A kind of preparation method of cellulose composite filter element material for engine air filter

A composite filter element and engine technology, which is used in fiber raw material processing, natural cellulose pulp/paper, paper machines, etc., can solve the problems of composite filter element materials for engine air filtration, etc., which can improve reliability and service life. The effect of reducing production costs and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Beat pine wood pulp and poplar wood pulp to 25SR° and 30SR°, respectively, with a beating concentration of 1%, to obtain beaten pine wood pulp and poplar wood pulp;

[0024] 2) Make the beaten pine pulp obtained in step 1) into a basis weight of 50g / m 2 The upper filter element material;

[0025] 3) The beaten pine wood pulp and the beaten poplar wood pulp obtained in step 1) are combined with a mass ratio of 3:7 to make a basis weight of 50g / m 2 The lower filter element material;

[0026] 4) Using an interlayer wet composite process, the upper filter element material obtained in step 2) and the lower filter element material obtained in step 3) are pressed and combined to form a composite filter element material in a wet state;

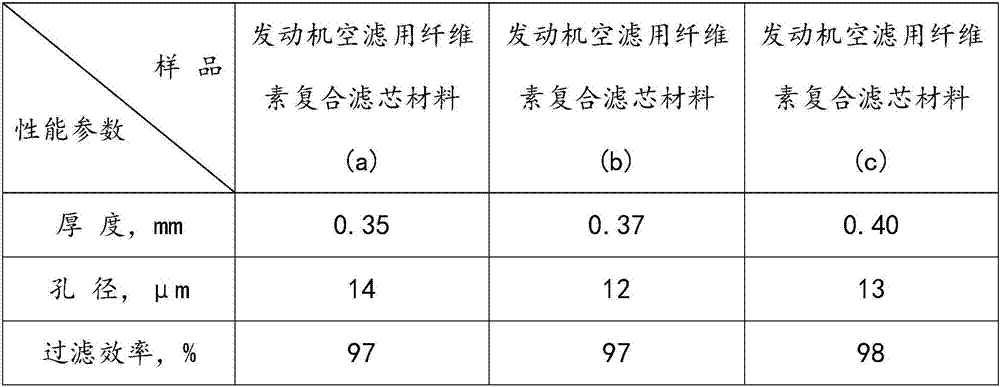

[0027] 5) Dry the composite filter element material in the wet state obtained in step 4) at a temperature of 104°C and a vacuum of 0.8 MPa for 20 minutes to obtain a cellulose composite filter element material for engine air filtration with a pore si...

Embodiment 2

[0029] 1) Beat the pine wood pulp and eucalyptus pulp to 27SR° and 28SR°, respectively, with a beating concentration of 1.5%, to obtain beaten pine wood pulp and poplar wood pulp;

[0030] 2) Make the beaten pine pulp obtained in step 1) into a basis weight of 50g / m 2 The upper filter element material;

[0031] 3) The beaten pine pulp and the beaten eucalyptus pulp obtained in step 1) are combined with a mass ratio of 5:5 to make a basis weight of 50g / m 2 The lower filter element material;

[0032] 4) Using an interlayer wet composite process, the upper filter element material obtained in step 2) and the lower filter element material obtained in step 3) are pressed and combined to form a composite filter element material in a wet state;

[0033] 5) Dry the composite filter element material in the wet state obtained in step 4) for 15 minutes at a temperature of 105°C and a vacuum of 0.9 MPa to obtain a cellulose composite filter element material for engine air filtration with a pore siz...

Embodiment 3

[0035] 1) Beat the pine wood pulp and acacia pulp to 30SR° and 25SR°, respectively, with a beating concentration of 2%, to obtain beaten pine wood pulp and acacia pulp;

[0036] 2) Make the beaten pine pulp obtained in step 1) into a basis weight of 50g / m 2 The upper filter element material;

[0037] 3) Combine the beaten pine wood pulp and beaten acacia pulp obtained in step 1) at a mass ratio of 7:3 to make the basis weight 50g / m 2 The lower filter element material;

[0038] 4) Using an interlayer wet composite process, the upper filter element material obtained in step 2) and the lower filter element material obtained in step 3) are pressed and combined to form a composite filter element material in a wet state;

[0039] 5) Dry the composite filter element material in the wet state obtained in step 4) for 10 minutes at a temperature of 106°C and a vacuum of 1 MPa to obtain a cellulose composite filter element material for engine air filtration with a pore size of 13 μm (c ).

[0040...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com