Efficient sand prevention and dust removal device for cooling tower

A dust removal device and cooling tower technology, applied in water shower coolers, cleaning heat transfer devices, damage protection, etc., can solve the problem of reducing the service life of equipment, preventing wind and sand at air inlets and outlets and dust removal, reducing device production efficiency, etc. problem, to achieve the effect of increasing the degree of corrosion resistance, increasing the anti-corrosion performance, and increasing the ability to resist wind and sand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

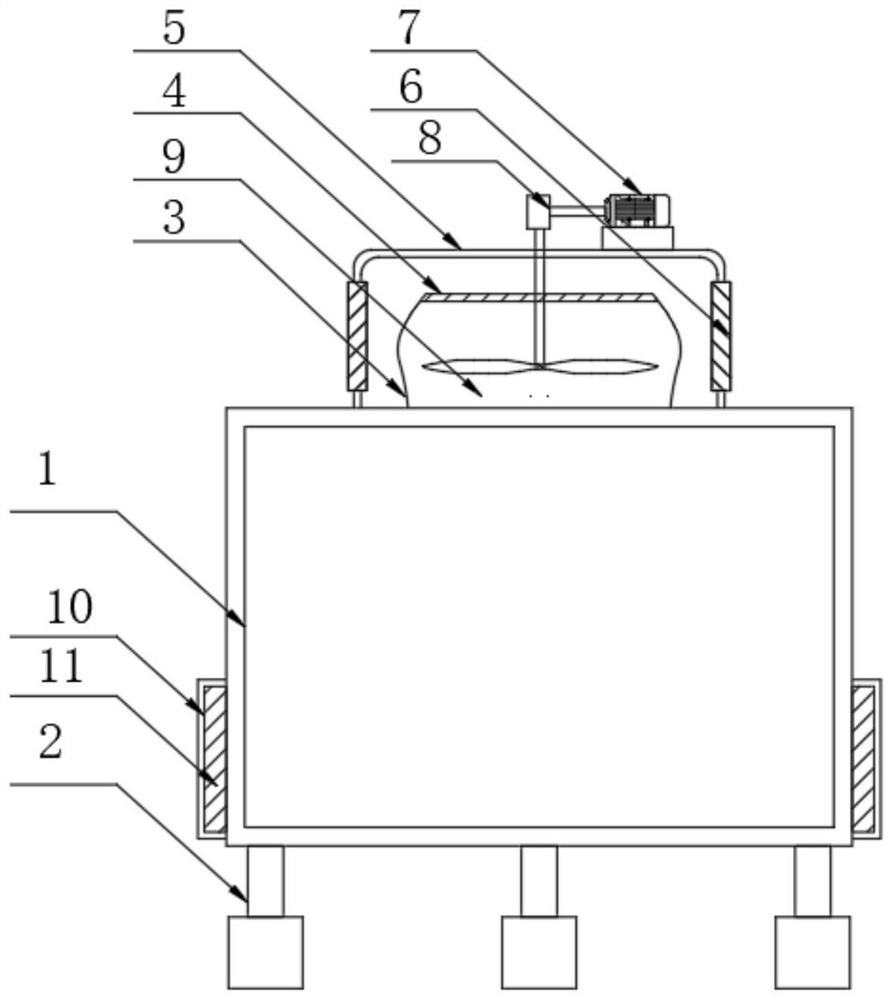

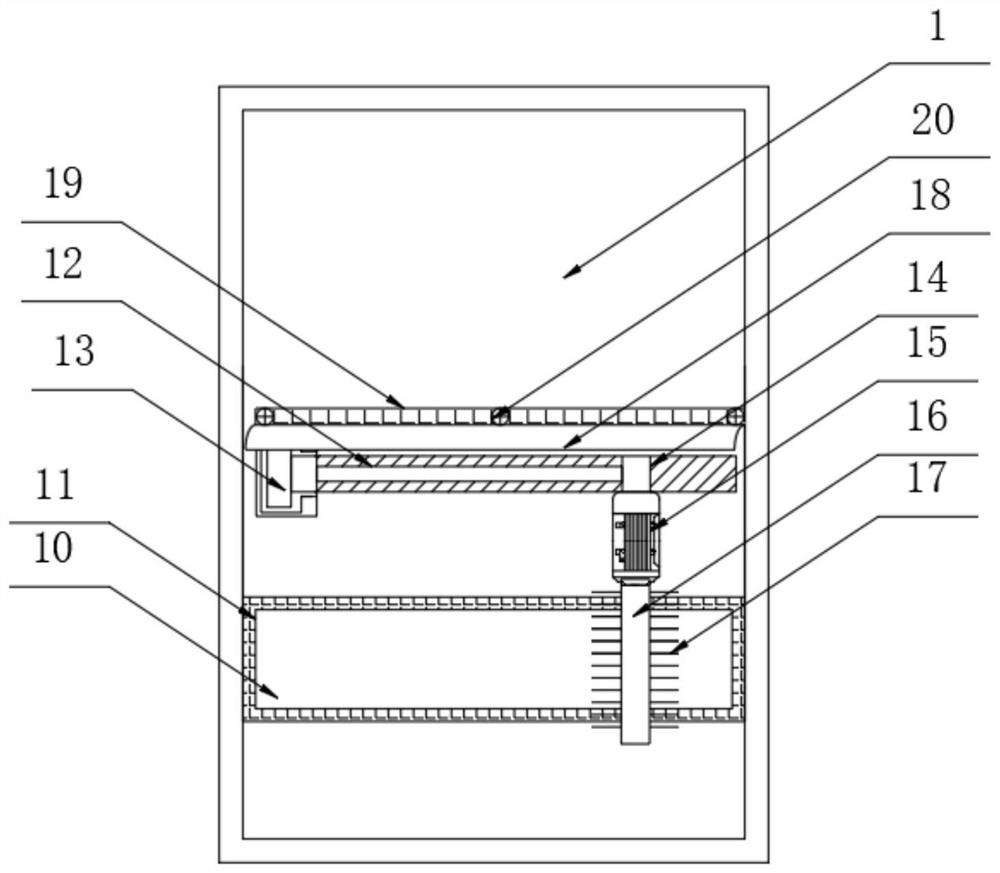

[0027] The specific implementation method is: drive the side connecting rod 81 through the motor 7, drive the side straight tooth plate 82 through the side connecting rod 81, make the side