Cross-linking agent for cathode electrophoretic paint and production process thereof

A cathodic electrophoresis and production process technology, which is applied in the field of chemical industry, can solve the problems that the cross-linking agent cannot meet the corresponding requirements, and achieve the effect of increased anti-corrosion performance, strong operability, and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

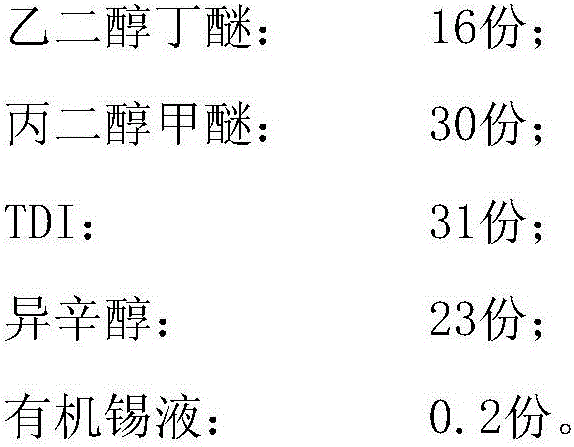

[0026] A crosslinking agent for cathodic electrophoretic paint, made of the raw materials of the following components in proportion by weight:

[0027]

[0028] The operation process is as follows:

[0029] (1) Check whether the special low-temperature kettle is clean, and whether the pipes and valves are in place.

[0030] (2) Use a vacuum to suck in the formulated amount of TDI, pass water through the shaft sleeve, and start stirring to add the formulated amount of organotin liquid.

[0031] (3) When the material temperature rises to 60°C, start to drop the isooctyl alcohol pumped into the metering tank in advance, and then add ethylene glycol ether dropwise after the dropwise addition is completed. This reaction is an exothermic reaction, pay attention to temperature changes, control the rate of addition at 300 kg / hour, and control the temperature between 60-65°C.

[0032] (4) After the dropwise addition, keep warm at 70-75°C for 2 hours, then raise the temperature to ...

Embodiment 2

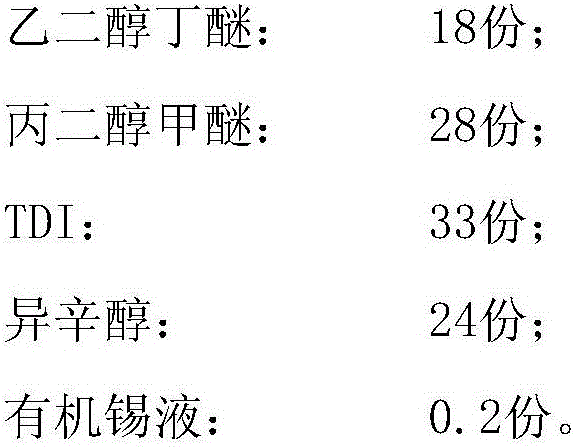

[0034] A crosslinking agent for cathodic electrophoretic paint, made of the raw materials of the following components in proportion by weight:

[0035]

[0036] The operation process is as follows:

[0037] (1) Check whether the low-temperature kettle is clean and whether the pipes and valves are in place.

[0038] (2) Use a vacuum to suck in the formulated amount of TDI, pass water through the shaft sleeve, and start stirring to add the formulated amount of organotin liquid.

[0039] (3) When the material temperature rises to 65°C, start to drop the isooctyl alcohol pumped into the metering tank in advance, and then add ethylene glycol ether dropwise after the dropwise addition is completed. This reaction is an exothermic reaction, pay attention to temperature changes, control the rate of addition at 260 kg / hour, and control the temperature between 60-65°C.

[0040] (4) After the dropwise addition, keep warm at 70-75°C for 2 hours, then raise the temperature to 90°C, kee...

Embodiment 3

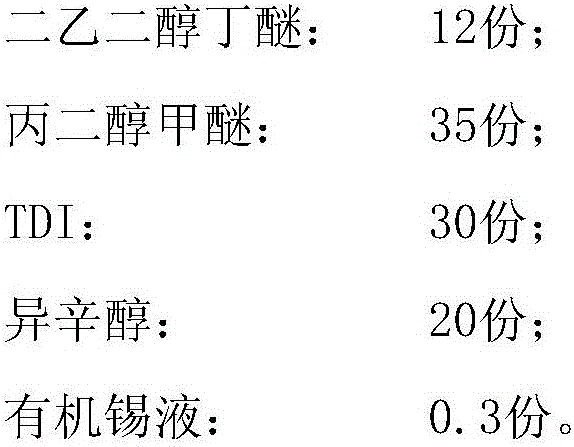

[0042] A crosslinking agent for cathodic electrophoretic paint, made of the raw materials of the following components in proportion by weight:

[0043]

[0044] The operation process is as follows:

[0045] (1) Check whether the low-temperature kettle is clean and whether the pipes and valves are in place.

[0046] (2) Use a vacuum to suck in the formulated amount of TDI, pass water through the shaft sleeve, and start stirring to add the formulated amount of organotin liquid.

[0047] (3) When the material temperature rises to 55°C, start to drop the isooctyl alcohol pumped into the metering tank in advance, and then add ethylene glycol ether dropwise after the dropwise addition is completed. This reaction is an exothermic reaction, pay attention to temperature changes, control the rate of addition at 260 kg / hour, and control the temperature between 60-65°C.

[0048] (4) After the dropwise addition, keep the reaction at 80°C for 4 hours. After the heat preservation, add p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com