Concrete paving equipment with curved surface paving function

A concrete and curved surface technology, which is applied in the processing of building materials, construction, and building construction, can solve problems such as low construction efficiency, slow speed, and unfavorable health of workers, so as to reduce labor intensity, speed up construction progress, and improve production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

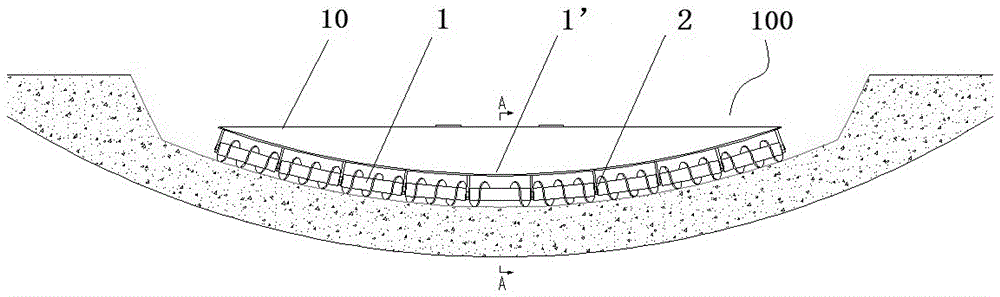

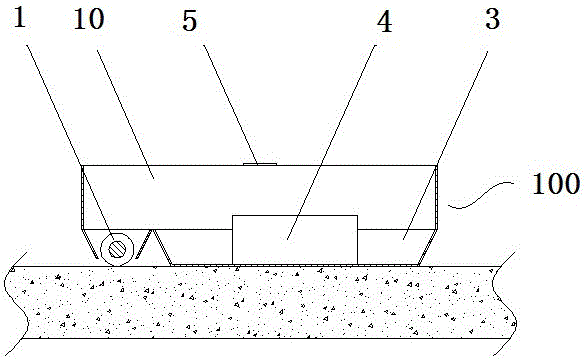

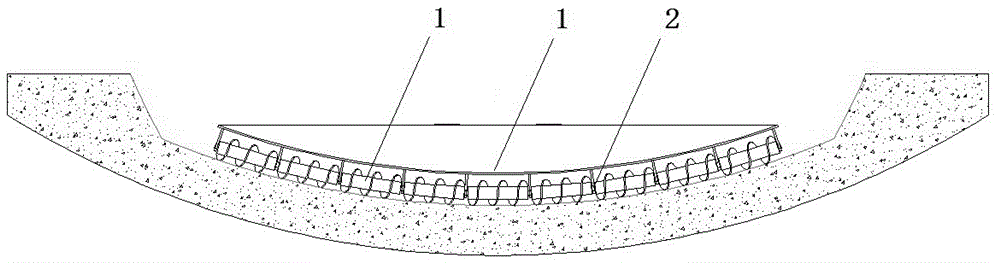

[0030] Attached below Figures 1 to 11 The present invention is further described, but the implementation of the self-propelled mobile trestle is not limited thereto, and replacements within the common knowledge of those skilled in the art should be included in the scope of protection.

[0031] The present invention includes a curved surface adjustable paving mechanism 100, which can be adjusted automatically according to the radian of the construction curved surface, so that the working surface of the paving mechanism and the construction surface fit together.

[0032] The curved surface adjustable paving mechanism 100 is mainly composed of at least two screw conveyors 1 arranged between the frames 10, the screw conveyors 1 are connected by a universal coupling 2; the working surface of the screw conveyor 1 is The broken line section forms a curved surface that fits the construction surface, and the width of the screw conveyor 1 should meet the construction width of the tunne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com