A limit device for high-temperature reheat steam pipeline and its arrangement method

A steam pipeline, high-temperature reheating technology, applied in pipeline systems, pipeline supports, pipes/pipe joints/pipe fittings, etc., can solve the problems that the support and hanger structure cannot be generalized, the overall structure is unreasonable, and the investment cost is high. The effect of reducing the difficulty of distributed computing, wide application and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

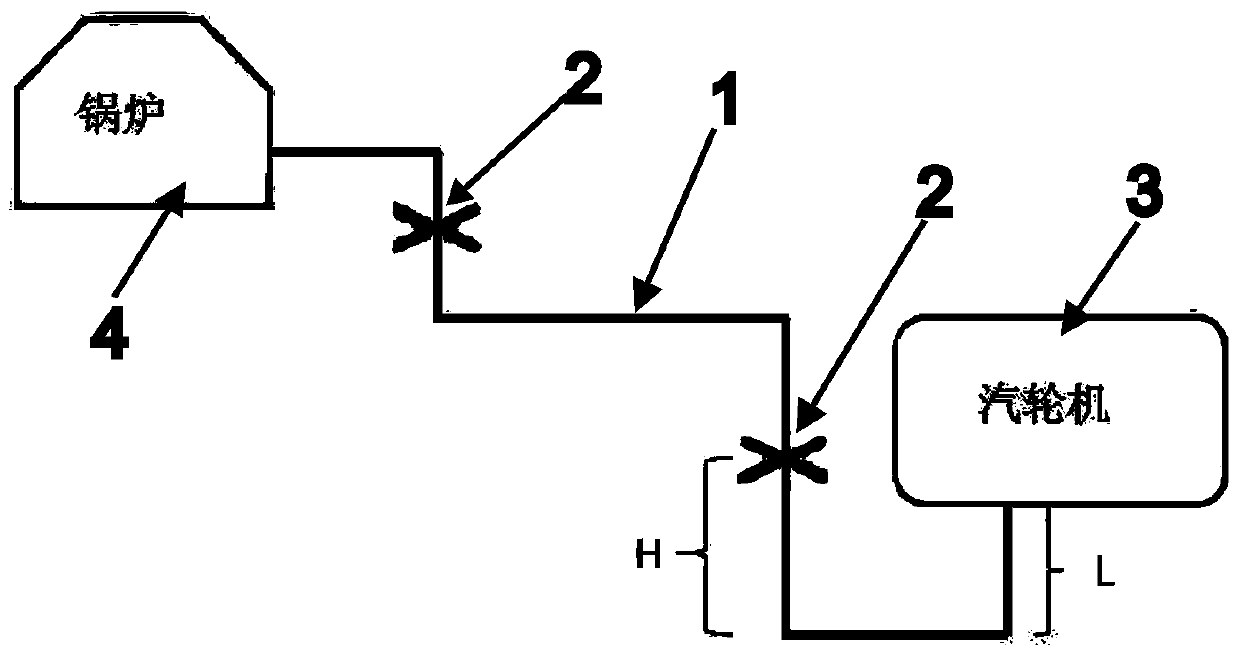

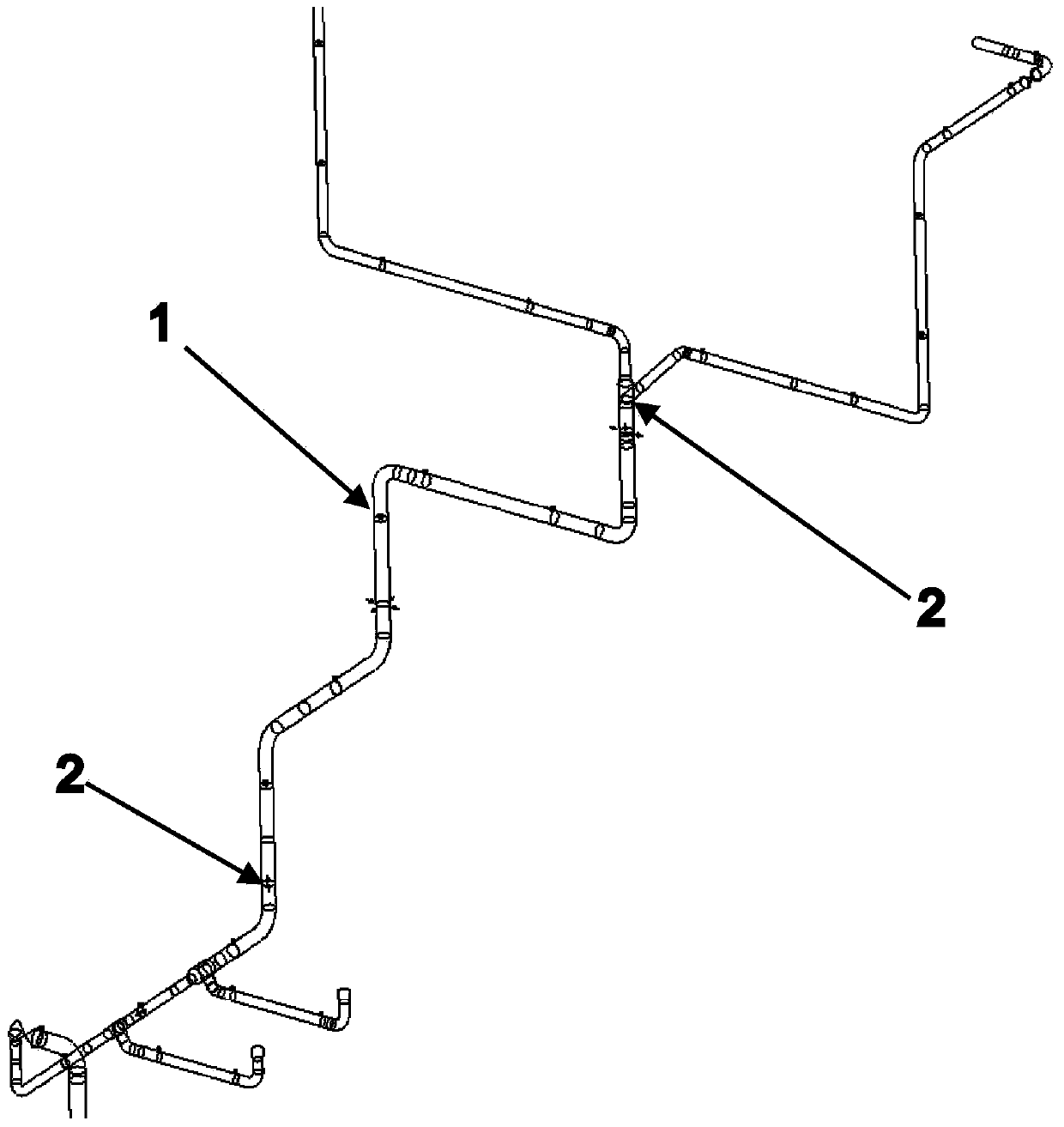

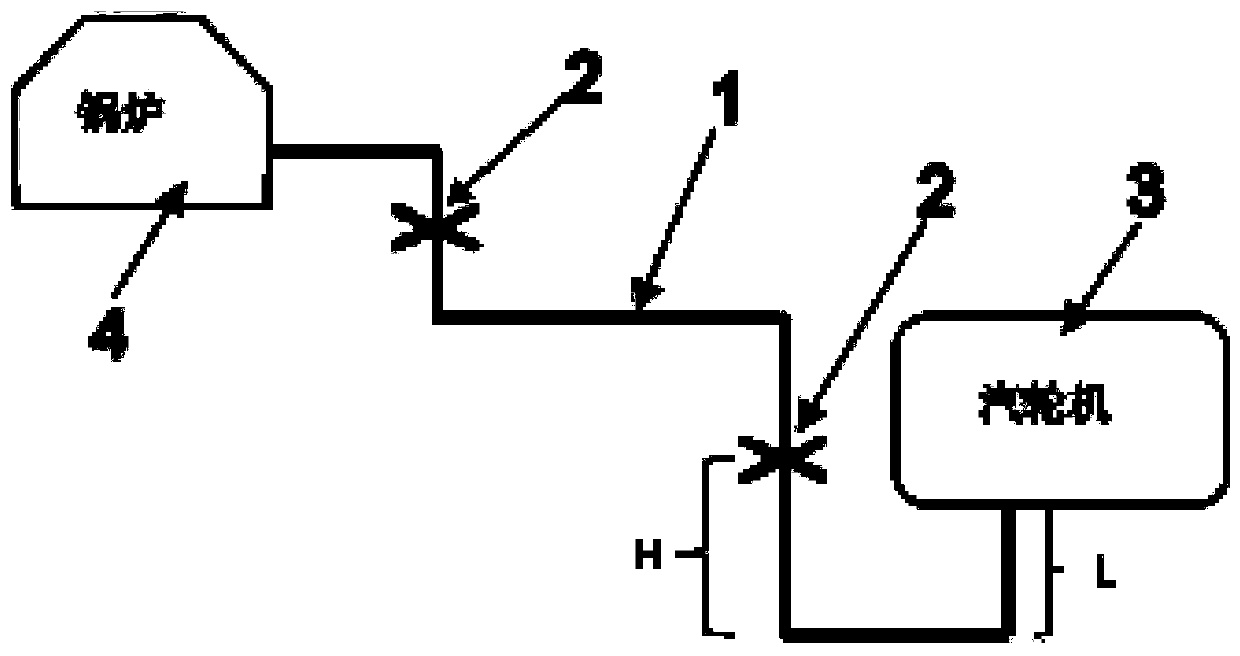

[0029] Reference figure 1 with figure 2 , This embodiment relates to a high-temperature reheat steam pipe limiting device, including a high-temperature reheat steam pipe 1 and equipment connected to the two ends of the high-temperature reheat steam pipe. A number of axial directions are provided on the high-temperature reheat steam pipe 1. The stopper 2 uses the thermal expansion characteristics of the pipeline itself to offset the thermal displacement of the equipment interface. The axial stopper 2 is arranged near the connection between the high-temperature reheat steam pipeline 1 and the equipment to reduce the high-temperature reheat steam pipeline system The overall thrust and thrust distance generated by the device interface; the number of axial stoppers 2 is the same as the number of interfaces connected to the high-temperature reheat steam pipe 1, which is 1-5; the setting position of the axial stopper 2 is determined by The expression H=Z / (T×α)+L is determined. In the...

specific Embodiment 2

[0060] The specific embodiment 2 of the present invention is characterized in that the axial stopper 2 is an axial reinforcement provided on the high-temperature reheat steam pipe 1 to limit the axial expansion and contraction of the high-temperature reheat steam pipe 1. The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com