Concrete-filled steel tubular column with defect recognition function

A technology for steel pipe concrete columns and reinforced concrete columns, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of ineffective classification of test results, inaccurate test results, and insufficient depth of information mining, etc., and achieve high construction efficiency and high construction efficiency. The effect of short cycle time and low engineering difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described with reference to the following examples.

[0015] Application Scenario 1

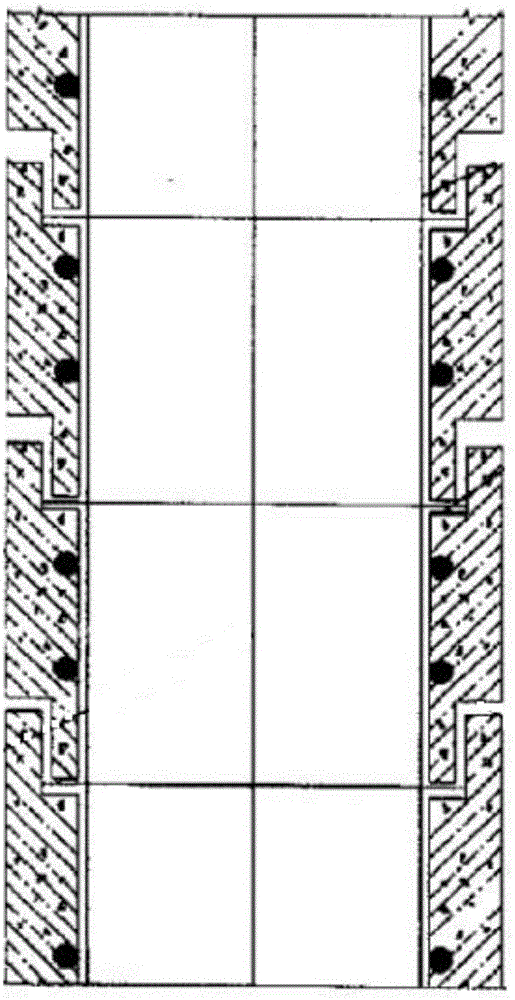

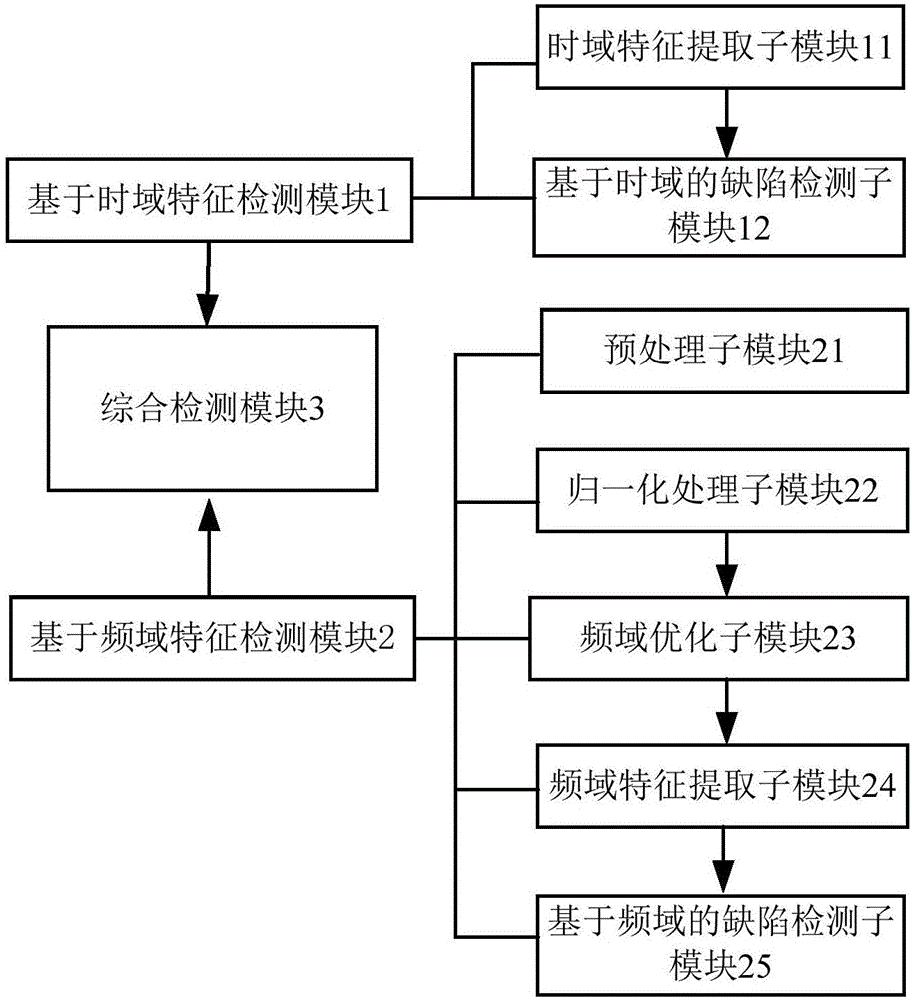

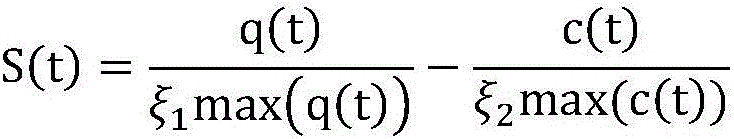

[0016] see figure 1 , figure 2 , A concrete-filled steel tubular column with a defect identification function of the present embodiment includes a reinforced concrete column and a non-destructive testing device connected to the reinforced concrete column. The reinforced concrete column includes a reinforced concrete prefabricated member and a steel bar, and is characterized in that the steel bar is: The concrete column is composed of a plurality of reinforced concrete cylindrical prefabricated components, longitudinal steel bar positioning meshes, and longitudinal steel bars. Multiple reinforced concrete cylindrical prefabricated components are superimposed to form a column form, and the joints between the adjacent reinforced concrete cylindrical prefabricated components are set. Longitudinal steel bar positioning mesh adapted to the inner cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com