Domestic sewage and industrial wastewater classified filtering technique achieved through mineral cotton fibers

A technology of mineral wool fiber and graded filtration, which is applied in the fields of filtration treatment, energy waste water treatment, water/sewage treatment, etc., and can solve problems such as reduction of aquatic animals and plants, pollution of rivers and lakes, and decline of drinking water quality, achieving good prospects, filtration Good effect and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

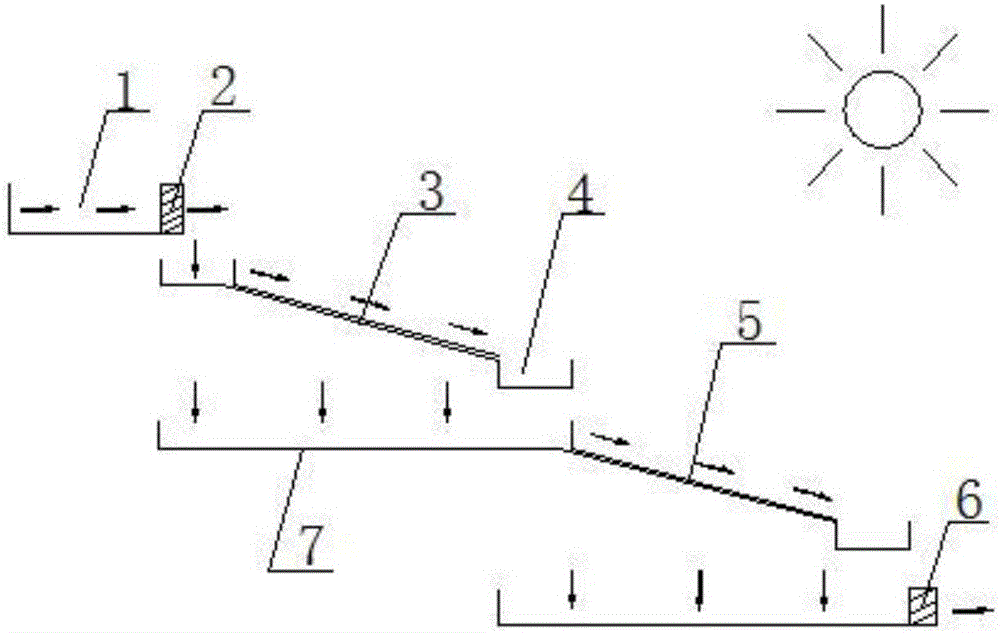

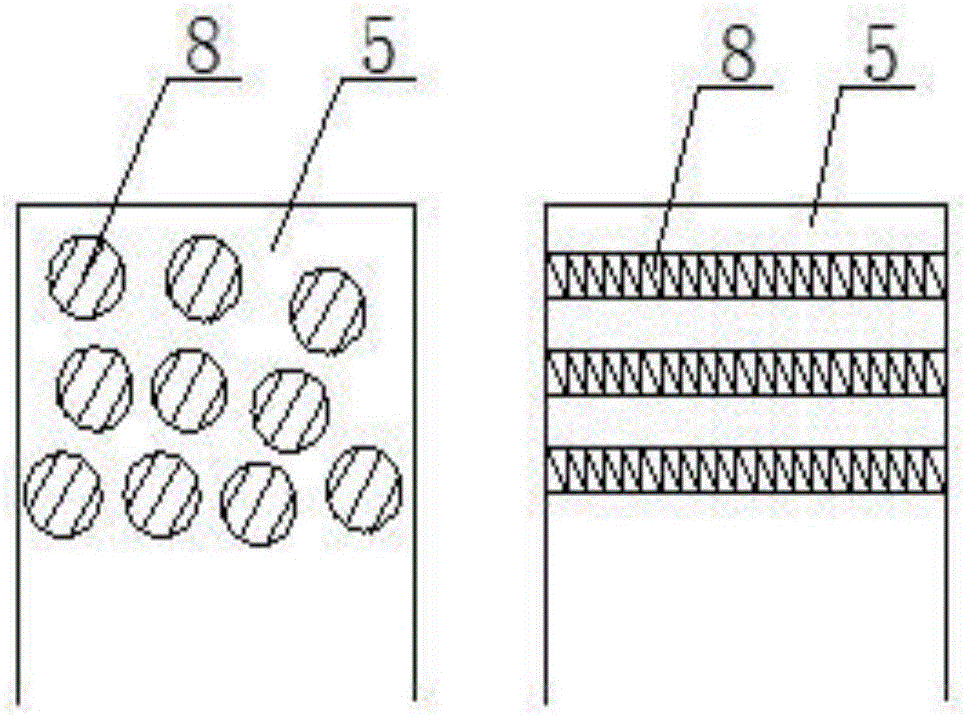

[0022] Such as figure 1 and figure 2 As shown, a mineral wool fiber graded filtration technology for domestic sewage and industrial wastewater is characterized in that the graded filtration technology includes three processes: modified rock wool filtration, solar catalytic reaction and glass microfiber filtration.

[0023] As a further optimization of the scheme, the modified rock wool filtering process is to filter the sewage through the treated waste rock wool.

[0024] The waste rock wool comes from the scraps of rock wool pipes and boards in the production process, and the raw materials for industrial heating network pipes, equipment insulation, building walls, and roof insulation to be replaced after a certain number of years.

[0025] The treatment process of described waste rock wool is: (a) put into the polymerized FeSO containing 10% 4 Soak in the solution; (b) use 60KHz frequency ultrasonic vibration for 20 minutes during the soaking process to ensure that polyfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com