straight tooth plate 82 drive the bottom straight tooth plate 83, make the bottom straight tooth plate 83 pass through the bottom connecting rod 84 Driving exhaust fan 9 has not only solved power but also solved connection problem.

[0028] The working principle of the present invention:

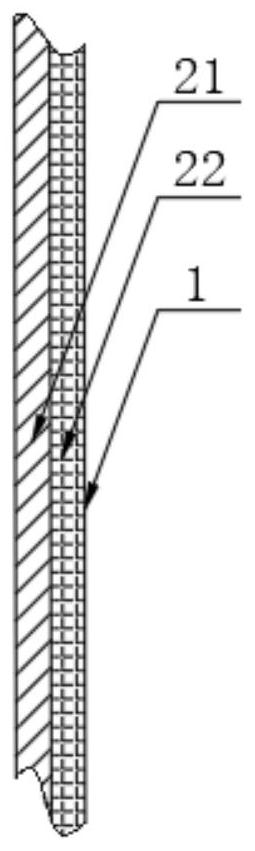

[0029] First assemble the parts of each part, then start the equipment, and carry out wind and sand prevention treatment on the equipment body 1 through the anti-sand net 4, the protective baffle 5, and the vents 6 on both sides of the protective baffle 5, and at the same time use the cylinder 13 to drive the connection The rod makes the slider 14 move, and the brush rod 16 is driven by the power motor 15, so that the bristles 17 perform dust removal operation on the dust-proof net 11. At the same time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com