Boundary slip test device with controllable slip ratio

A test device, the technology of the slip-roll ratio, applied in the direction of measurement device, surface/boundary effect, instrument, etc., can solve the problems of affecting promotion, expensive equipment, and single working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the accompanying drawings and examples.

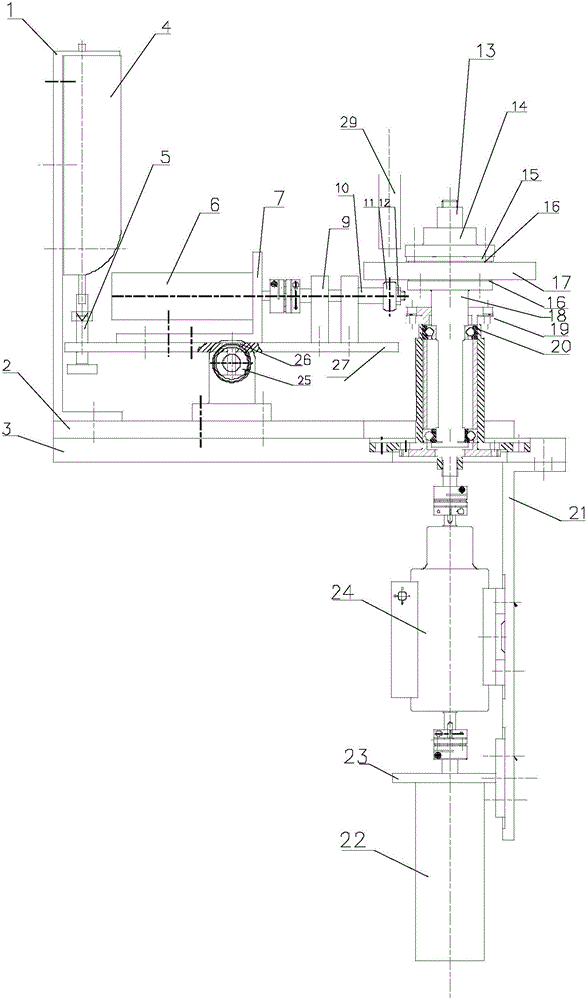

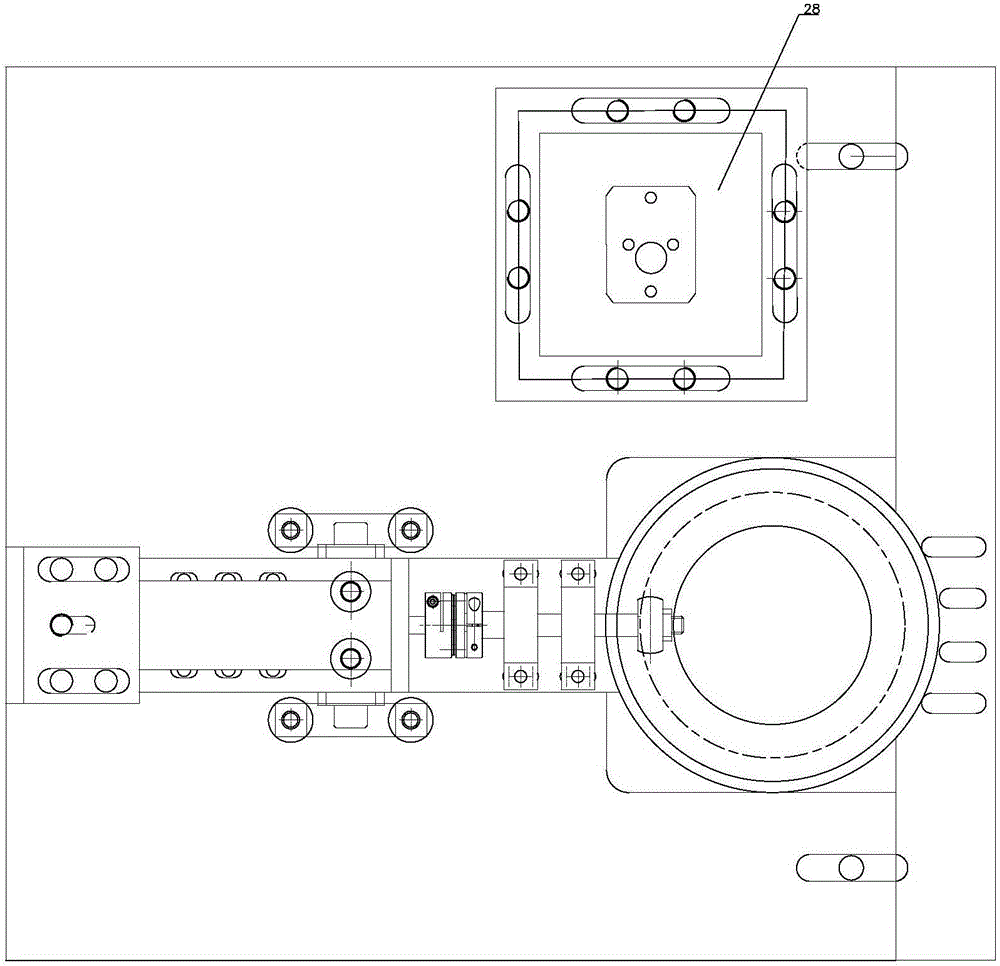

[0014] See attached figure 1 , a boundary slip test device with controllable slip-to-roll ratio, the test device includes four parts: friction pair kinematic system, loading system, microscope observation system and support system.

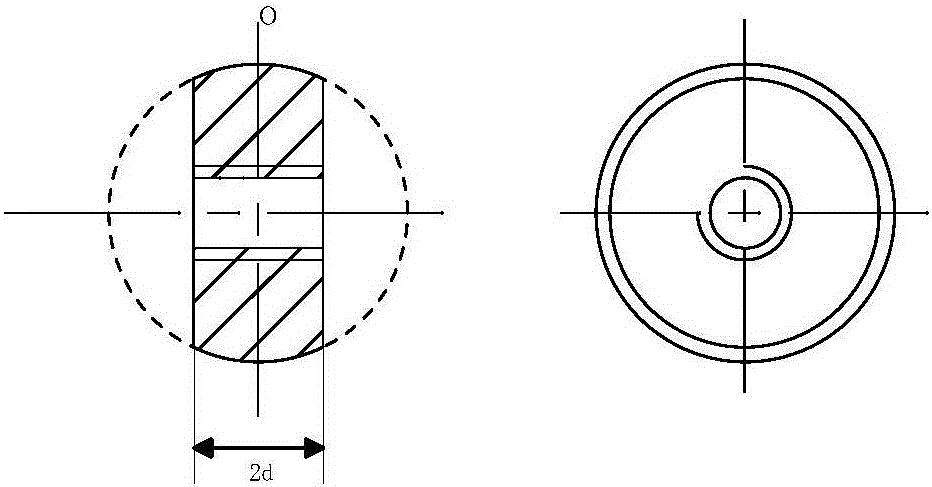

[0015] See attached figure 2 , the friction pair motion system is further divided into a first friction element motion control assembly and a second friction element motion control assembly. The motion control assembly of the first friction element includes: a first motor 6 , a shaft coupling, a ball bat 10 , a first friction element 11 and a first fixing nut 12 . The first friction element 11 is installed at one end of the ball bat 10, fixed and positioned by the first fixing nut 12; the first motor 6 is connected to the other end of the ball bat 10 through a coupling, thereby controlling the movement of the first friction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com