Suctioning device for large artificial water bodies

A technology for suction equipment and water bodies, which is applied in the field of suction equipment and can solve problems such as inability to use large-scale applications, damage to coatings, and disabling of large-scale artificial water bodies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0088] A suction device according to the present invention was fabricated and installed in a 3.7 acre large body of water.

[0089] The water body includes an LLDPE (Linear Low Density Polyethylene) liner which is installed on sandy soil creating an irregular bottom which must be thoroughly cleaned to maintain proper water color and tone. Other technologies cannot clean such large bodies of water, and therefore the suction device according to the invention was developed and tested at the site.

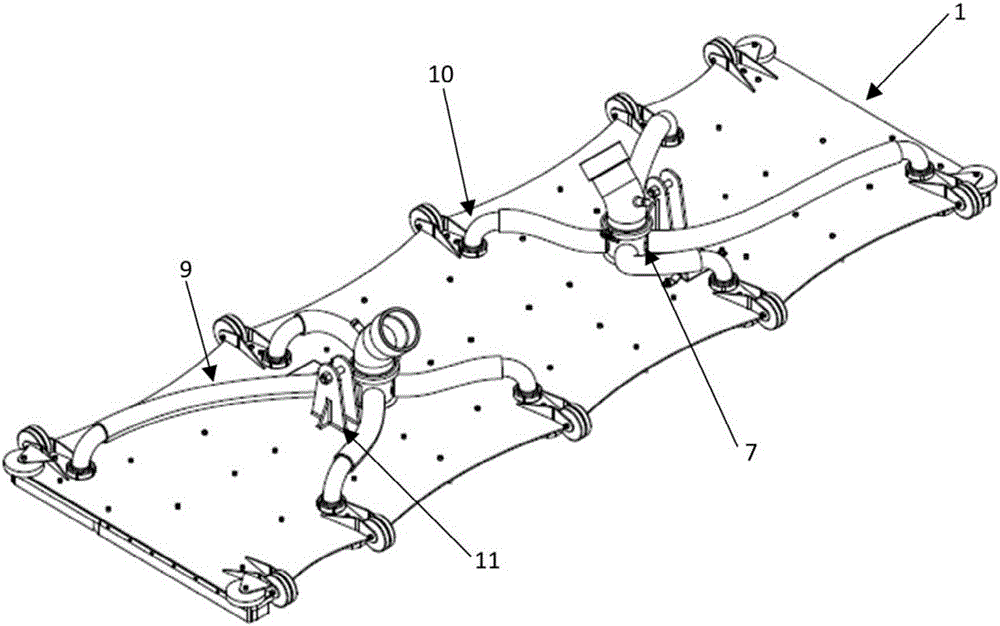

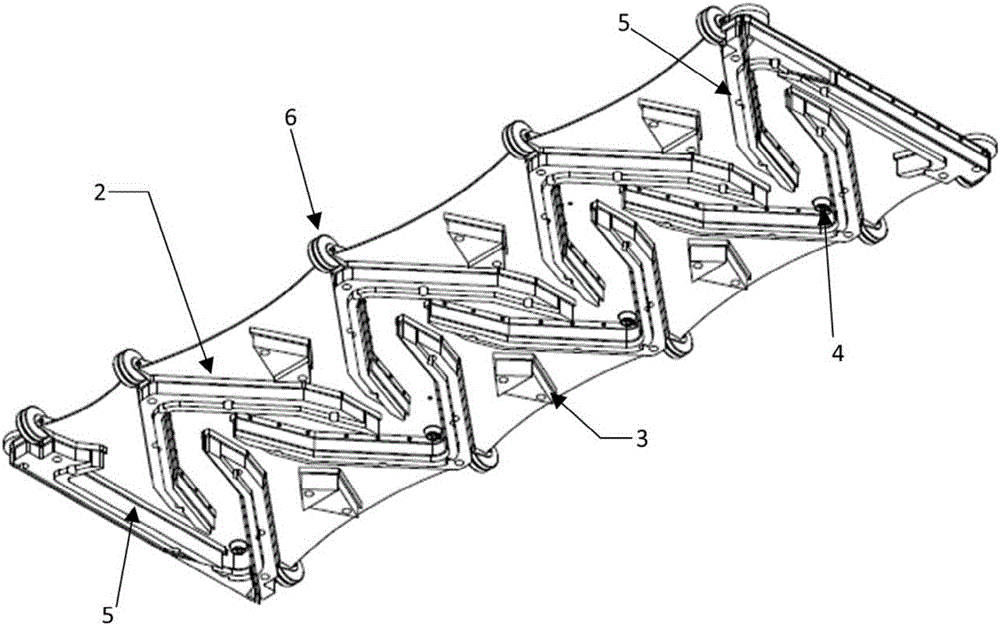

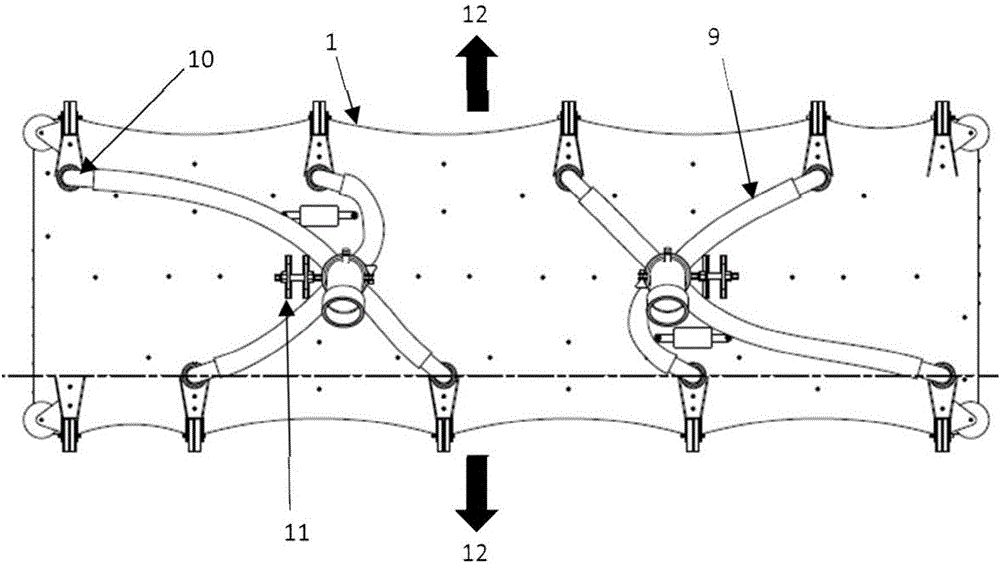

[0090] The suction device consisted of a flexible sheet constructed of polycarbonate with a thickness of 10 mm to provide the required flexibility. The suction device has approximately 3m 2 surface area and has general dimensions of 3 meters long and 1 meter wide. The height of the suction device is about 6 cm, which only allows suction of the bottom stream containing impurities and debris, but not clean water which would render the treatment inefficient.

[0091] The brushes are m...

example 2

[0103] A suction device according to the present invention was fabricated and installed at a large body of water of 20 acres. Large bodies of water have bottoms covered with LLDPE liners installed on sandy soils creating an irregular bottom that must be thoroughly cleaned to maintain proper water color and tone in the large body of water. Due to the recreational nature of the project, cleaning operations are carried out at night, and therefore the suction equipment and propulsion means include specific facilities (such as additional lights) and systems (such as GPS) to achieve this.

[0104] The suction device has a flexible sheet constructed of 316 steel with a thickness of 5mm to provide the flexibility required and the weight required to keep the device underwater and avoid while rising from the bottom. By providing steel sheets, the weight is distributed along the entire unit, thus increasing the stability of the unit. The surface of the suction device is approx. 3m 2 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com