High-speed cable-driven wire laying device

A cable-arranging device and rope-driven technology, applied in the field of mechanical transmission, can solve the problems of decreased position accuracy and inability to achieve motion effects, and achieve the effects of avoiding motion errors, avoiding transmission errors, and improving motion accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

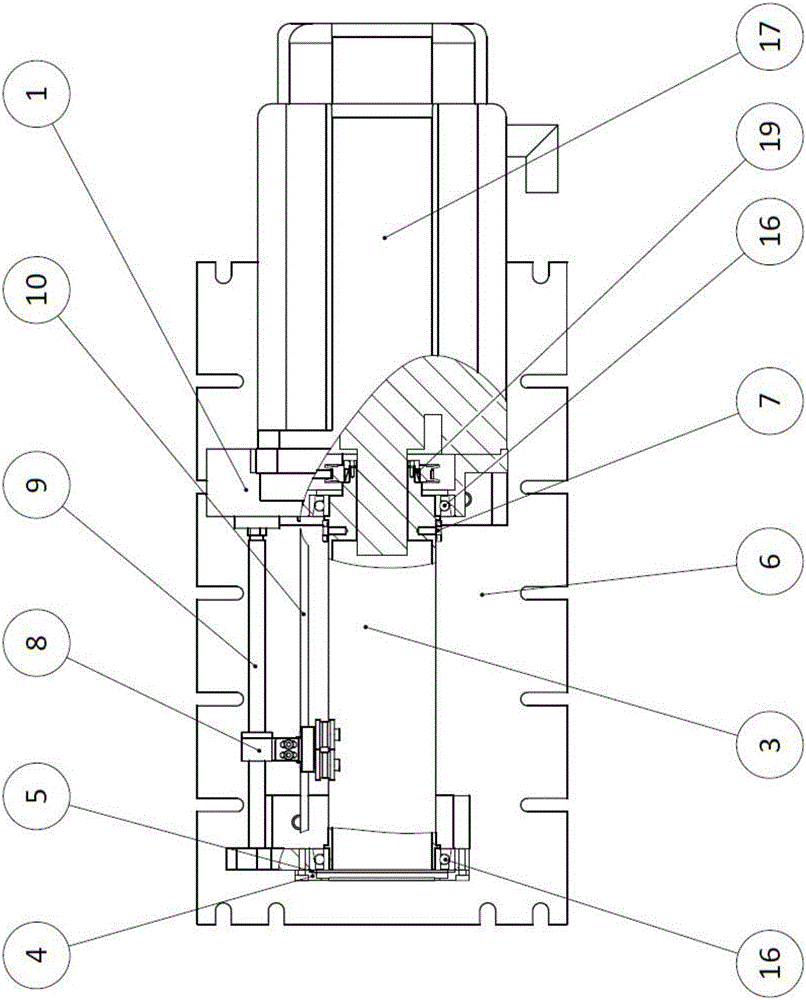

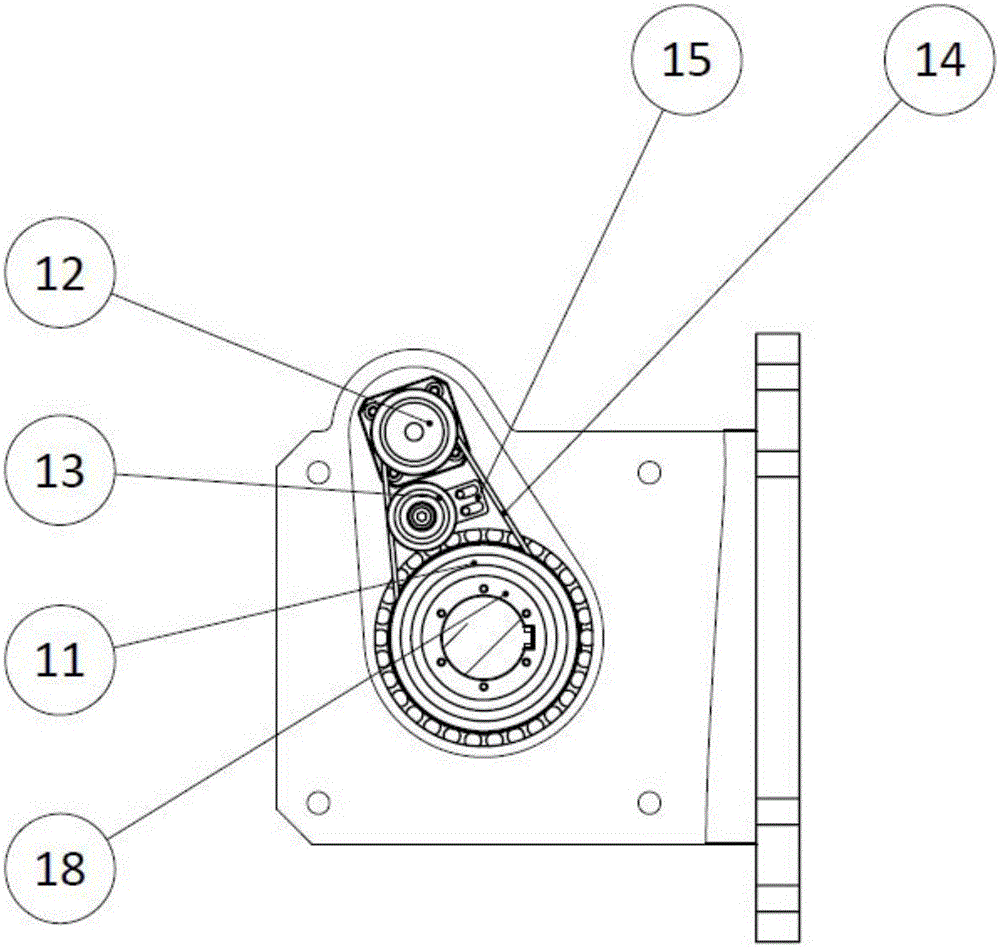

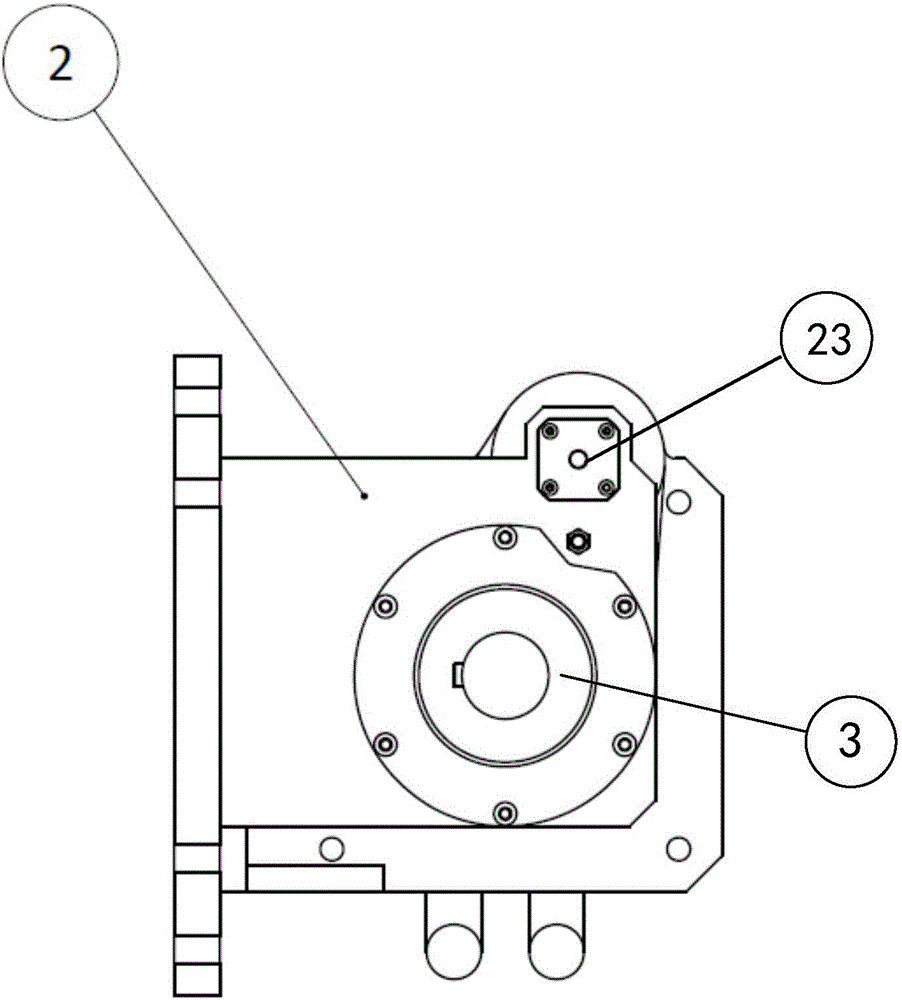

[0032] The following will describe the rope-driven cable arranging device according to the embodiment of the present invention in detail with reference to the accompanying drawings.

[0033] Please also refer to Figure 1 to Figure 5 , the rope-driven wire arranging device 100 using a ball screw as the wire rope guide provided by the embodiment of the present invention mainly includes a motor, a winding shaft, a lead screw, a wire arranging mechanism guide pulley and a guide rod.

[0034] The motor 17 is arranged on a motor support 1 and fixed on a support base 6 , and the motor 17 has an output shaft. The rope-driven cable arrangement 100 further includes a shaft support 2 fixed on the support base 6 and spaced apart from the motor 17 . The side of the shaft support 2 away from the motor 17 is provided with a bearing washer 5 and a bearing cover 4 to protect the bearings in the shaft support 2 .

[0035] The winding shaft 3 has two opposite ends, one end is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com