Silica activated carbon composite material, its preparation method and lead-carbon battery

A technology of composite materials and silicon dioxide, applied in the direction of lead-acid batteries, battery electrodes, circuits, etc., can solve the problems of cycle life and high current charge and discharge acceptance ability, weak fast charge acceptance ability, and poor low temperature charge and discharge ability To achieve the effect of improving the ability to accept high-current charge and discharge, inhibiting irreversible sulfation, and improving the distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

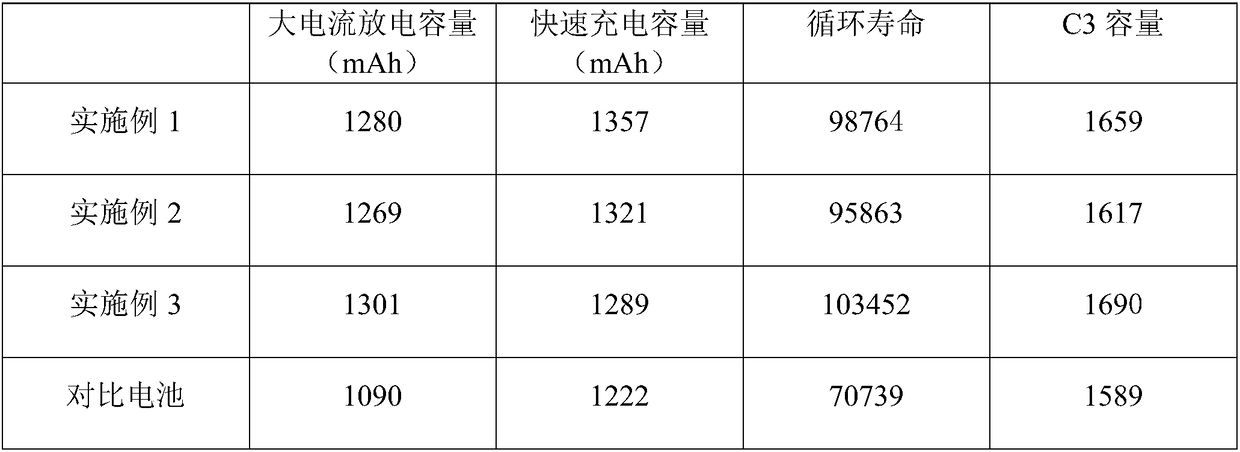

Examples

Embodiment 1

[0040] The method for comprehensively recycling rice husk and its derivatives and preparing porous ultrafine silica activated carbon composite materials for lead-carbon batteries comprises the following steps:

[0041] 1) Soak the rice husk in sulfuric acid solution for 24 hours, the concentration of sulfuric acid is 1mol / L, filter and wash to obtain purified rice husk;

[0042] 2) Put the purified rice husks into a tube furnace, and undergo drying, carbonization and primary activation treatment to obtain carbonized rice husks;

[0043] The heating system is divided into three temperature control stages:

[0044] Heating stage 1, heating rate 3°C / min, to 100°C, keep warm for 20min;

[0045] Heating stage 2, N 2 , the carrier gas flow rate is 5L / min, the heating rate is 6°C / min, and the temperature is kept at 600°C for 100min;

[0046] In heating stage 3, water vapor is introduced, the carrier gas flow rate is 5L / min, the heating rate is 6°C / min, and the temperature is reach...

Embodiment 2

[0052] The method for comprehensively recycling rice husk and its derivatives and preparing porous ultrafine silica activated carbon composite materials for lead-carbon batteries comprises the following steps:

[0053] 1) Soak the rice husk in sulfuric acid solution for 36 hours, the concentration of sulfuric acid is 0.85mol / L, filter and wash to obtain purified rice husk;

[0054] 2) Put the purified rice husks into a tube furnace, and undergo drying, carbonization and primary activation treatment to obtain carbonized rice husks;

[0055] The heating system is divided into three temperature control stages:

[0056] Heating stage 1, heating rate 2.5°C / min, to 95°C, keep warm for 30min;

[0057] Heating stage 2, N 2 , the carrier gas flow rate is 4L / min, the heating rate is 5°C / min, to 550°C, hold for 120min;

[0058] Heating stage 3, CO2 2 , the carrier gas flow rate is 4L / min, the heating rate is 5°C / min, to 750°C, keep warm for 80min, then stop heating, and continue to p...

Embodiment 3

[0063] The method for comprehensively recycling rice husk and its derivatives and preparing porous ultrafine silica activated carbon composite materials for lead-carbon batteries comprises the following steps:

[0064] 1) Soak the rice husk in hydrochloric acid solution for 12 hours, the concentration of hydrochloric acid is 1.25mol / L, filter and wash to obtain purified rice husk;

[0065] 2) Put the purified rice husks into a tube furnace, and undergo drying, carbonization and primary activation treatment to obtain carbonized rice husks;

[0066] The heating system is divided into three temperature control stages:

[0067] Heating stage 1, heating rate 3.5°C / min, to 105°C, keep warm for 15min;

[0068] Heating stage 2, N 2 , the carrier gas flow rate is 6L / min, the heating rate is 8°C / min, and the temperature is kept at 650°C for 90min;

[0069] In heating stage 3, water vapor is introduced, the carrier gas flow rate is 6L / min, the heating rate is 8°C / min, to 850°C, keep w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com