Slag pot in steel mills produced by heatproof cast iron and production method thereof

A technology of heat-resistant cast iron and slag pots, which is applied in the field of slag pots for cast iron production. It can solve the problems that the slag pots cannot be filled with slag, and are prone to cracks and cracks, so as to save production costs, reduce the number of replacements, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

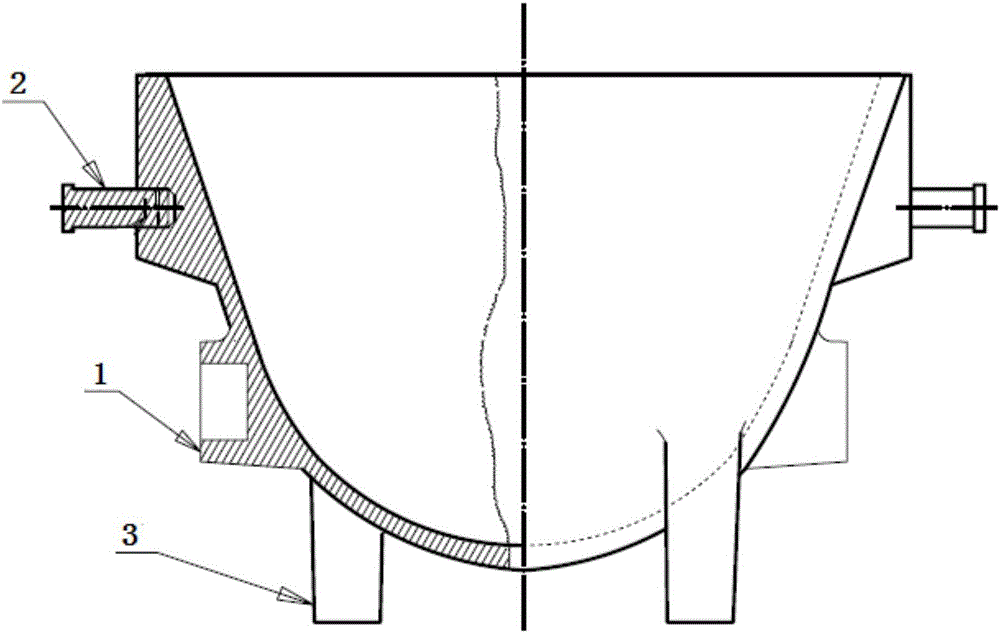

[0019] like figure 1 , 2 Shown in and 3, a steelworks slag tank produced by heat-resistant cast iron includes a tank body 1, and the tank body 1 is heat-resistant cast iron, consisting of the following components in weight percent: C: 3.4%; Si: 1.8 %; Mn: 0.80%; Cr: 2.0%; Mo: 0.60%; P<0.03%; S: 0.08%; Re: 0.03%, the balance iron.

[0020] The tank body is also provided with lifting lugs 2, and the lifting lugs 2 are cast in carbon steel; the lifting lugs 2 are composed of the following components in weight percentage: C: 0.22%; Si: 0.35%; Mn: 0.55%; P<0.035%; S:<0.035%, the balance is iron, the tensile strength of the lifting lug is 550MPa, the yield strength is 345MPa, and the elongation is 40%.

[0021] In addition, the bottom of the tank body 1 is provided with a slag tank support 3 .

[0022] Its preparation method is specifically:

[0023] The mold of the slag irrigation is made of northeast pine wood, and the molding material is furan resin sand. The proportion of ea...

Embodiment 2

[0042] Such as figure 1 and 2 As shown, a steel mill slag tank produced by heat-resistant cast iron includes a tank body 1, and the tank body 1 is heat-resistant cast iron, which is composed of the following components in weight percentage: C: 3.6%; Si: 2.2%; Mn: 0.6%; Cr: 2.2%; Mo: 0.35%; P<0.03%; S: 0.1%; Re: 0.02%, the balance is iron.

[0043] The tank body is also provided with a lifting lug 2, and the lifting lug 2 is cast in carbon steel; the lifting lug 2 is composed of the following components by weight percentage: C: 0.18%; Si: 0.45%; Mn: 0.3%; P<0.035%; S:<0.035%, the balance iron.

[0044] In addition, the bottom of the tank body 1 is provided with a slag tank support 3 .

[0045] Its preparation method is specifically:

[0046] The mold of the slag irrigation is made of northeast pine wood, and the molding material is furan resin sand. The proportion of each addition is furan resin: curing agent: sand = 1.3:0.78:100, and the tensile strength of the resin sand ...

Embodiment 3

[0056] Such as figure 1 and 2 As shown, a steel factory slag tank produced by heat-resistant cast iron includes a tank body 1, and the tank body 1 is heat-resistant cast iron, which is composed of the following components in weight percentage: C: 3.5%; Si: 2.0%; Mn: 0.7%; Cr: 2.1%; Mo: 0.5%; P<0.03%; S: 0.09%; Re: 0.025%, the balance is iron.

[0057] The tank body is also provided with lifting lugs 2, and the lifting lugs 2 are cast in carbon steel; the lifting lugs 2 are composed of the following components by weight percentage: C: 0.2%; Si: 0.4%; Mn: 0.45%; P<0.035%; S:<0.035%, balance iron.

[0058] In addition, the bottom of the tank body 1 is provided with a slag tank support 3 .

[0059] Its preparation method is specifically:

[0060] The mold of the slag irrigation is made of northeast pine wood, and the molding material is furan resin sand. The proportion of each addition is furan resin: curing agent: sand = 1.3:0.78:100, and the tensile strength of the resin san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com