Method for improving petroleum wax smell and appearance

A petroleum wax and smell technology, which is applied in the refining of petroleum wax, etc., can solve the problems of unqualified petroleum wax smell, bulging of wax plate, color change and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

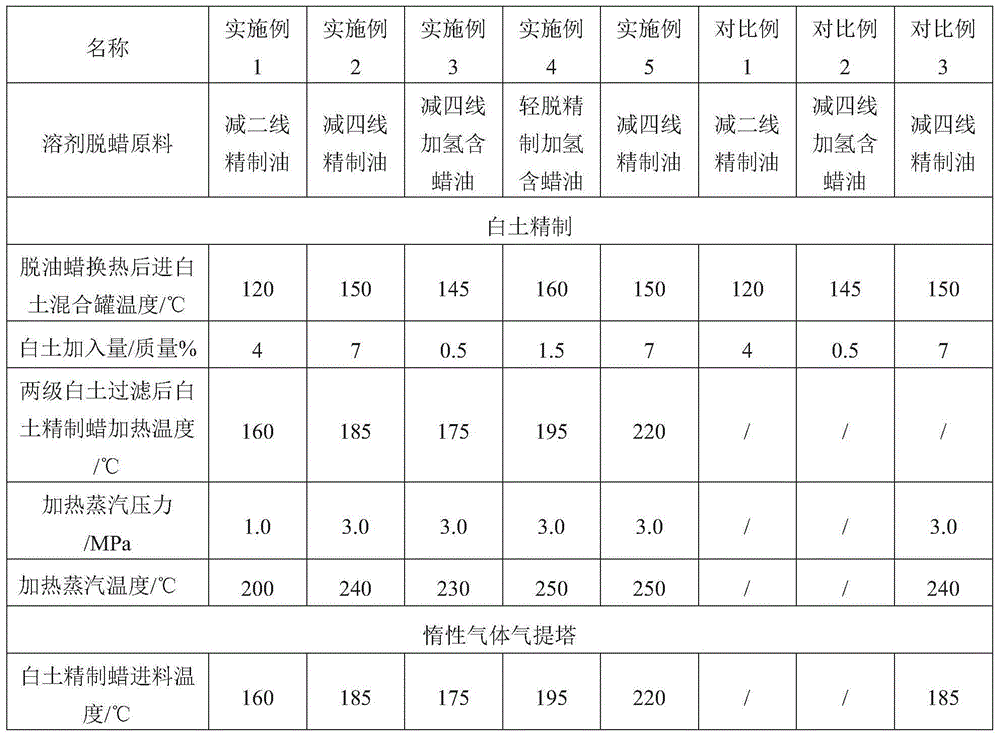

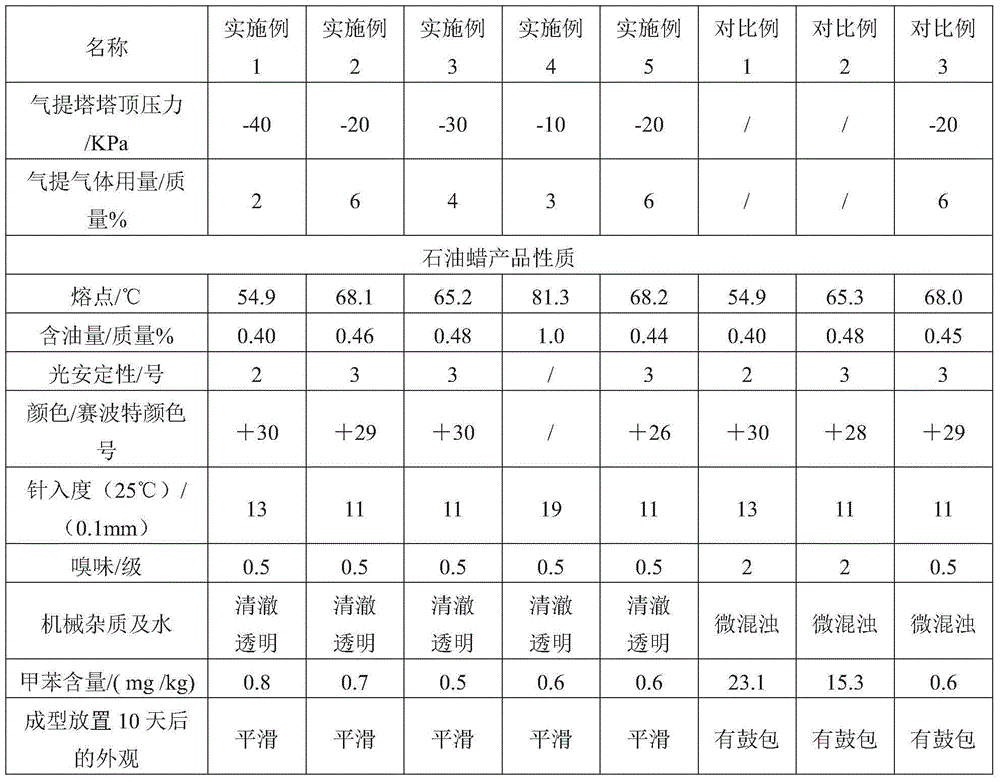

[0053] This example is used to illustrate the method for improving the smell and appearance of petroleum wax provided by the present invention.

