Blade structure and knife roller of double-shaft shredding machine

A double-shaft shredder and blade technology, applied in the field of shredders, can solve the problems of large proportion of tire pieces, large length, easy connection instability, and reduced equipment output, etc., to achieve good material-carrying effect and enhanced shearing effect , The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

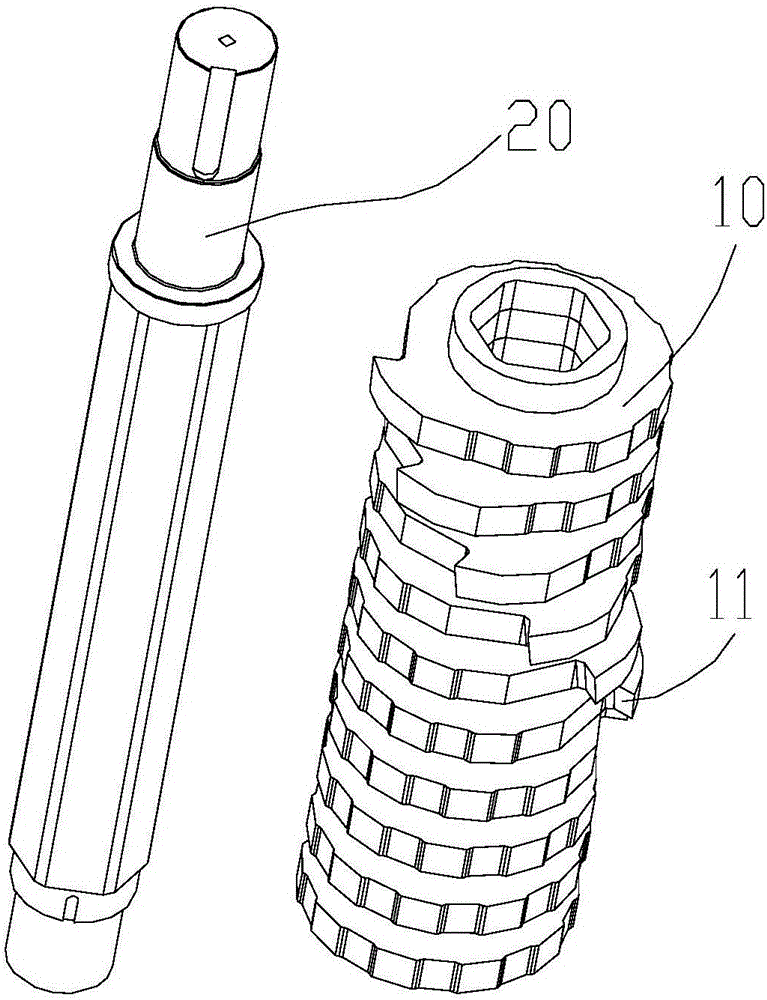

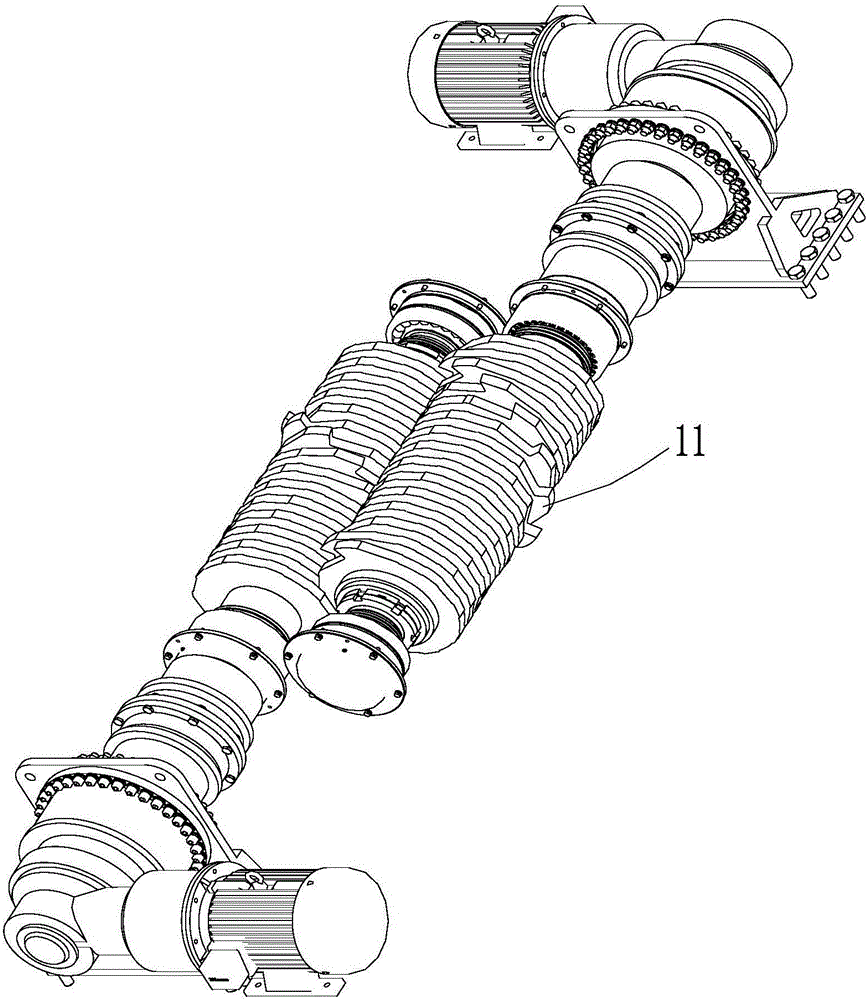

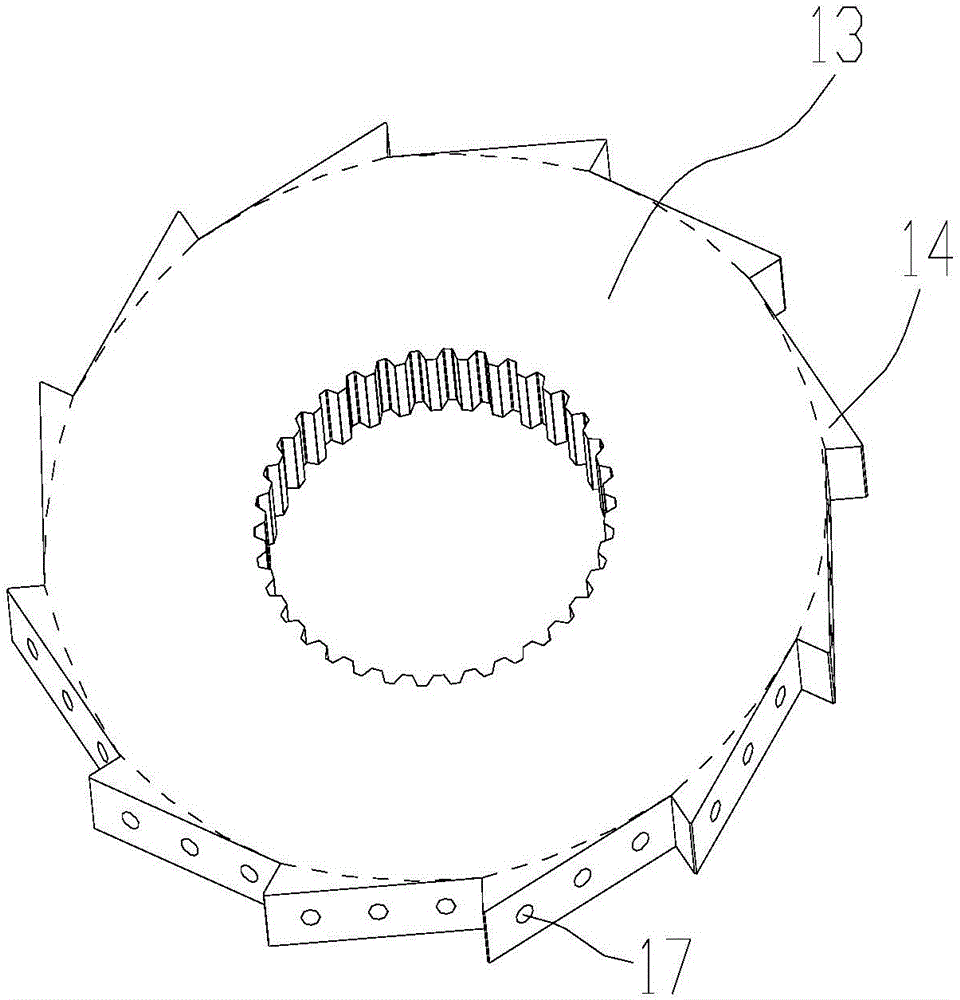

[0034] Such as figure 1 As shown, it is an explosion schematic diagram of the cutter roller in the prior art biaxial shredder, the cutter roller mainly includes a cutter shaft 20 and several blade structures 10, and the center of each blade structure 10 is provided with a regular hexagonal through hole, and The main part of the cutter shaft 20 is designed as a regular hexagonal prism, and the cutter shaft 20 passes through several regular hexagonal through holes on the blade structure 10 in turn, so that the blade structure 10 is fixed on the cutter shaft 20 . In this type of cutter roll, the blade structure 10 adopts an integrated design, and each blade structure is provided with a cutter claw 11 that mainly functions as a belt. Such as figure 2 As shown, the two knife rollers are arranged side by side. During the working process, the two knife rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com