Following type ultrasonic flaw detector for rolling stock wheels

An ultrasonic and flaw detector technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, rim measurement/measurement, etc., can solve the problems of difficult quality control, large size of detection devices, complex structures, etc., to achieve information management, improve Detection efficiency and the effect of improving detection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

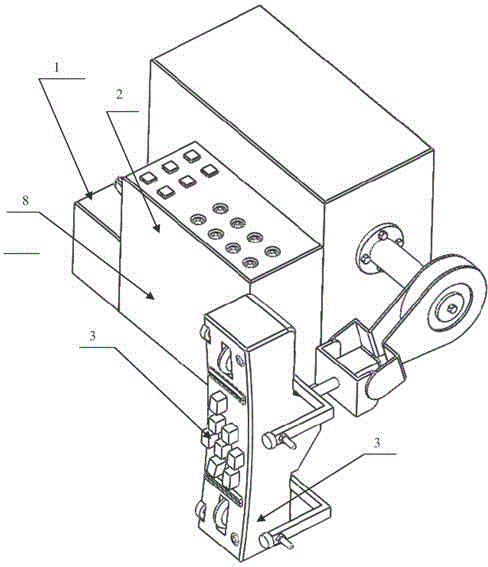

[0025] The follow-up locomotive and vehicle ultrasonic flaw detector of this embodiment includes a fixed workbench 1, an acquisition device 2, and an ultrasonic transducer device 3. The acquisition device is fixed on the fixed workbench 1, and the ultrasonic transducer device 3 is fixed on the fixed workbench 1. On the fixed workbench 1, the fixed workbench 1 is fixed on the shock absorber arm of the vehicle or the position of the vehicle body,

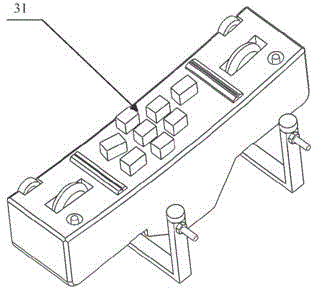

[0026] The ultrasonic transducer device 3 includes: a transducer carrier action mechanism 31, a probe 32, an encoder 33, a position sensor 34 and a couplant circuit 35, the encoder 33 is arranged at the front and back of the probe 32, and the couplant circuit 35 Arranged at the corresponding position with the encoder 33, the probe, the encoder and the couplant circuit are arranged on the transducer carrier action mechanism 31, and the position sensor 34 is arranged on the transducer rotation mechanism 31. The present invention comprehe...

Embodiment 2

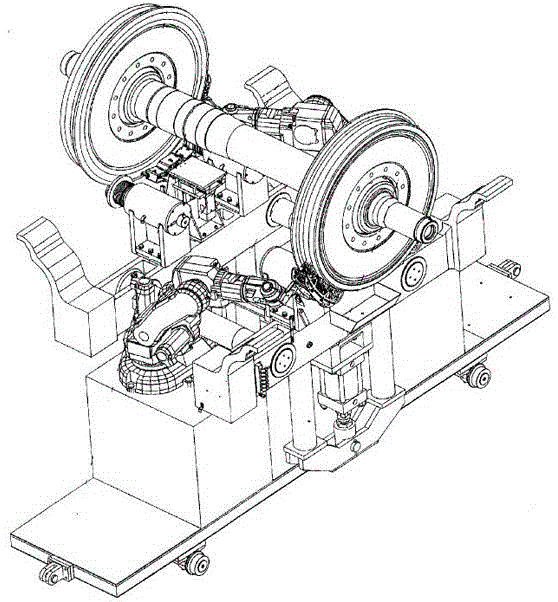

[0028] Such as figure 1 As shown, in the follow-up rolling stock ultrasonic flaw detector of this embodiment, when the wheel of the rolling stock needs to be inspected for defects, the defect detection device is installed on the special adapter, and it is closely fitted to connect the couplant pipeline. Flaw detection is realized under low-speed motion state.

[0029] Work process and principle of the present invention are:

[0030] When working, the following type rolling stock ultrasonic flaw detector is directly fixed on the working platform 1 on the shock absorbing arm of the rolling stock. The working platform 1 is connected with a movable flaw detection device 2. The flaw detection device includes an ultrasonic probe, an encoder and a coupling The agent pipeline, the sampling proximity switch, the acquisition device 2, and the connecting rotating mechanism 3 of the fixed flaw detection device. Under normal working conditions, the connecting rotating mechanism follows t...

Embodiment 3

[0034] Such as Figure 5 As shown, the follow-up ultrasonic flaw detector for locomotives in this embodiment is installed on the main body 7 of the shock absorber arm.

[0035] Such as Figure 6 , Figure 7 As shown, the follow-up type locomotive and vehicle ultrasonic flaw detector of this embodiment is installed on the vehicle body 5 .

[0036] The similarities and differences between its working method and Embodiment 1 are that the installation method is moved to the vehicle body, and the transducer detection device is fixed above. The transducer carrier action mechanism is different from the transducer carrier action mechanism on the shock absorber arm fixing mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com