Design method for filling porous grid structure in bone implantation body

A design method and grid structure technology, applied in the field of biomedicine, can solve problems such as unstable performance and geometric contour distortion, and achieve the effect of reducing the equivalent elastic modulus, good mechanical properties, and realizing lightweight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

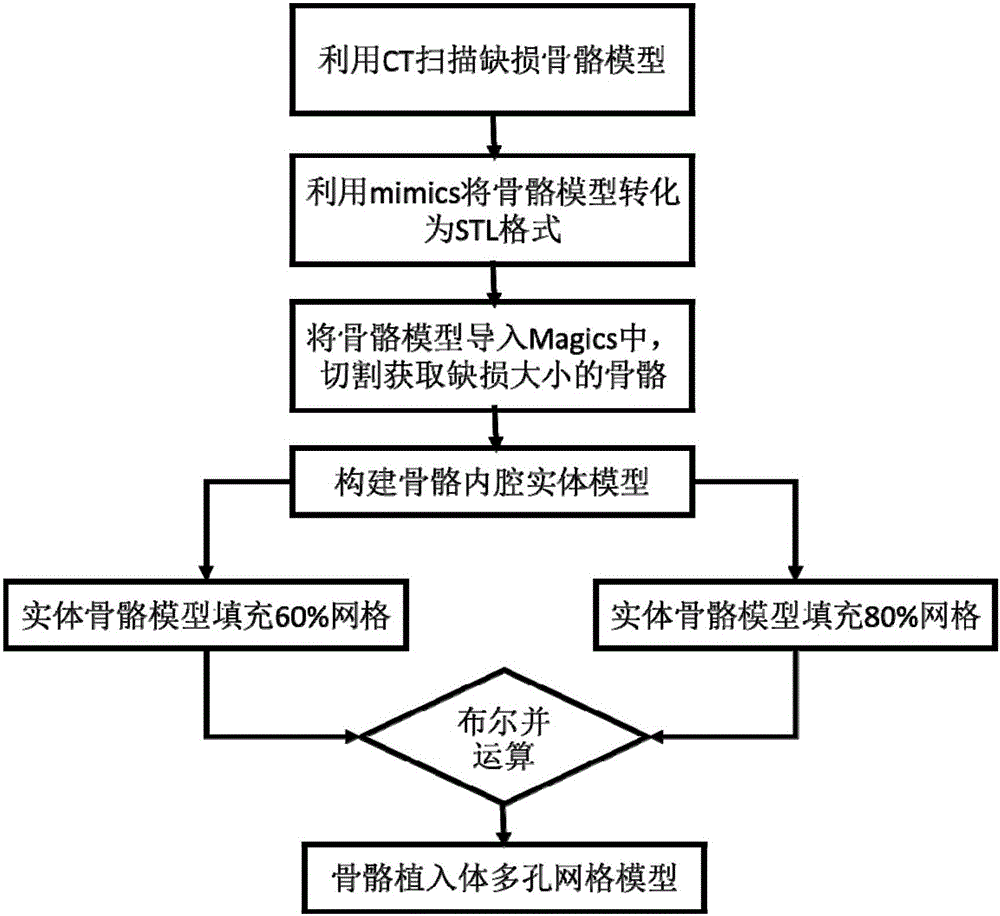

[0032] The design process of the human bone porous mesh structure implant of the present invention is as attached figure 1 , The specific implementation is as follows:

