Automatic-ejecting-out injection mold for dust guard

A technology for injection molds and dust covers, which is applied in the field of self-ejection dust cover injection molds, and can solve the problems of dust cover damage, inability to achieve cooling, and easy generation of flashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

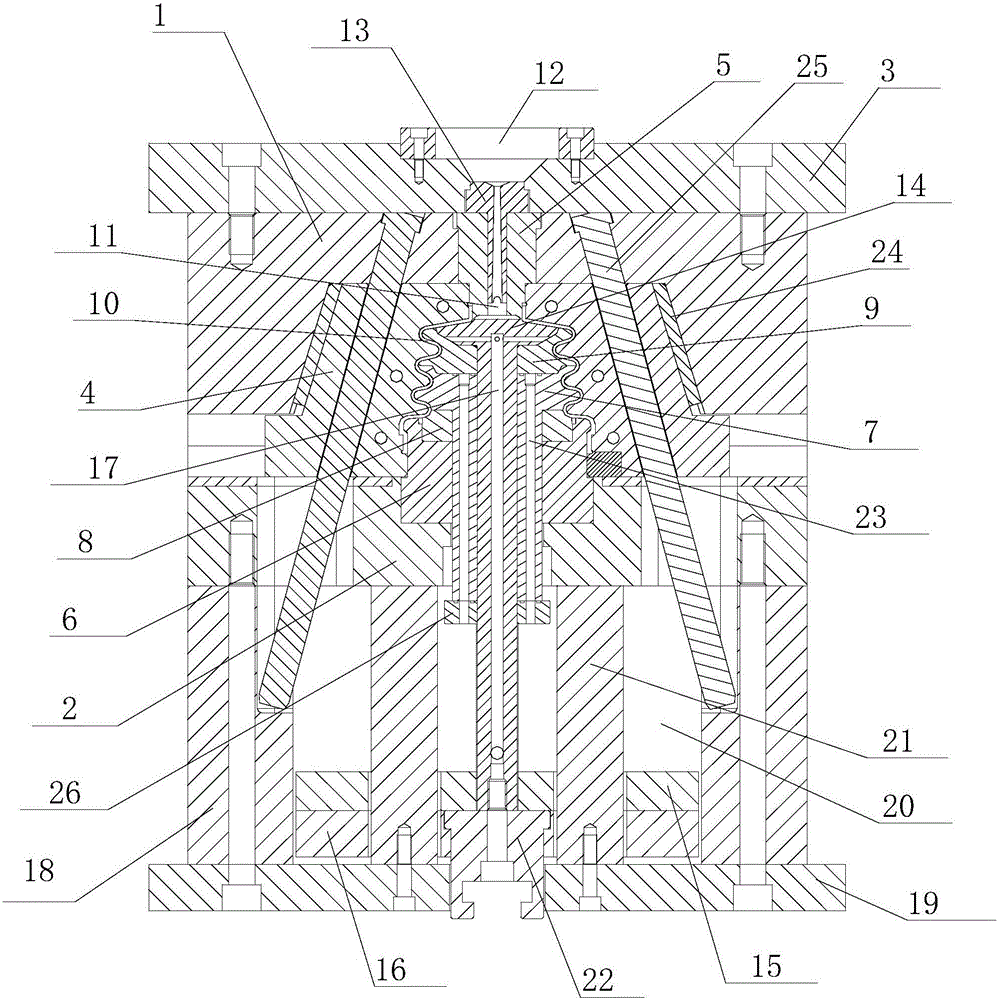

[0018] refer to figure 1 , the present invention proposes a self-ejection dust cover injection mold, including a core assembly, an upper template 1, a lower template 2, an upper mold fixing plate 3, a half block 4, an ejector assembly, and a plurality of inclined guide pillars 25, in:

[0019] The mold core assembly includes an upper mold core 5, a lower mold core 6, and a movable middle mold core 7. The upper mold core 5 is located above the lower mold core 6, and the upper mold core 5 is installed on the upper template 1. The lower mold core 6 is installed on the lower template 2, and the lower mold core 6 upper end is provided with a lower mold core insert 8. The movable core 7 is set in the lower core 6, the upper end of the movable core 7 is provided with a core insert 9, the bottom of the movable core 7 is provided with a limit plate 26, and the movable core 7 is provided with a plurality of The water channels 23 are circumferentially distributed around the central axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com