Gas spring device for warp knitting machine

A gas spring and warp knitting machine technology, which is applied in the field of warp knitting machines, can solve the problems of inaccurate guidance, easy damage, and large wear of guide holes, and achieve the effects of avoiding interference, simplifying difficulty, and improving traversing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

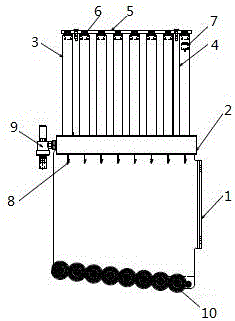

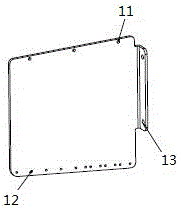

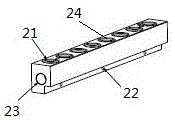

[0020] Such as figure 1 It is a structural diagram of the present invention, a gas spring device for warp knitting machines, including angle iron support 1, gas spring support 2, gas spring column 3, support column 4, gas spring column support plate 5, sleeve 6, piston 7. Drag hook 8, muffler 9 and guide wheel combination 10, the upper end of angle iron support 1 is provided with round hole one 11, the lower end of angle iron support 1 is provided with round hole two 12, and the right side of angle iron support 1 is provided with round hole one. Hole three 13, the middle of the upper surface of the gas spring support 2 is provided with a round hole four 21, the two ends of the upper surface of the gas spring support 2 are provided with threaded holes 2 24, and the side of the gas spring support 2 is provided with a horizontal hole 23 The bottom of the gas spring support 2 is provided with a horizontal threaded hole 22, the gas spring support 2 is fixed above the angle iron sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com