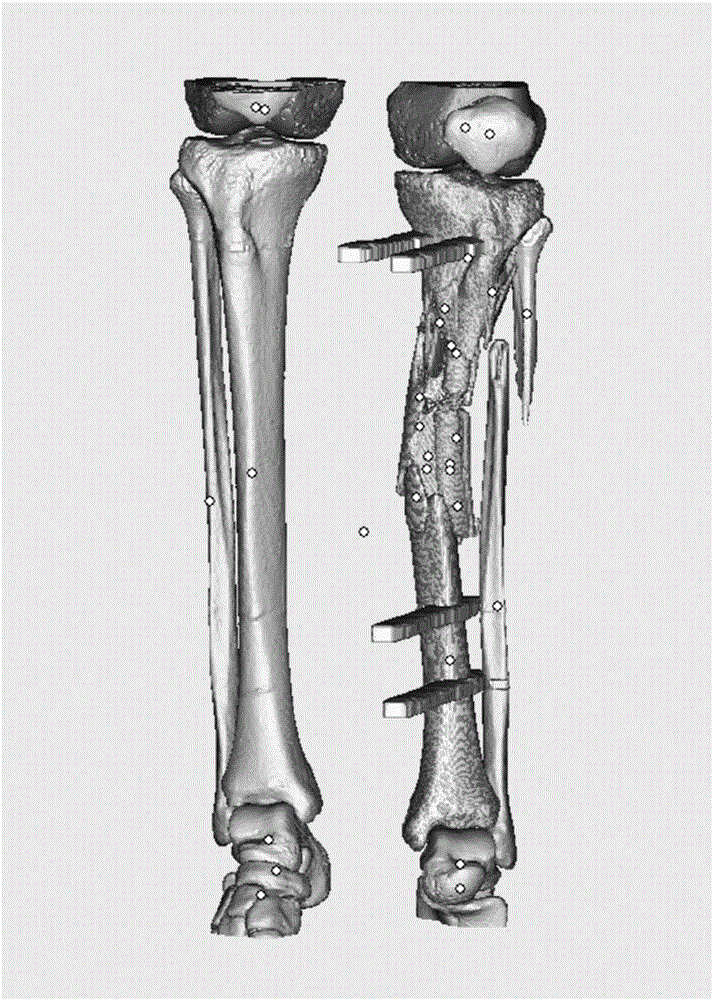

[0033] Step 1: Use medical imaging technology to obtain the tomographic data of the patient’s bone defect, extract its contour data through image processing, and then import the three-dimensional reconstruction software mimics to obtain a bone entity model with individual matching, including a complete bone model and For the defective bone model, convert the model file format to STL;

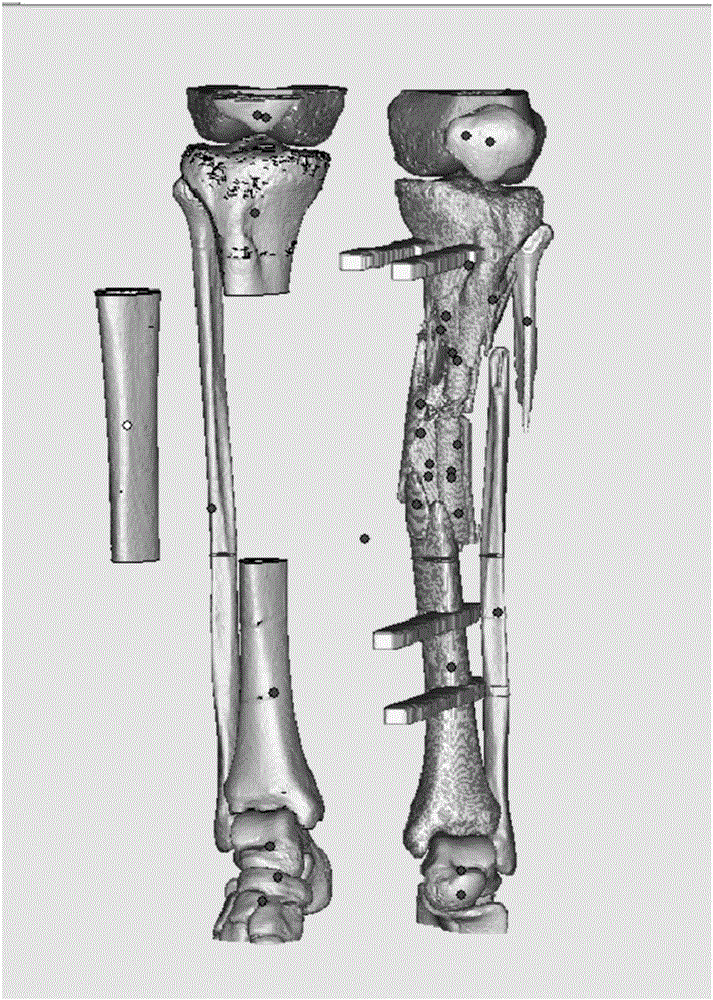

[0034] Step 2: Open the 3D model processing software Magics, import the STL model of the skeleton into Magics, compare the complete bone and the defect bone, use the cutting tool in the toolbar to intercept the complete bone and the bone model of the same size as the defect, and save the model;

[0035] Step 3: Import the bone model intercepted and saved in Step 2 into Magics. Use the marking function of the software to select and mar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com