Multilayer printed circuit board drilling method

A printed circuit board, multi-layer printing technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of destroying signal integrity, low efficiency, high price of blind hole or buried hole process, and avoid process price High, reduce length, avoid the effect of inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

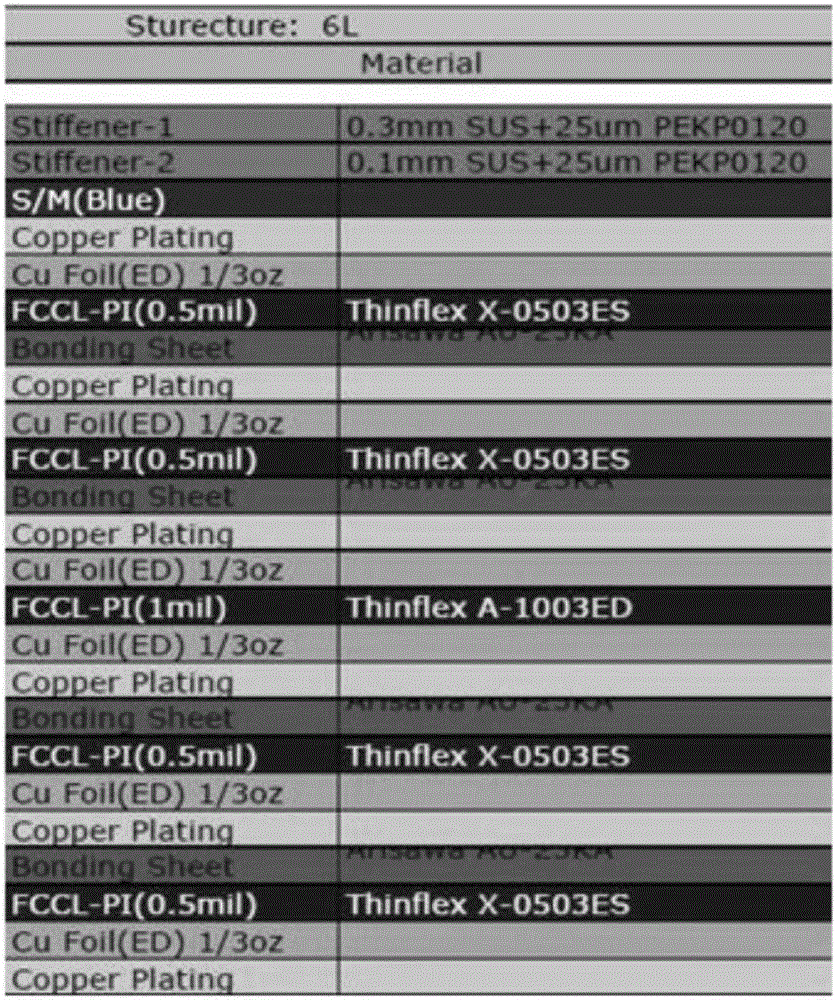

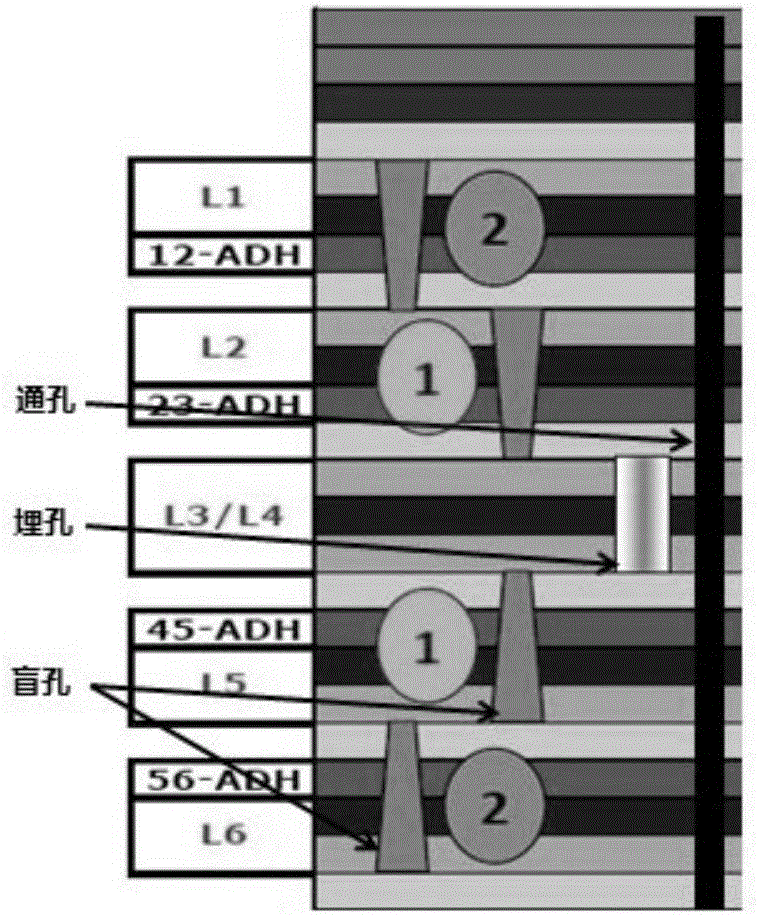

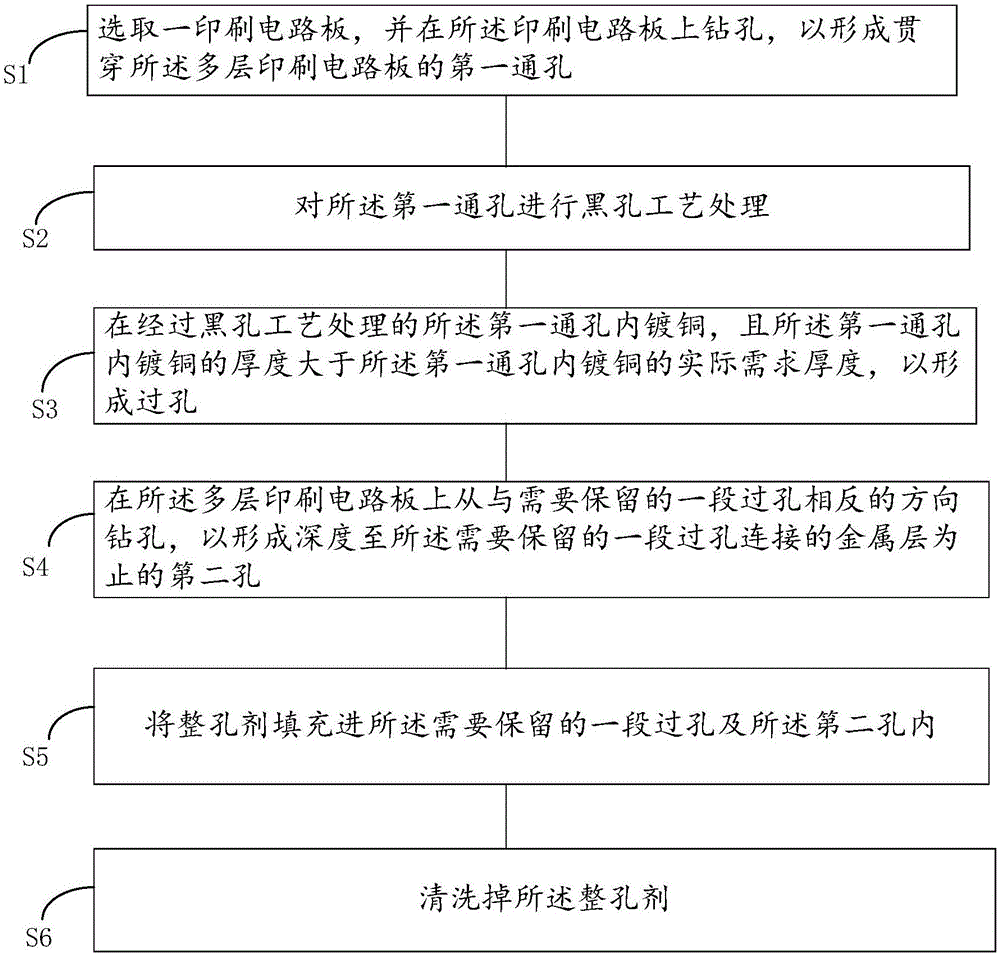

[0033] see image 3 and Figure 4 , is the flow chart and process flow chart of the first embodiment of the multilayer printed circuit board drilling method of the present invention. In this embodiment, the multilayer printed circuit board is a flexible printed circuit board, and the flexible printed circuit board is a high Reliable and flexible printed circuit, referred to as soft board, has the characteristics of high wiring density, light weight, and thin thickness. It is mainly used in mobile phones, notebook computers, PDAs, digital cameras, LCM and other products. And in this embodiment, the flexible printed circuit board is a 4-layer printed circuit board, which includes first to fourth metal layers 11 - 14 and an insulating layer 15 spaced between every two metal layers.

[0034] The multilayer printed circuit board drilling method includes:

[0035] Step S1: Select a printed circuit board, and drill holes on the printed circuit board to form a first through hole pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com