Welding device for structural steel with variable cross sections

A welding device and variable cross-section technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of welding torch position tracking, difficult to adapt, difficult to achieve precise welding, etc., and achieve the effect of accurate welding effect and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

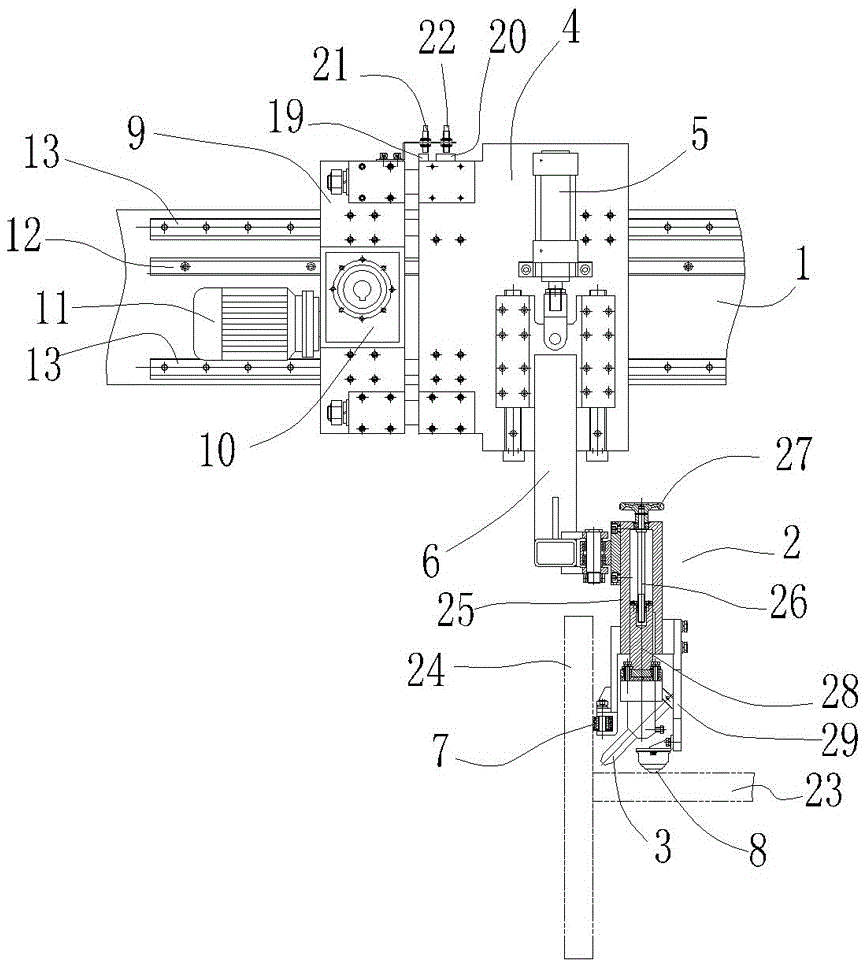

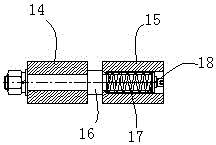

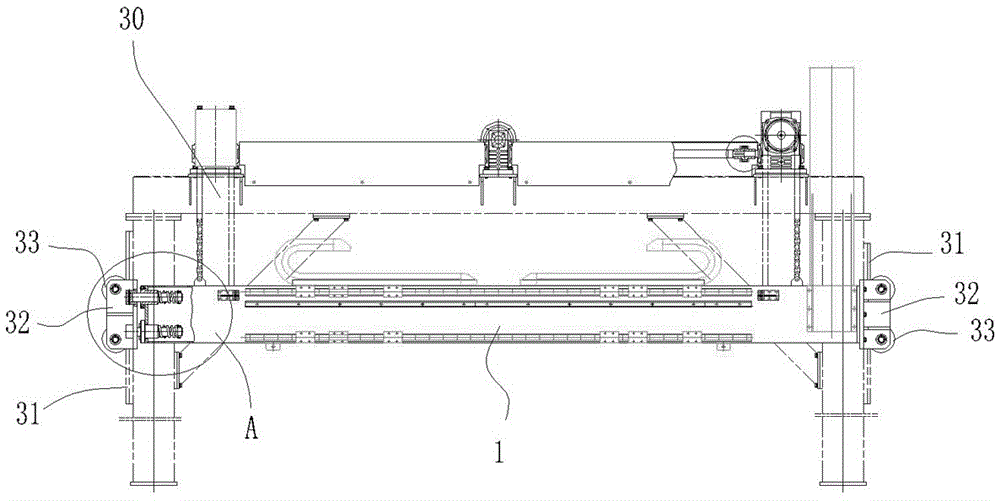

[0031] refer to figure 1 , figure 2 , comprising a base, a gantry frame 30 slidingly arranged on the base, a beam 1 arranged on the gantry frame 30 and capable of lifting, and a welding frame 2, the welding frame 2 is provided with a welding torch 3, the The beam 1 is provided with a moving plate 4 that can slide horizontally along the beam 1 left and right, and the moving plate 4 is provided with a vertically arranged cylinder 5, and the piston rod of the cylinder 5 is connected to the floating frame 6. The floating frame 6 is pivotally connected to the welding frame 2 through a vertical pivot, and the welding frame 2 is provided with a lateral guide wheel 7 . In this embodiment, the lower end of the welding frame 2 is provided with a universal ball head 8, and the moving plate 4 is provided with a vertical slide rail, and the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com