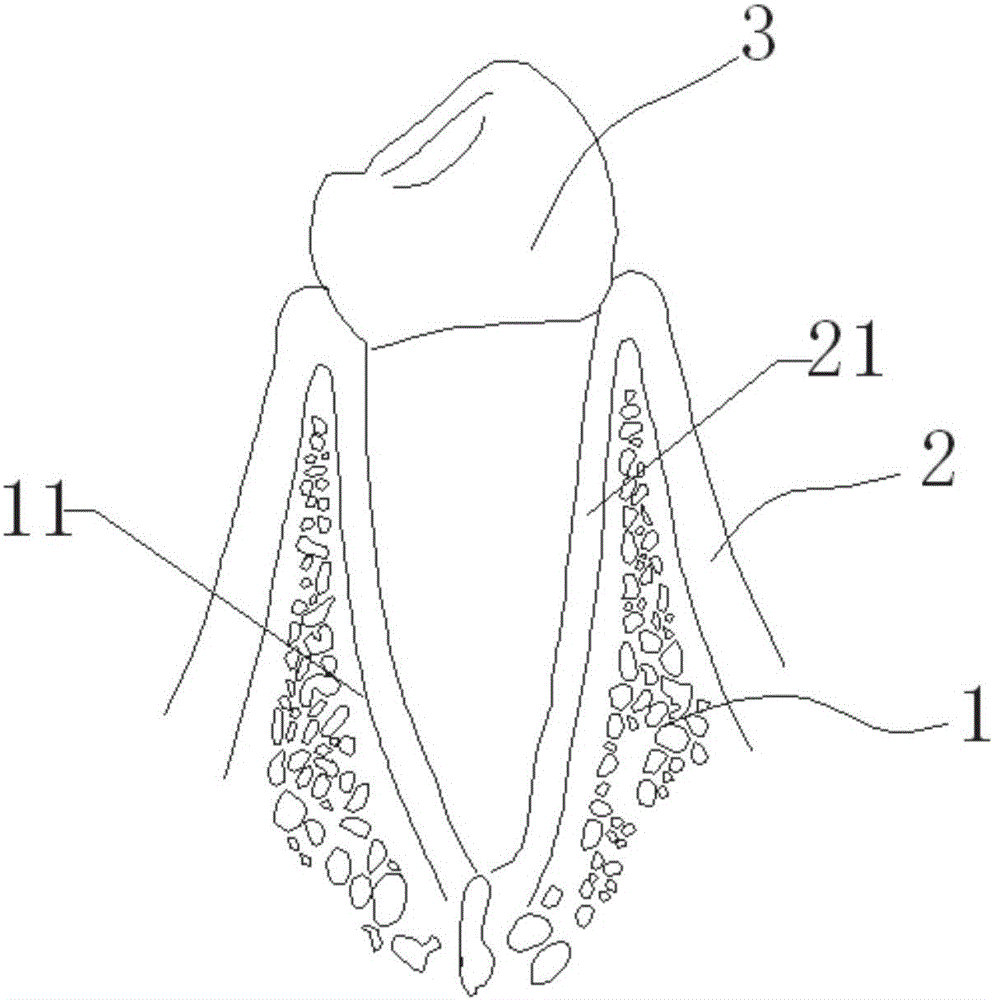

[0036] Such as figure 1 , figure 2 and image 3 As shown, a plastic-coated injection-molded oral practice model includes an injection-molded alveolar bone 1, the top surface of the alveolar bone is formed with several alveolar sockets 11 according to the needs of the practice, and the bottom surface of the alveolar bone is formed with Fixed to the cavity of the rubber-coated mold and the positioning connection structure 12 on the imitation head mold, the surrounding side of the alveolar bone is formed with a rubber-coated groove 13 near the bottom surface, and the rubber-coated groove can make the soft tissue and the alveolar bone injection molded and combined More tightly, the top surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com