Anti-explosion temperature controller

A thermostat and housing technology, which is applied in the field of explosion-proof thermostats, can solve the problems of complicated structure, poor sealing effect, poor use effect, etc., and achieve a wide range of temperature control and adjustment, small temperature difference between start and stop, and large overload current Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

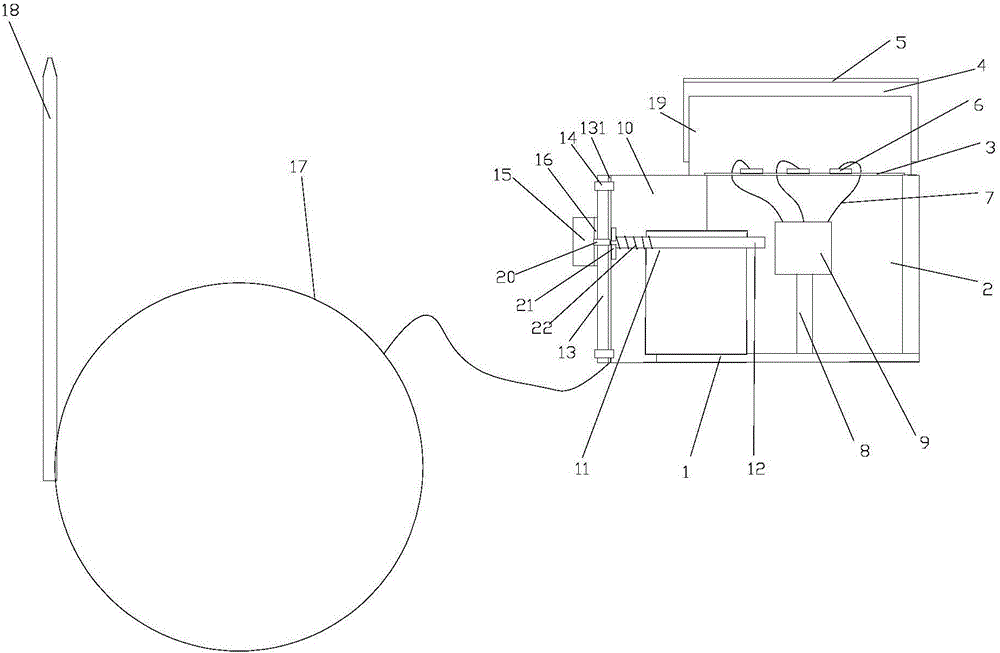

[0014] Such as figure 1 The explosion-proof thermostat shown in our company is E507S-LS, which includes a base 1, a housing 2 is arranged on the base 1, a screw column 19 is connected to the top of the housing 2, and the top of the screw column 19 is connected with a top Cover 4, a sealing ring 5 is installed in the top cover 4, the left end of the housing 2 is connected with a cover plate 13 through a nut 14, a rectangular sealing ring 131 is installed between the cover plate 13 and the housing 2, and the left side of the cover plate 13 is connected with a Knob cover 15, a knob (not shown in the figure) is installed in the knob cover 15, a bolt 20 is connected to the side end of the knob, a gasket 16 is installed between the cover plate 13 and the knob cover 15, and a cavity 10 is arranged in the housing 2, The middle end of the cavity 10 close to the cover plate 13 is provided with a metal induction sheet 21, the middle end of the metal induction sheet 21 is connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com