[0054] The solvent dewaxing device uses the refined oil with the second-line solvent as the raw material for dewaxing and deoiling, and the deoiled wax enters the deoiled wax storage tank for storage (toluene solvent content in the deoiled wax is 126mg / kg).

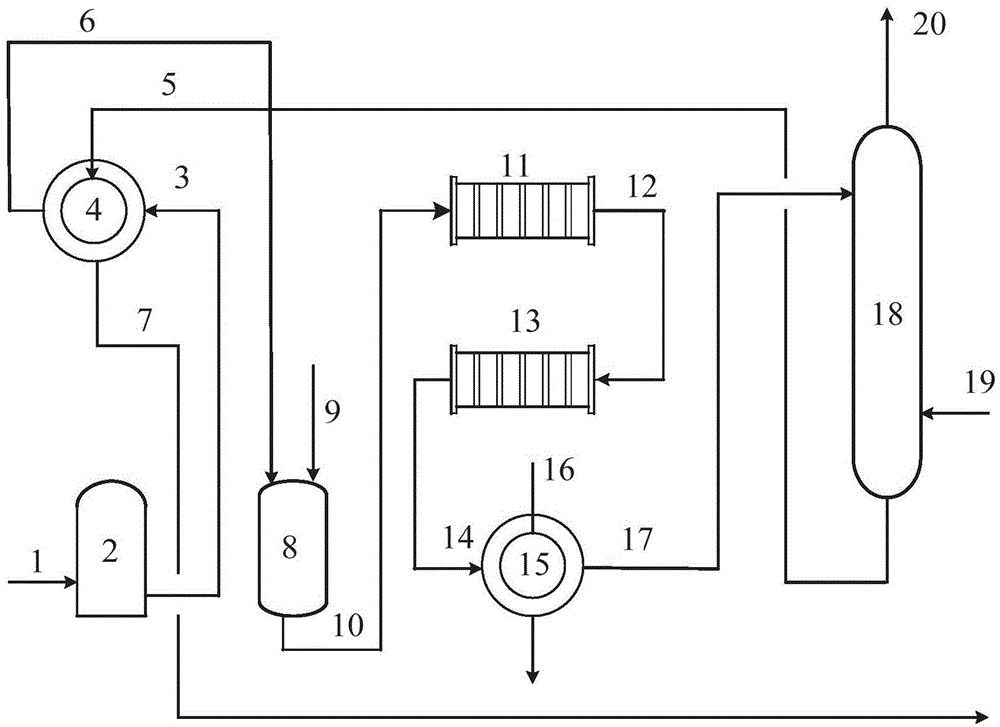

[0055] Such as figure 1 As shown, after heat exchange between the deoiled wax from the deoiled wax storage tank and the deodorized and dehydrated petroleum wax product from the bottom of the inert gas stripping tower to 120°C, the deoiled wax is sent to the clay refining mixing tank and activated clay Mixing, the amount of activated clay added is 4% of the deoiled wax quality. The mixture of deoiled wax and clay coming out of the clay mixing tank enters the first-stage and second-stage plate-and-frame filters in turn to filter and remove clay. The white clay refined wax flowin...

Embodiment 2

[0057] This example is used to illustrate the method for improving the smell and appearance of petroleum wax provided by the present invention.

[0058] The solvent dewaxing device uses the fourth-line solvent-refined oil as the raw material for dewaxing and deoiling, and the deoiled wax enters the deoiled wax storage tank for storage (toluene solvent content in the deoiled wax is 83mg / kg).

[0059] After heat exchange between the deoiled wax from the deoiled wax storage tank and the deodorized and dehydrated petroleum wax product from the bottom of the inert gas stripping tower to 150°C, the deoiled wax is sent to the clay refining mixing tank to mix with activated clay, and the activity The amount of white clay added is 7% of the deoiled wax quality. The mixture of deoiled wax and clay coming out of the clay mixing tank enters the first-stage and second-stage plate-and-frame filters in turn to filter and remove clay. The white clay refined wax flowing out of the second-stag...

Embodiment 3

[0061] This example is used to illustrate the method for improving the smell and appearance of petroleum wax provided by the present invention.

[0062] The solvent dewaxing unit uses four-line hydrotreated waxy oil as raw material for dewaxing and deoiling, and the deoiled wax enters the deoiled wax storage tank for storage (the toluene solvent in the deoiled wax is 56 mg / kg).

[0063] After heat exchange between the deoiled wax from the deoiled wax storage tank and the deodorized and dehydrated petroleum wax product from the bottom of the inert gas stripping tower to 145°C, the deoiled wax is sent to the clay refining mixing tank to mix with activated clay, and the activity The amount of white clay added is 0.5% of the deoiled wax mass. The mixture of deoiled wax and clay coming out of the clay mixing tank enters the first-stage and second-stage plate-and-frame filters in turn to filter and remove clay. The white clay refined wax flowing out of the second-stage plate and fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com