Mechanical apple bagging machine

A bagging machine, apple technology, applied in plant protection covers, botanical equipment and methods, gardening, etc., can solve the problems of not a small number, two or three thousand expenditures, etc., to achieve high safety and improve work efficiency , the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

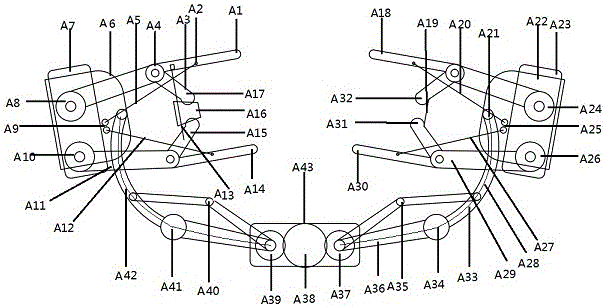

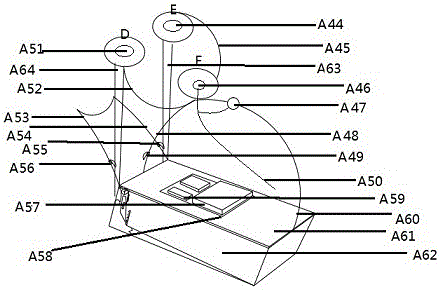

[0031] The invention provides a mechanical apple bagging machine. Its features are: composed of automatic output box, automatic bag support mechanism and sealing mechanism.

[0032] The parts of a kind of mechanical apple bagging machine described therein include: the left front movable finger A1, the limit arm hole A2, the left front clamp arm A3, the connection hole A4, the left limit arm A5, the left positioning plate A6, and the left gear box A7 , Front left mechanical arm with gear A8, limit arm connection hole A9, left rear mechanical arm with gear A10, left mechanical arm A11, left limit arm A12, rotating shaft A13, left rear movable finger A14, left rear clamp arm A15, movable Tongue A16, trigger plate A17, right front movable finger A18, limit shaft A19, right limit arm A20, right mechanical arm connection A21, right positioning plate A22, right gear box A23, right front mechanical arm with gear A24, limit arm Connection hole A25, right rear mechanical arm with gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com