An adjustment module for a fine-tuning machine

A fine-tuning machine and module technology, applied in the direction of wrenches, metal processing equipment, screwdrivers, etc., can solve the problems that it is difficult to accurately calibrate the workpiece, the phenomenon of follow-up occurs from time to time, and the adjustment accuracy of the bit is affected, so as to achieve stable and firm connection , Convenient and fast loading and unloading, prevent the screw from rotating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

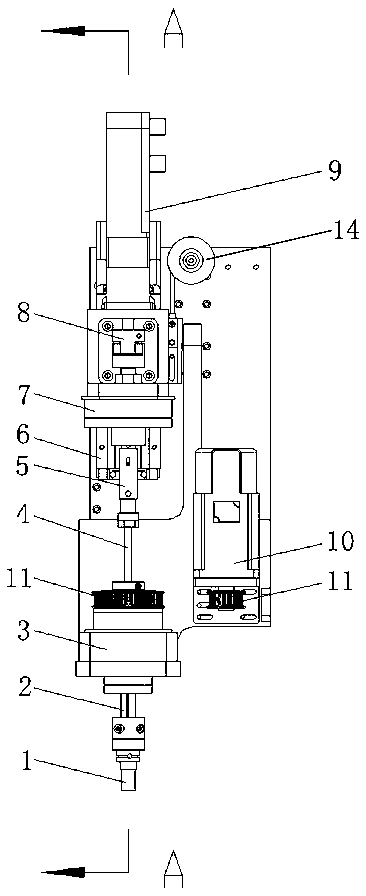

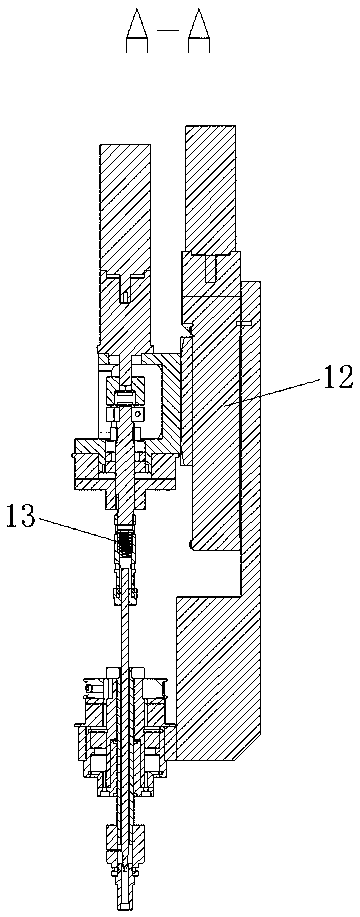

[0027] Such as figure 1 As shown, an adjustment module for a fine-tuning machine in this embodiment includes: a sleeve 1, a spline shaft 2, a nut holding brake 3, a bit 4, a handle 5, a flange bearing 6, a bit holding Tight brake 7, shaft coupling 8, lock paying motor 9, nut locking motor 10, synchronous pulley 11, transfer electric cylinder 12, spring 13 and constant force spring 14 up and down.

[0028] The connection relationship of the above-mentioned components is as follows: the batch head 4 is connected with the flange bearing 6 through the tool handle 5 connected to the upper end, and the top of the flange bearing 6 is sequentially connected with a batch head holding brake 7 and a shaft coupling 8 And the locking motor 9; the lower part of the batch head 4 runs through the nut holding brake 3, and is connected with the sleeve 1 through the spline shaft 2 sleeved at the bottom; the coupling 8 is connected with the upper and lower electric cylinder 12 is slidingly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com