Four-way ball valve

A ball valve and channel technology, applied in the field of four-way ball valves, can solve the problems of poor valve sealing reliability, large cavity size in the valve body, and many leakage factors, so as to improve sealing reliability, reduce overall weight, and ensure normal use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

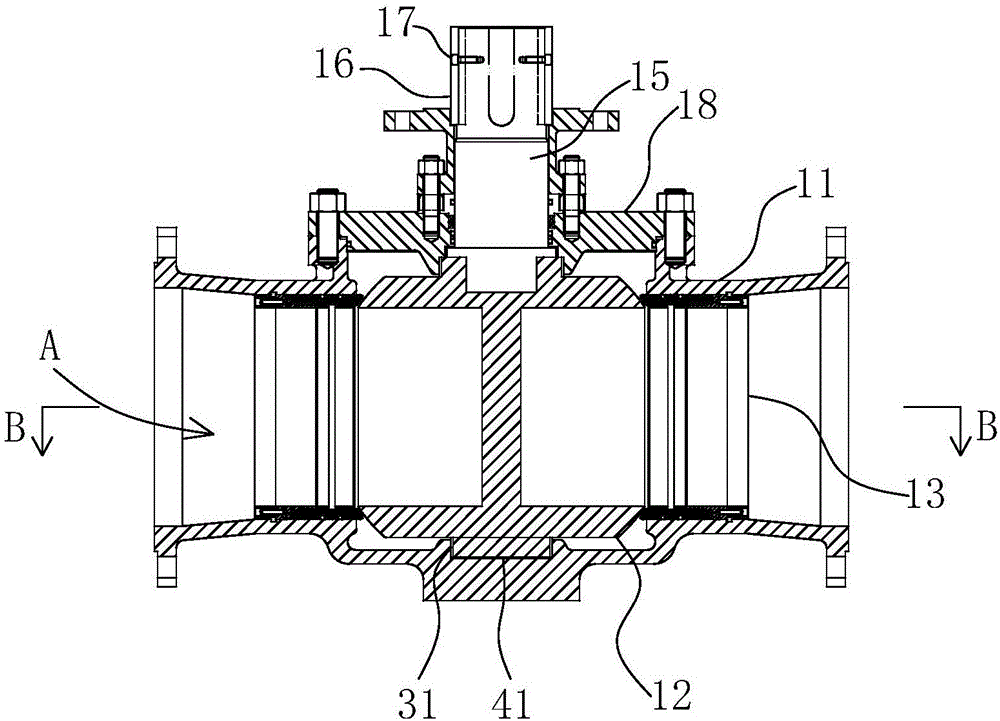

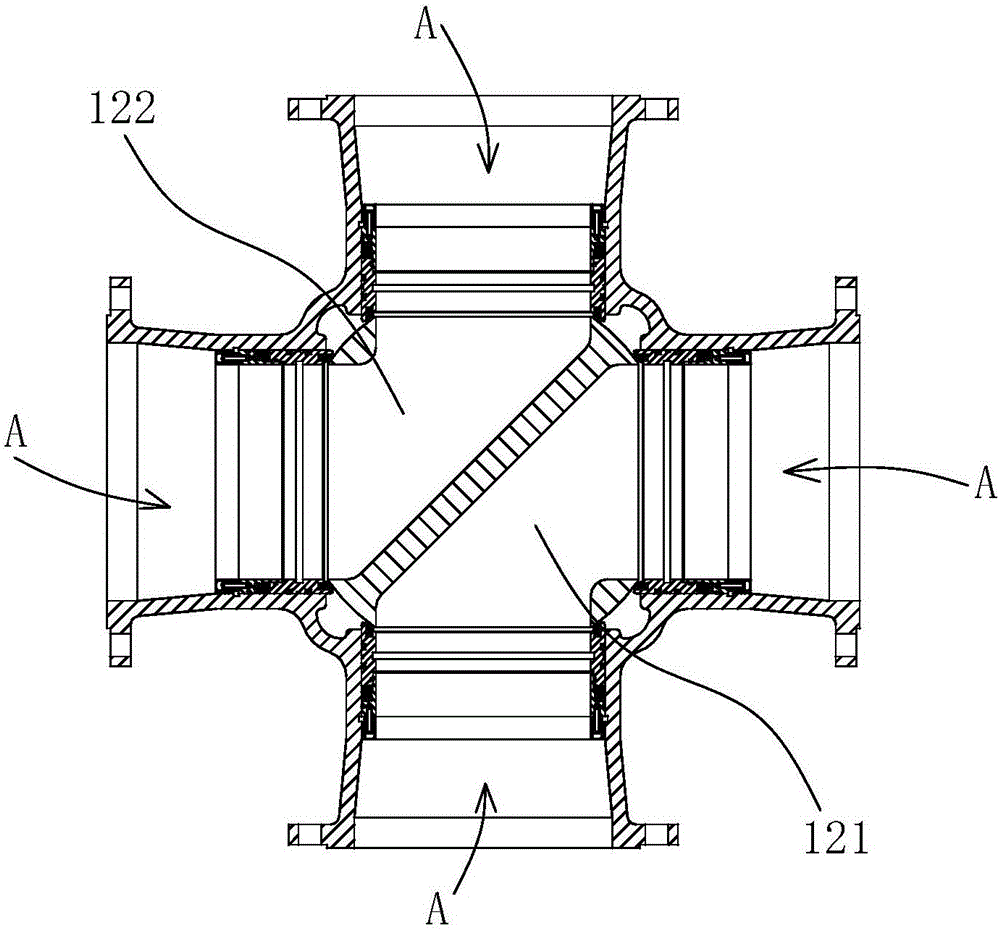

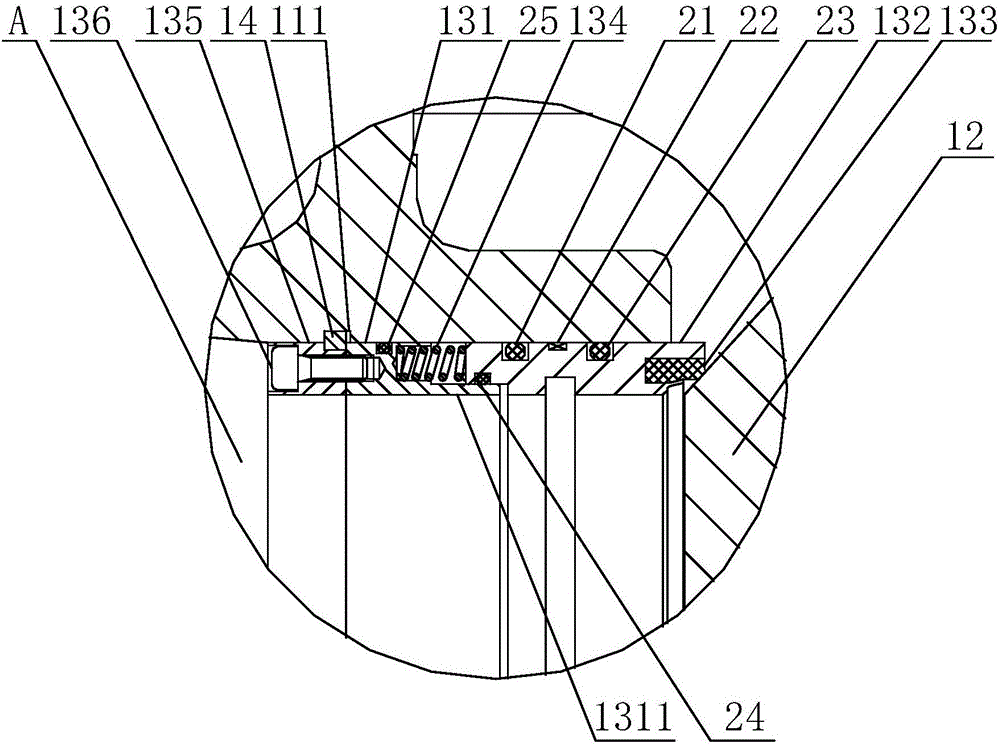

[0040] Below in conjunction with accompanying drawing, technical solution of the present invention is described:

[0041]The present invention includes a valve body 11 containing four fluid inlet and outlet passages A and a valve core 12 located in the inner chamber of the valve body and used to switch the flow direction of the fluid. A valve seat assembly is arranged in the fluid inlet and outlet passages A, and the valve The seat assembly includes a preloaded spring pressure ring 131 coaxial with the fluid inlet and outlet channel A and sequentially arranged along the axis, a valve seat support cylinder 132 and an annular valve seat sealing ring 133 that forms a sealing fit with the valve core 12 , the outer surface of the valve seat support cylinder 132 is in sealing fit with the inner wall surface of the fluid inlet and outlet channel A, and the end surface of the valve seat support cylinder 14 close to the inner cavity of the valve body is provided with a ring groove for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com