A kind of flower structure SB2S3 material and preparation method thereof for sodium ion battery negative electrode

A sodium-ion battery, flower-like structure technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of small contribution to the improvement of battery electrochemical performance, large environmental pollution of sulfur sources, and restrictions on mass production, etc. Excellent electrochemical performance, improving the effect of low capacity, reducing environmental pollution and human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) 0.2g SbCl 3 Add 10mL dodecanethiol, stir until Sb 2 S 3 Solution A was obtained after complete dissolution.

[0029] 2) Add 0.26g of thioacetamide into 10mL of ethanol, and ultrasonicate for 10min until completely dissolved to obtain solution B.

[0030] Solution A was added dropwise to solution B to obtain mixed solution C. The mixed solution was initially colorless, and turned yellow as the reaction progressed, and precipitates occurred.

[0031] 3) Transfer the mixed liquid C to a polytetrafluoroethylene hydrothermal kettle, place it in a homogeneous reactor, and then react at 140°C for 15 hours. After the reaction is completed, it is naturally cooled to room temperature, and then precipitated by centrifugation. The obtained precipitate was vacuum freeze-dried (-50°C, 20Mpa, ~24h) to obtain the flower-like structure Sb for the negative electrode of the sodium-ion battery 2 S 3 Powder.

Embodiment 2

[0033] 1) 2.57g SbCl 3 Add 25mL dodecanethiol, stir until Sb 2 S 3 Solution A was obtained after complete dissolution.

[0034]2) Add 2.11g of thioacetamide into 25mL of ethanol, and sonicate for 20min until completely dissolved to obtain solution B. Solution A was added dropwise to solution B to obtain mixed solution C. The mixed solution was initially colorless, and turned yellow as the reaction progressed, and precipitates occurred.

[0035] 3) After transferring the mixed liquid C to a polytetrafluoroethylene hydrothermal kettle, place the polytetrafluoroethylene hydrothermal kettle in a homogeneous reactor, then react at 160°C for 20h, and cool to room temperature naturally after the reaction, Then the precipitate is separated by centrifugation, and the separated precipitate is vacuum freeze-dried (-50°C, 20Mpa, ~24h) to obtain the flower-like structure Sb for the negative electrode of the sodium ion battery. 2 S 3 Powder.

Embodiment 3

[0037] 1) 5.34g SbCl 3 Add 40mL dodecanethiol, stir until Sb 2 S 3 Solution A was obtained after complete dissolution.

[0038] 2) Add 4.47g of thioacetamide into 40mL of ethanol, and ultrasonicate for 30min until completely dissolved to obtain solution B. Solution A was added dropwise to solution B to obtain mixed solution C. The mixed solution was initially colorless, and turned yellow as the reaction progressed, and precipitates occurred.

[0039] 3) After transferring the mixed liquid C to a polytetrafluoroethylene hydrothermal kettle, place the polytetrafluoroethylene hydrothermal kettle in a homogeneous reactor, then react at 180°C for 24h, and cool to room temperature naturally after the reaction, Then the precipitate is separated by centrifugation, and the separated precipitate is vacuum freeze-dried (-50°C, 20Mpa, ~24h) to obtain the flower-like structure Sb for the negative electrode of the sodium ion battery. 2 S 3 Powder.

