Environment-friendly dense and sparse burner

A thick-lean combustion, environmentally friendly technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as poor combustion stability, increase the concentration of comprehensive pollutants, and insufficient flame combustion, achieve good stability, reduce The effect of the combined pollutant concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

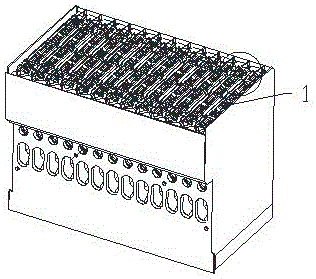

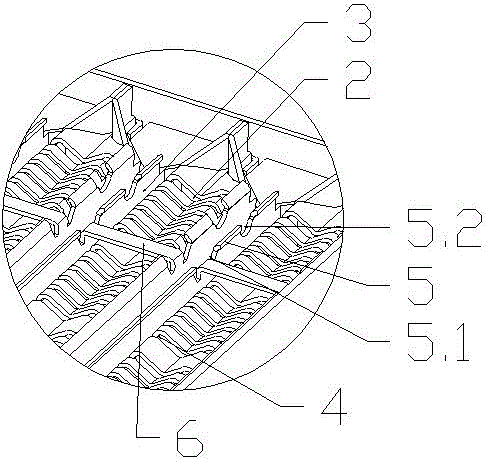

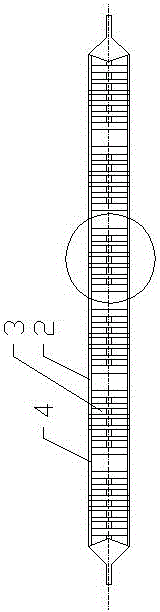

[0037] see Figure 1-10 , the present invention relates to an environment-friendly rich-lean burner, which includes several fire rows 1 arranged in parallel at intervals, and several groups of thin flame hole groups are distributed in parallel on each fire row 1, and each group of thin flame hole groups includes A plurality of thin flame holes 2 are arranged in parallel, through which gas burns to form a thin flame 8 .

[0038] The fire row 1 also includes a flame hole side plate 4 and a fire row side plate 5, the fire row side plate 5 is arranged outside the flame hole side plate 4, the two form a thick flame hole 3, and the gas passes through the thick flame hole 3 Combustion forms thick flame 9, and each group of thin flame hole group is positioned at middle thin light hole 2 narrow, is positioned at both sides thin light hole 2 wide, and the narrow thin light hole 2 length in the middle extends to the outside of flame hole side plate 4 top, light There is more oxygen in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com