Porcelain door leaf

A door leaf and ceramic coating technology, applied in the door leaf field, can solve the problems of difficulty in effectively blocking the diffusion of toxic smoke, the door panel is not refractory, and the cost is high, and achieves the effects of high strength, good waterproofness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

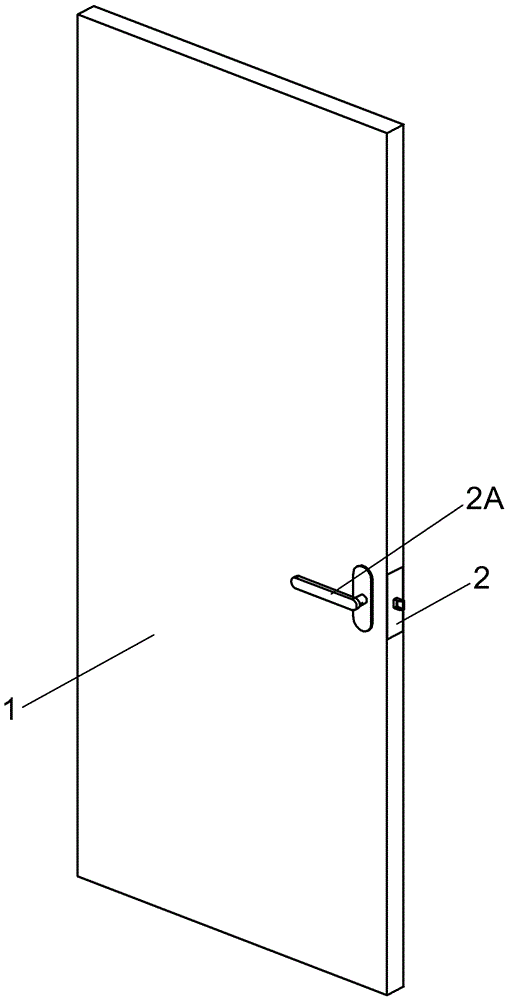

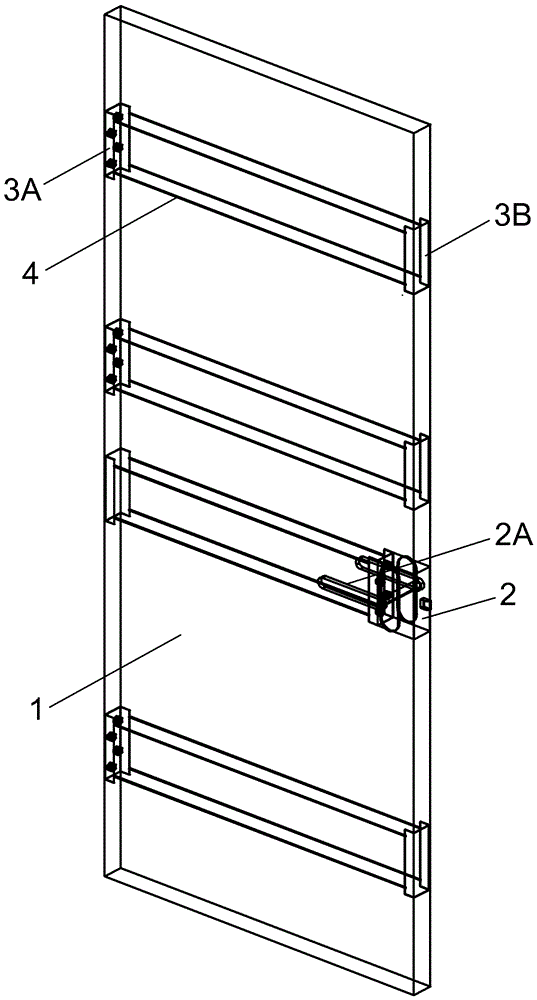

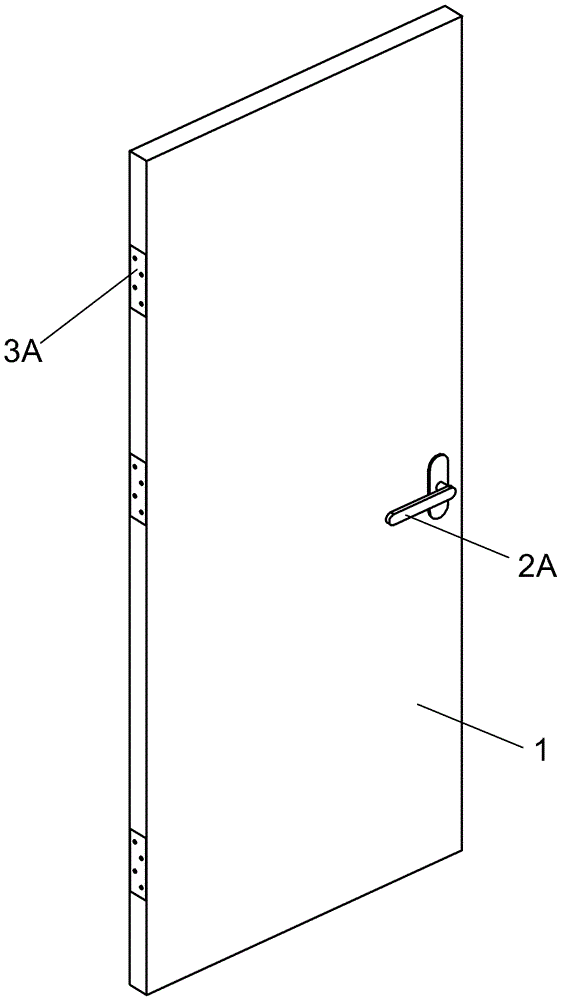

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 , the porcelain door leaf of the present invention is provided with a door lock (2) and a door handle (2A), and a plurality of structural parts (3A, 3B) are also arranged in the door leaf, and the structural parts (3A, 3B) are separately pre-embedded on the edge of the door leaf And the position where the lock is installed, and each structural part (3A, 3B) is connected and tightened with the other relative structural parts through the steel wire (4), for example, the structural part 3A shown in the figure is connected to the opposite other structural part through the steel wire (4) The structural parts 3B on one side are connected, so that the pre-embedded structural parts (3A, 3B) are firmly fixed on the door leaf body (1). In addition, screw holes corresponding to the screw holes on the hinge are preset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com