On-line detection method of laser welding penetration

A technology of laser welding and detection method, which is applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problem that the welding penetration characteristic information is difficult to effectively separate, the time domain and frequency domain changes are complex, and the amount of mixed information is large, etc. problem, to achieve the effect of qualitative and quantitative identification, difficulty reduction, and reliable characteristic parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An on-line detection method of laser welding penetration, according to the special state characteristics of laser welding penetration changes, through conventional optical mixed signals, sequentially adopt special spectral band signal separation, specific welding area signal separation, and welding defect probability distribution characteristic signal separation Three processing methods can effectively remove the severe interference in the mixed signal, simplify and separate the reliable welding penetration characteristic information layer by layer, and solve the problem of large amount of mixed information in the detection signal, complex changes in time domain and frequency domain during laser welding. Accurate online identification of laser welding penetration is achieved due to the technical problems of severe signal fluctuations and difficulty in effectively separating welding penetration characteristic information;

[0029] The method for separating signals in spec...

Embodiment 2

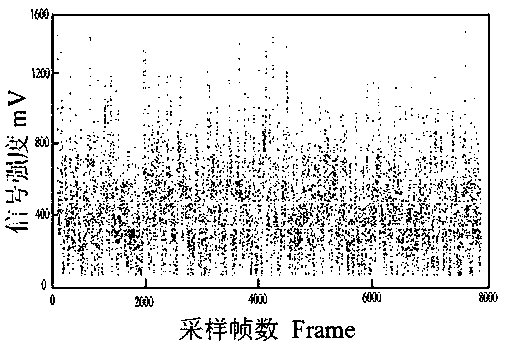

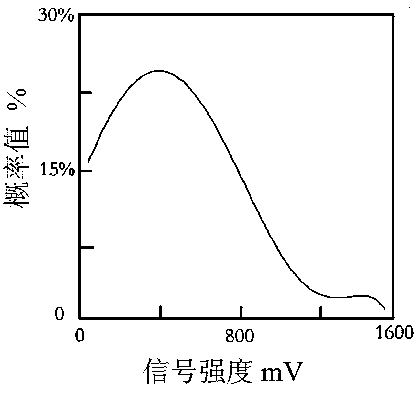

[0033] According to the online detection method of laser welding penetration described in Example 1, a 10mm thick carbon steel plate was selected as the welding object, and two 7.5mm deep rectangular grooves were machined on the back of the steel plate before welding, and the experimental plate was subjected to 3000W laser power. Surface surfacing, the test plate without the groove is the in-penetration weld, and the rectangular groove is the complete penetration weld, and the welding penetration detection method of this product is used, and the detection results are as attached image 3 , 4 As shown in the comparison, it is found that the intensity value of the optical detection signal obtained by the "specific welding area signal separation method" is significantly higher under the incomplete penetration weld than that under the complete penetration weld. Figure 5 It is the detection result processed by the "welding defect probability distribution characteristic signal sepa...

Embodiment 3

[0035] According to the online detection method of laser welding penetration described in Example 1, a 10mm thick carbon steel plate is selected as the welding object, and two 7.5mm deep rectangular grooves are also machined on the back of the steel plate before welding, and 2000W laser power is used to test the test plate Carry out surfacing welding, what obtain at the no-groove place of experimental plate is not penetration weld seam, and what obtain at rectangular groove place is a small amount of penetration weld seam, adopt the detection result of the present invention method as follows Image 6 , 7 , 8, by attaching Figure 7 and Figure 4 It can be seen from the comparison that the overall intensity of the optical detection signal of a small amount of penetration experiment is significantly lower than that of complete penetration, and the intensity difference between the penetration and non-penetration optical detection signals is obviously weakened, but through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com