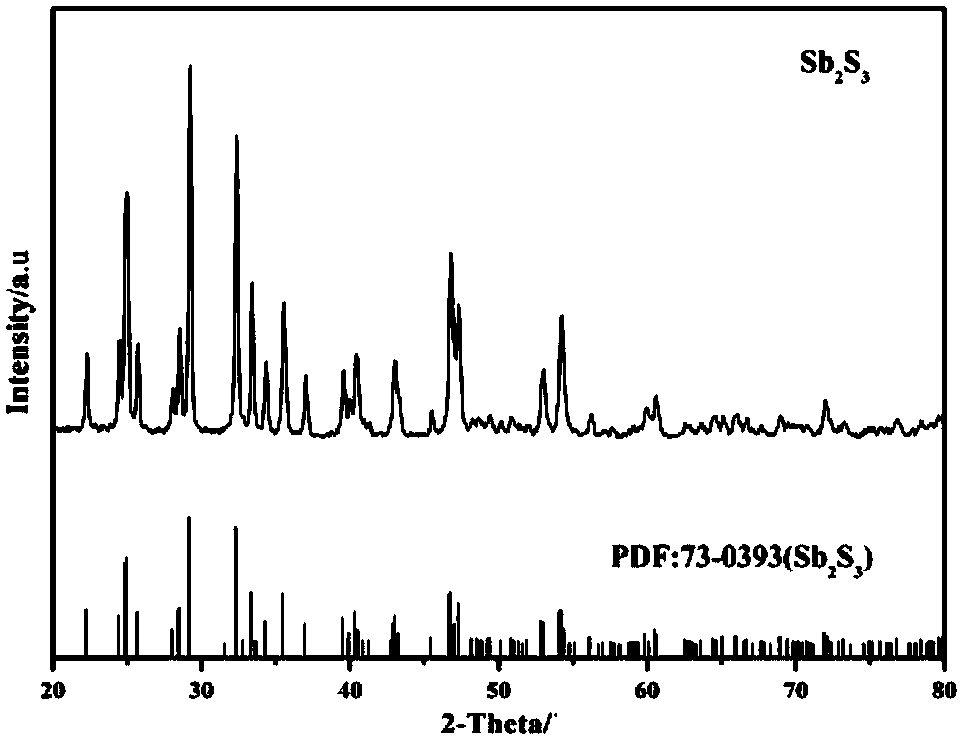

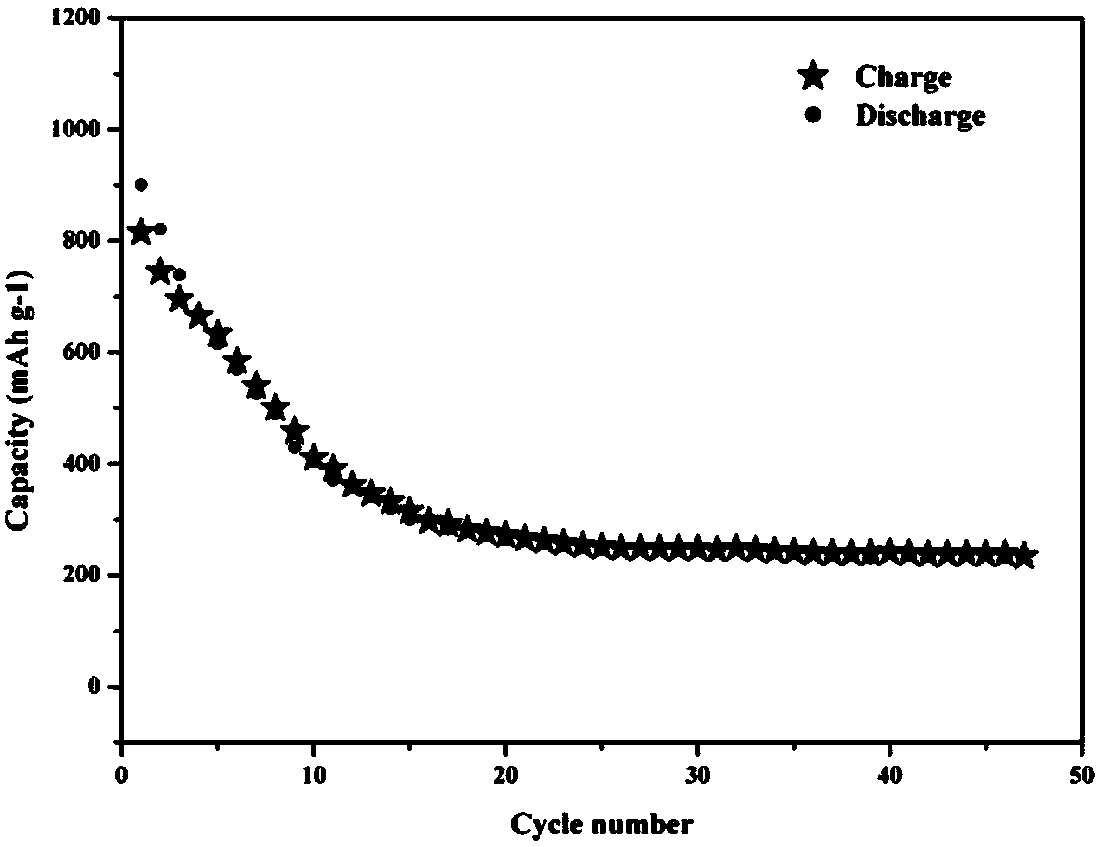

[0040] 4) Analyze the sample (Sb ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com