Drilling mud splash joint

A technology for anti-splash joints and drilling mud, which is applied to drilling equipment, drill pipes, drill pipes, etc., can solve the problems of incomplete prevention of mud leakage, high cost of installing plug valves, and single structure, and achieves reasonable and reliable structure and low cost. Low, well-conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

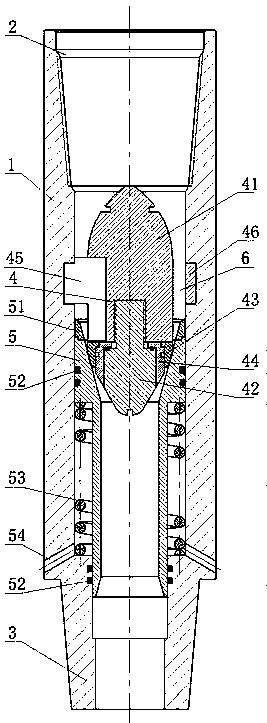

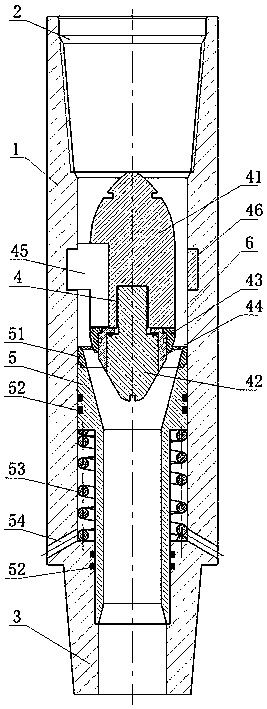

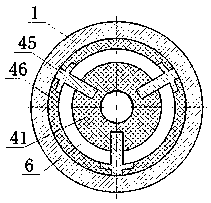

[0031] Drilling mud splash joint of the present invention, its structure is as figure 1 As shown, it includes a tubular body 1, one end of the body 1 is a kelly connection end 2, and the other end is a drill pipe connection end 3, the inner cavity of the body 1 is fixedly provided with a sealing core 4, and the outer diameter of the sealing core 4 is less than The inner diameter of the main body 1 forms an annular cavity 6 for the passage of mud. The inner cavity of the main body 1 is also provided with a bidirectionally movable sealing seat ring 5, which is located between the sealing core 4 and the connecting end 3 of the drill pipe. Section, and the sealing seat ring 5 is assembled in the body 1 through the elastic member, and is fitted between the inner cavity of the main body 1 and the sealing core 4 through the elastic force of the elastic member to form a seal, so as to realize the closure of the joint. When the sealing seat ring 5 When receiving the mud pressure from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com