Steel member delivery progress detection system based on BIM technology

A detection system and steel component technology, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of vacant labor and mechanical resources, reduce the vacancy of resources and waste of funds, reduce the occupation of factory working capital, and realize informatization management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment example the present invention is further described:

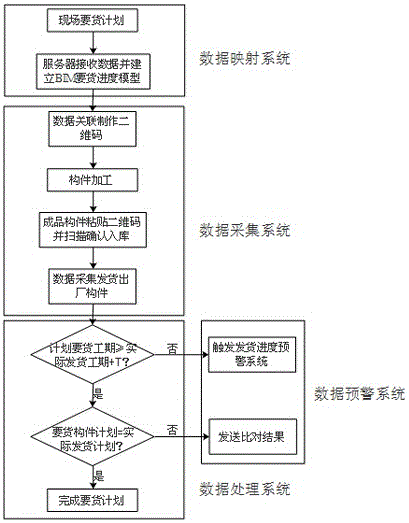

[0027] A BIM technology-based delivery detection method for steel components, which includes the following steps:

[0028] (1) A device to obtain a series of basic attributes such as the name, unique number, length, specification, material, and construction period of all steel components planned to be purchased;

[0029] (2) A device for establishing a BIM demand progress model according to the demand plan;

[0030] (3) A device that identifies the two-dimensional code label of the information feature pasted on the steel component, and stores the serial number and scanning time of the steel component that has been identified and scanned;

[0031] (4) A device that triggers a real-time comparison of the planned delivery period and the actual delivery period plus the expected value T of the transportation time;

[0032] (5) A device that compares the scann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com