Eco-friendly mineral wool board and preparation method thereof

A mineral wool board, an environmentally friendly technology, applied in the field of environmentally friendly mineral wool board and its preparation, can solve the problems of easy loss of starch and attapulgite clay, increased use of binders, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

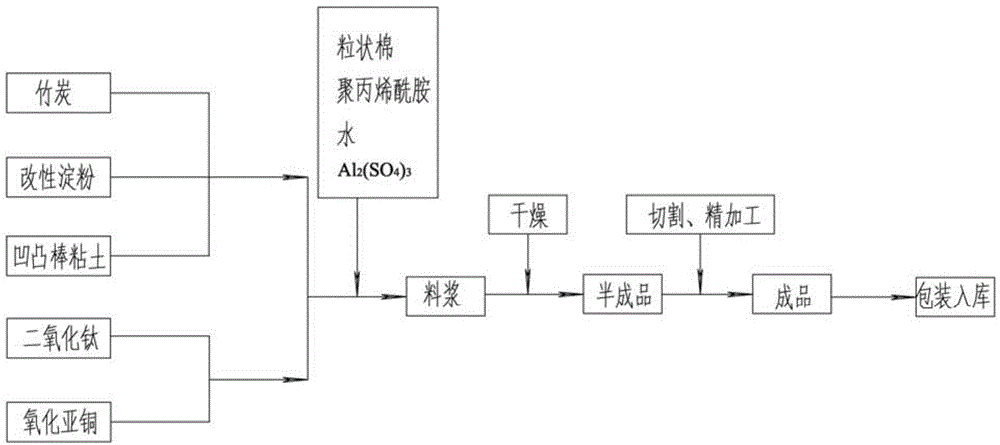

[0022] according to figure 1 The flow chart shown is for the preparation of environmentally friendly mineral wool boards.

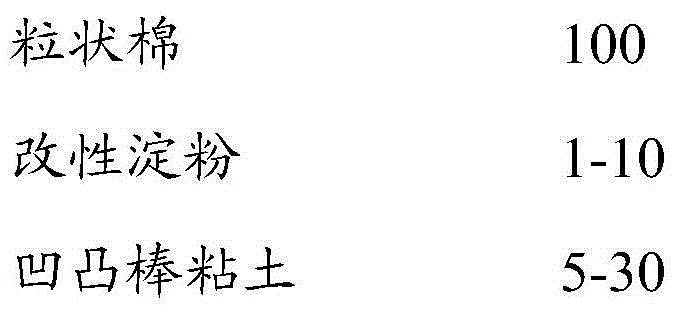

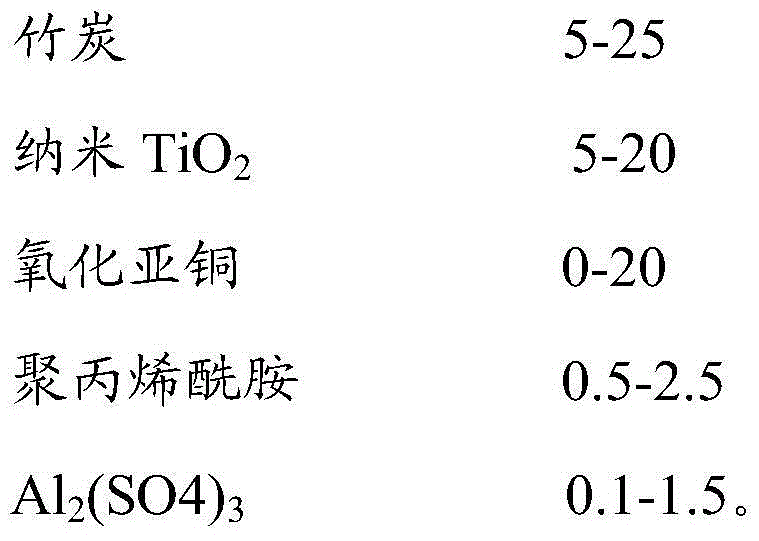

[0023] Step 1: weigh 5 parts by weight of modified starch, 20 parts by weight of attapulgite clay, and 10 parts by weight of bamboo charcoal, and stir evenly;

[0024] Step 2: Weigh Nano TiO 2 15 parts by weight, 10 parts by weight of cuprous oxide, stirred evenly;

[0025] Step 3: Weigh 100 parts by weight of granular cotton, 1.0 parts by weight of polyacrylamide, Al 2 (SO 4 ) 3 0.5 parts by weight, stirred with the two homogeneous mixtures obtained in steps 1 and 2 for 4 minutes until uniform;

[0026] Step 4: Stir the solid homogeneous mixture in step 3 with water evenly, and adjust the solid content of the mixed slurry to be 4%;

[0027] Step 5: The above-mentioned mixed slurry is taken into shape by wet method, and cut into large boards;

[0028] Step 6: Transport the above-mentioned slabs to a drying kiln, and dry them at 260° C. for 1.5 hour...

Embodiment 2

[0031] The difference from Example 1 is that the addition amount of each raw material component and the temperature and time of drying are different, and the addition amount and drying temperature are as follows respectively:

[0032] 100 parts by weight of granular cotton;

[0033] 10 parts by weight of modified starch;

[0034] Attapulgite clay 30 parts by weight;

[0035] 25 parts by weight of bamboo charcoal;

[0036] Nano-TiO 2 20 parts by weight;

[0037] 20 parts by weight of cuprous oxide;

[0038] 2.5 parts by weight of polyacrylamide;

[0039] Al 2 (SO4) 3 1.5 parts by weight;

[0040] Dry the plate at 285°C for 1 hour;

[0041] Tests have shown that the environmentally friendly mineral wool board of this embodiment, compared with the traditional mineral wool board, has a formaldehyde removal rate of more than 90% after being irradiated by fluorescent lamps for 24 hours; the loss of binder is reduced, and the loss is reduced by 65% compared with the tradit...

Embodiment 3

[0043] The difference from Example 1 is that the addition amount of each raw material component and the temperature and time of drying are different, and the addition amount and drying temperature are as follows respectively:

[0044] 100 parts by weight of granular cotton;

[0045] 1 part by weight of modified starch;

[0046] 5 parts by weight of attapulgite clay;

[0047] 5 parts by weight of bamboo charcoal;

[0048] Nano-TiO 2 5 parts by weight;

[0049] 0.5 parts by weight of polyacrylamide;

[0050] Al 2 (SO4) 3 0.1 parts by weight;

[0051] Dry the plate at 230°C for 2 hours;

[0052] Tests have shown that the environmentally friendly mineral wool board of this embodiment, compared with the traditional mineral wool board, has a formaldehyde removal rate of more than 70% after being irradiated by fluorescent lamps for 24 hours; the loss of binder is reduced, and the loss is reduced by 25% compared with the traditional process .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com