Artificial graphite flake and manufacturing method thereof, and graphite substrate stack structure containing artificial graphite flake

A technology of artificial graphite sheet and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that the heat dissipation substrate cannot effectively meet the thermal diffusion and heat conduction, the life of high-power LEDs is limited, and it is difficult to use long-term and normal. Achieve the effects of improving production yield and flatness, reducing easy cracking, and increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

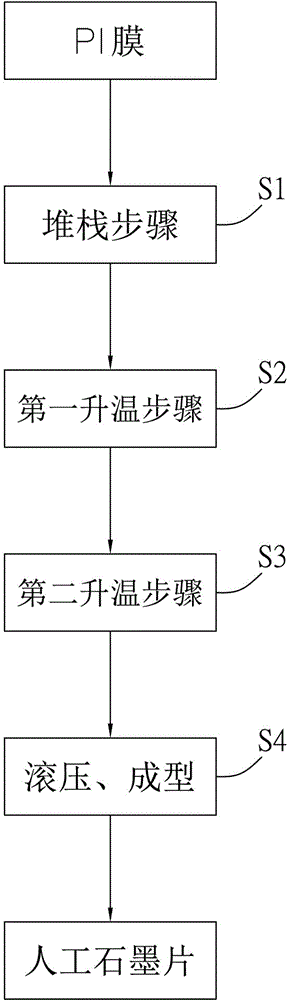

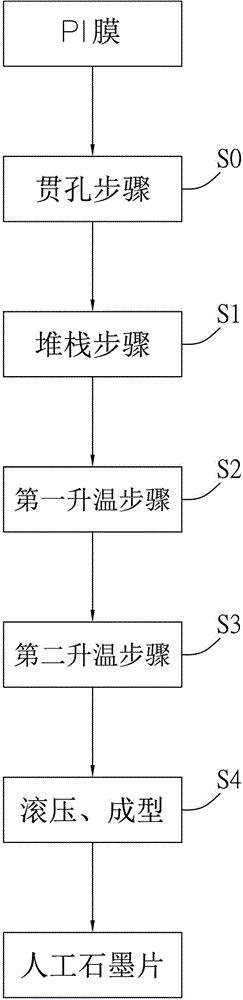

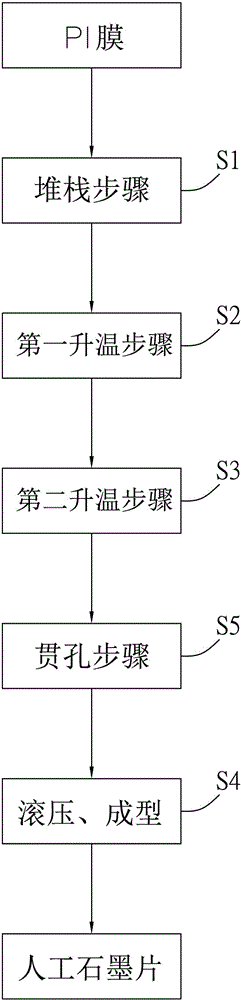

[0043] see figure 1 , it can be seen that the main process of the manufacturing method of the artificial graphite sheet in the embodiment of the present invention includes stacking step S1, the first heating step S2, the second heating step S3 and rolling, forming S4 and other processes; of course, before stacking, it will be selected first. The predetermined material PI film (polyimide film) is cut into a preset size specification, and then enters the stacking step S1, wherein the thickness of the material PI film used above is preferably between 10-200um.

[0044] Stacking step S1, which is mainly to cross-stack the PI film and natural graphite dust paper, so that each PI film is between two natural graphite dust papers; for the state of stacking, please refer to Figure 4 , which is to stack the PI film 20' and the natural graphite dust paper 12 to a preset number of layers or height, separate them with at least two graphite plates 11 and press them on and below them, and p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap