Method for detecting internal structure of cement graded crushed stones for high-speed rail roadbed

A technology for grading crushed stones and internal structures, applied in the direction of measuring devices, preparation of test samples, material analysis using radiation, etc., can solve problems such as poor precision and large error range, and achieve novel methods, strong practicability, 3D reconstruction effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

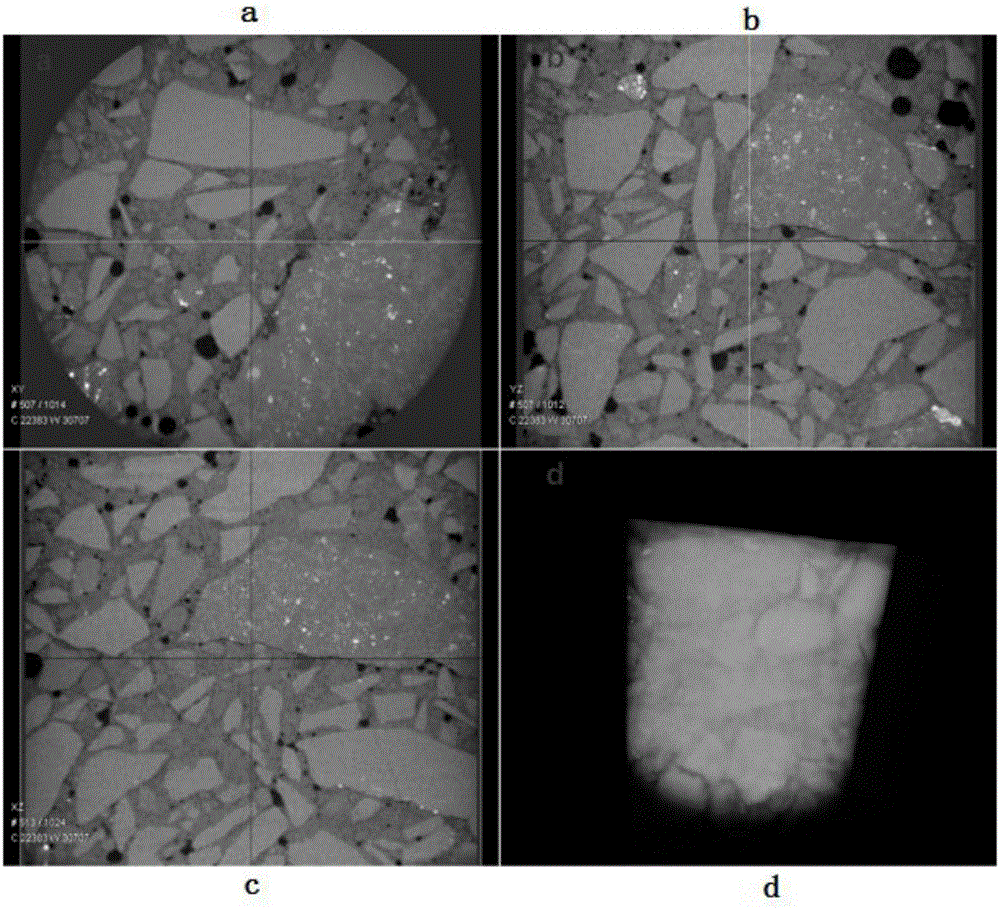

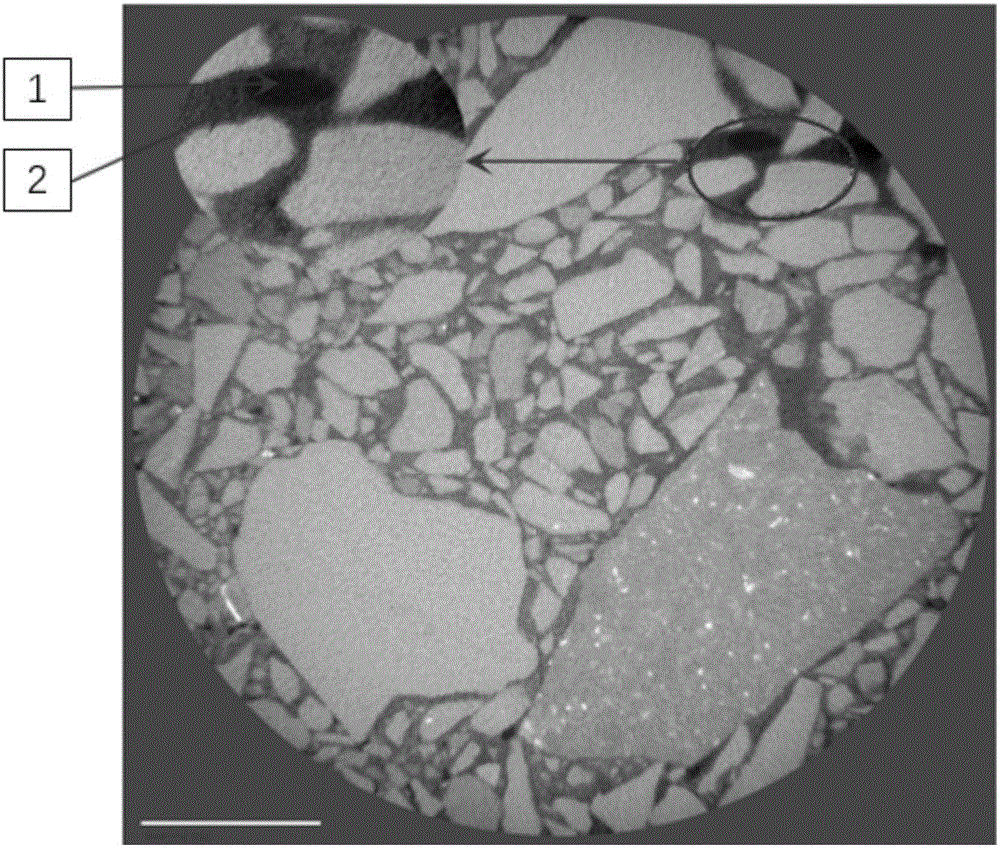

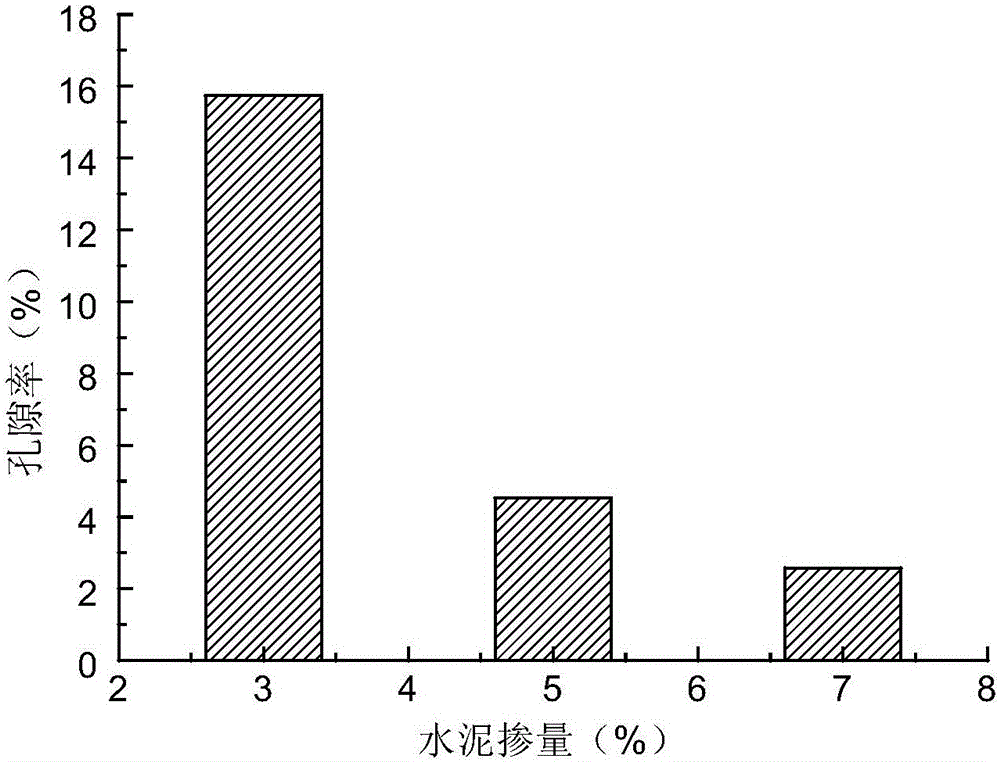

Embodiment 1

[0036] Weigh the raw materials according to the mass fraction, take 90% graded crushed stone, 5% cement, 1:1 water-cement ratio (water 5%), fully mix and pour into a 100×100×100mm cube sample, and the curing temperature is 20± 2℃, curing humidity above 90%, curing for 28 days. A cylinder with a size of φ48×57mm is used as the scanning sample. The experimental result is that the porosity of cement graded crushed stone is 4.53%.

Embodiment 2

[0038] Weigh the raw materials according to the mass fraction, take 86% graded crushed stone, 7% cement, 1:1 water-cement ratio (water 7%), mix thoroughly and pour into a 100×100×100mm cube sample. The curing temperature is 20± 2℃, curing humidity above 90%, curing for 28 days. A cylinder with a size of φ48×57mm is used as the scanning sample. The experimental result is that the porosity of cement graded crushed stone is 2.58%.

Embodiment 3

[0040] Weigh the raw materials according to the mass fraction, take 94% graded crushed stone, 3% cement, 1:1 water-cement ratio (water 3%), mix thoroughly and pour into a 100×100×100mm cube sample. The curing temperature is 20± 2℃, curing humidity above 90%, curing for 28 days. A cylinder with a size of φ48×57mm is used as the scanning sample. The experimental result is that the porosity of cement graded crushed stone is 15.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com