Compact water level sensor

A water level sensor, compact technology, applied in the direction of displaying liquid level indicators, washing devices, and other washing machines through pressure measurement, which can solve the problem of inability to achieve precise control of water level, non-vertical water level spring, and inability to ensure that the magnetic core moves upward in a straight line, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

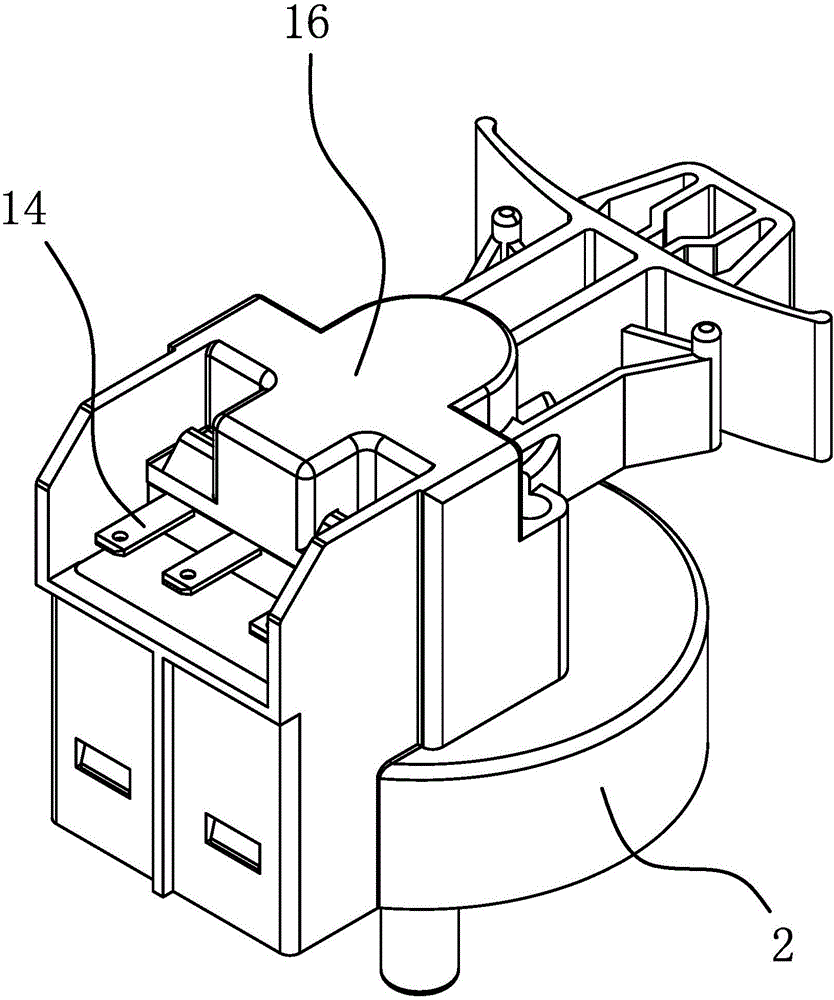

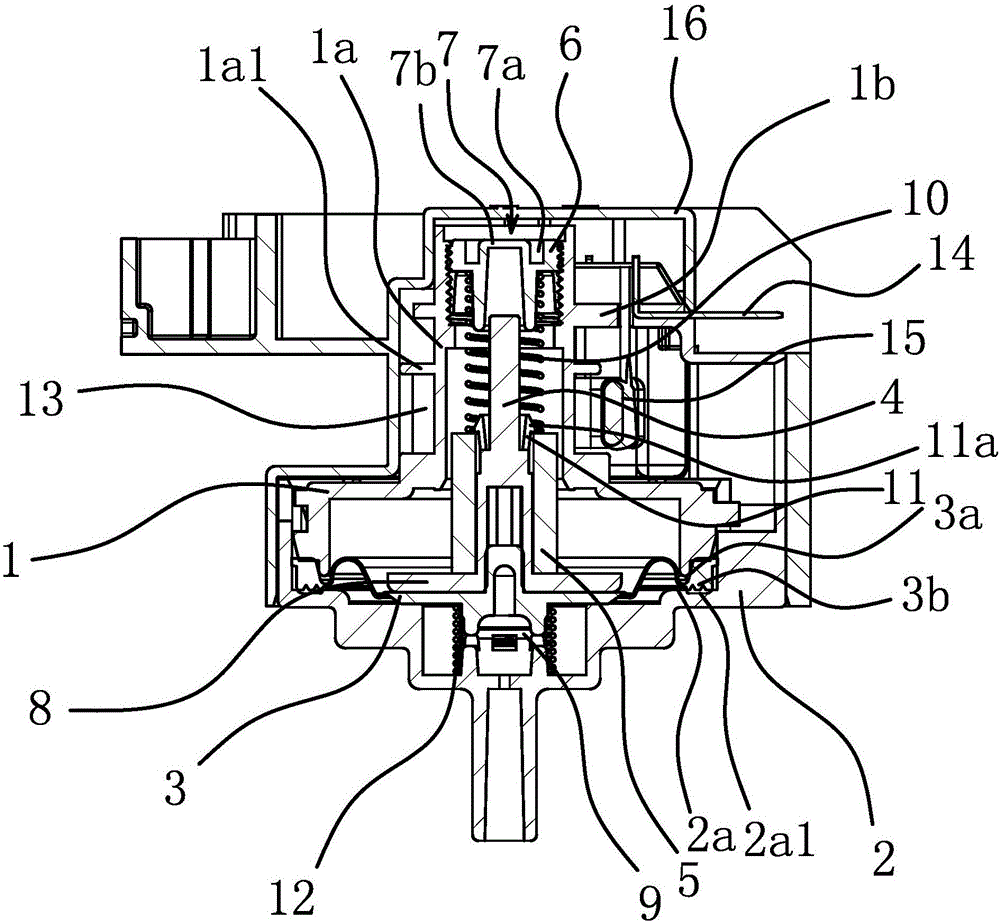

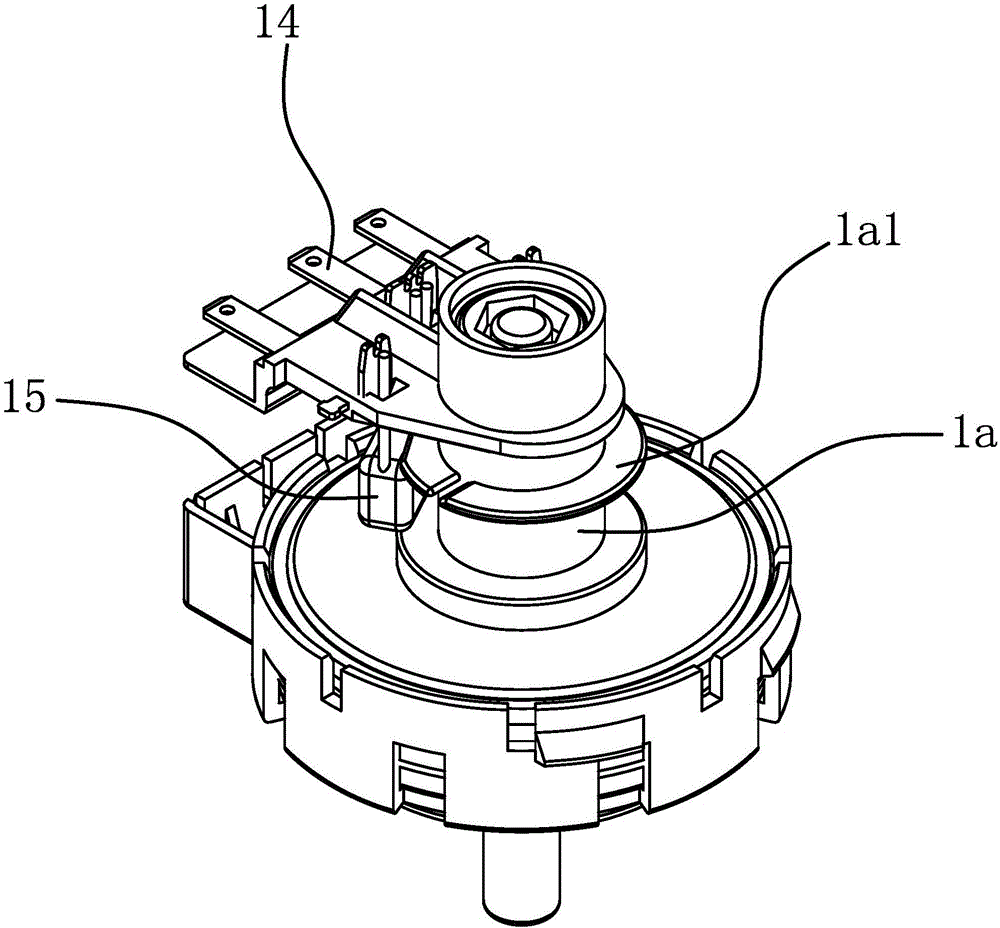

[0086] Such as figure 1 and figure 2 and image 3 and Figure 4 As shown, the compact water level sensor includes a housing, a sealing film 3, a guide rod 4, an LC oscillating circuit mechanism, and a magnetic core 5. The interior of the housing is a cavity, and the sealing film 3 is connected to the housing and connects the housing Separated into two chambers adjacent up and down: the upper chamber and the lower chamber, the above-mentioned LC oscillation circuit mechanism is fixedly connected to the upper part of the housing, the lower end of the above-mentioned guide rod 4 is fixedly connected with the sealing film 3, and the upper end of the guide rod 4 The above-mentioned magnetic core 5 is fixedly connected to the guide rod 4. When the sealing film 3 acts on the pressure of the fluid medium, the guide rod 4 will move up and down with the sealing film 3. The above-mentioned magnetic core 5 will move up and down with the guide rod. 4. After synchronous movement, the na...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap