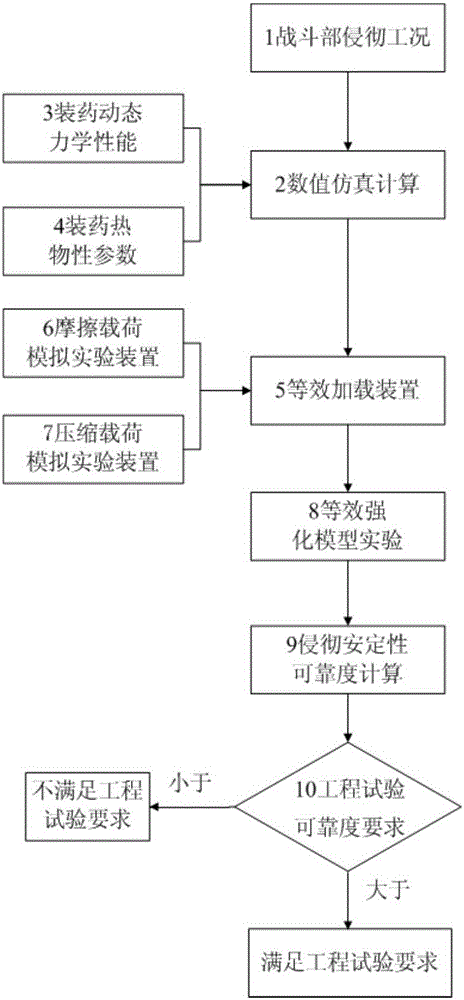

Explosive loading and penetrating stability evaluation method based on equivalent model experiment

A technology of equivalent model and model experiment, applied in the direction of measuring device, using mechanical device, using stable tension/pressure to test the strength of materials, etc., can solve the problem of high research cost, non-equivalent explosive charge and long cycle. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

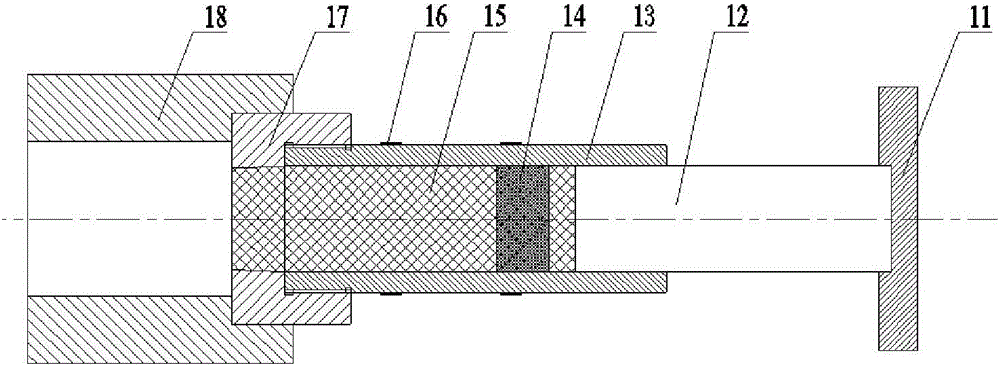

[0064] In this embodiment, the warhead filled with high-energy explosives penetrates a 6-meter-thick reinforced concrete target at a speed of 900 m / s.

[0065] Step 1: Acquisition of dynamic mechanical properties and thermophysical properties of explosive charges

[0066] The explosive charge was tested at a strain rate of 3200s using a separate Hopkinson pressure bar -1 , 3700s -1 The dynamic mechanical performance parameters at 4300 and 4300, the stresses are 25.6MPa, 28MPa and 30MPa respectively, and the strains are 1.9%, 2.4% and 2.8%, respectively.

[0067] According to the method 405.1, method 408.2 and method 409.2 in GJB772A-97, the specific heat capacity, linear expansion coefficient and thermal conductivity of the explosive charge are respectively: 1.327J / g / ℃, 9.1(10 -5 K -1 ) and 1.21W / (m·K).

[0068] Step 2: Determine the maximum compressive load and friction load experienced by the explosive charge penetration process

[0069] Using the commercial software LS...

Embodiment 2

[0078] In this embodiment, a 500kg-class warhead loaded with high-energy explosive penetrates a 30mm thick steel target at a speed of 700m / s. The device and steps used for evaluating the penetration stability of the explosive charge are the same as in Embodiment 1.

[0079] Explosive charges at a strain rate of 3000s -1 、3500s -1 The dynamic mechanical performance parameters at 4100 and 4100, the stresses are 28.6MPa, 35MPa and 41MPa respectively, and the strains are 1.9%, 1.8% and 1.6%, respectively. The specific heat capacity, linear expansion coefficient and thermal conductivity of the explosive charge are: 1.245J / g / ℃, 8.2(10 -5 K -1 ) and 0.77W / (m·K).

[0080]The LS-DYNA calculation results show that the maximum compressive stress on the explosive charge is 800MPa, the stress rise time is about 40us, that is, the stress rate is 20MPa / us, and the maximum frictional power density is 3.2×10 7 w / m 2 .

[0081] In the equivalent strengthening model test, strengthening exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com