Carbon-ceramic coated aluminum foil current collector and preparation method therefor

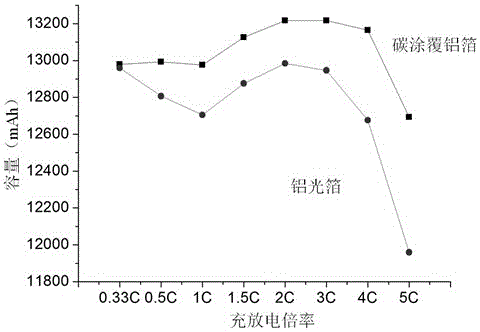

A current collector, ceramic coating technology, applied in electrode carrier/current collector, electrical components, battery electrodes, etc., can solve the problem of unsatisfactory corrosion resistance, poor film-forming agent binding force, and poor coating wettability, etc. problems, to achieve the effects of good wettability, improved mechanical properties and stability, and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

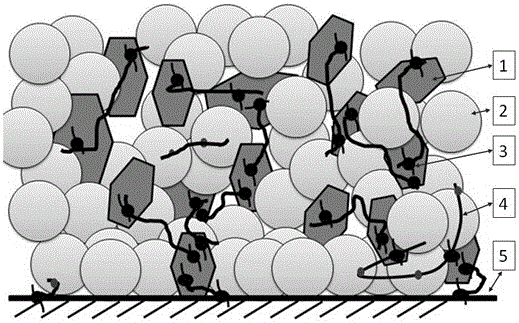

[0028] A carbon-ceramic coated aluminum foil current collector, the aluminum foil of the current collector is coated with a slurry coating containing ceramics and carbon materials on at least one side, and the slurry is composed of the following components in weight percentage:

[0029]

[0030]

[0031] The preparation method of carbon-ceramic coating aluminum foil current collector:

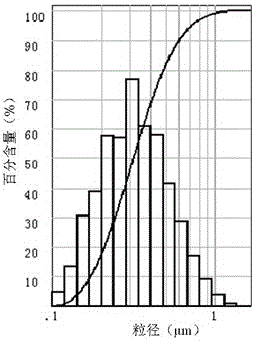

[0032] Dissolve polyvinylpyrrolidone dispersant in deionized water, add defoamer, stir and mix evenly, add Al 2 o 3 Particles, then add carbon black and graphite flakes three times, pre-disperse at 1000r / min for 1 hour under circulating water cooling at 4°C; transfer to a sand mill, sand mill for 10 hours under circulating water cooling at 4°C, and add coupling agent KH-550, acrylic resin emulsion, and substrate wetting agent are fully stirred to form a slurry; after testing, the solid content of the slurry is 14.5%, and the viscosity at a shear rate of 10 / S is 26mPa·S.

[0033] The abo...

Embodiment 2

[0035] A carbon-ceramic coated aluminum foil current collector, the aluminum foil of the current collector is coated with a slurry coating containing ceramics and carbon materials on at least one side, and the slurry is composed of the following components in weight percentage:

[0036]

[0037]

[0038] The preparation method of carbon-ceramic coating aluminum foil current collector:

[0039] Dissolve polyvinylpyrrolidone dispersant in deionized water, add defoamer, stir and mix evenly, add BN particles, then add carbon black and graphene in three times, and pre-disperse at 1000r / min for 2 hours under the cooling condition of circulating water at 4°C ; Transfer to a sand mill, sand mill for 8 hours under circulating water cooling at 4°C, add coupling agent KH-560, water-based polyurethane emulsion, and substrate wetting agent, and stir well to form a slurry; after testing, the slurry The solid content is 22%, and the viscosity at 10 / S shear rate is 40mPa·S.

[0040] Th...

Embodiment 3

[0042] A carbon-ceramic coated aluminum foil current collector, the aluminum foil of the current collector is coated with a slurry coating containing ceramics and carbon materials on at least one side, and the slurry is composed of the following components in weight percentage:

[0043]

[0044] The preparation method of carbon-ceramic coating aluminum foil current collector:

[0045] Dissolve the carbon black dispersant in xylene, stir and mix evenly, add Si 3 N 4 Particles, then add carbon black and carbon nanotubes three times, pre-disperse at 1000r / min for 1.5h under circulating water cooling at 4°C; transfer to a sand mill, sand mill for 8h at 4°C circulating water cooling, add titanium The ester coupling agent and the phenolic resin are fully stirred to form a slurry; after testing, the solid content of the slurry is 17%, and the viscosity at a shear rate of 10 / S is 200mPa·S.

[0046] The above slurry was coated on an aluminum foil using a micro-gravure printing coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap