Liquid pipeline built-in compact type aluminum-air fuel cell monomer

A fuel cell, compact technology, applied in the direction of fuel cell half-cells and primary battery-type half-cells, etc., can solve the problems of battery internal current increase, complex structure, large size, etc., to reduce external dimensions and small volume , The effect of solving the liquid connection problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

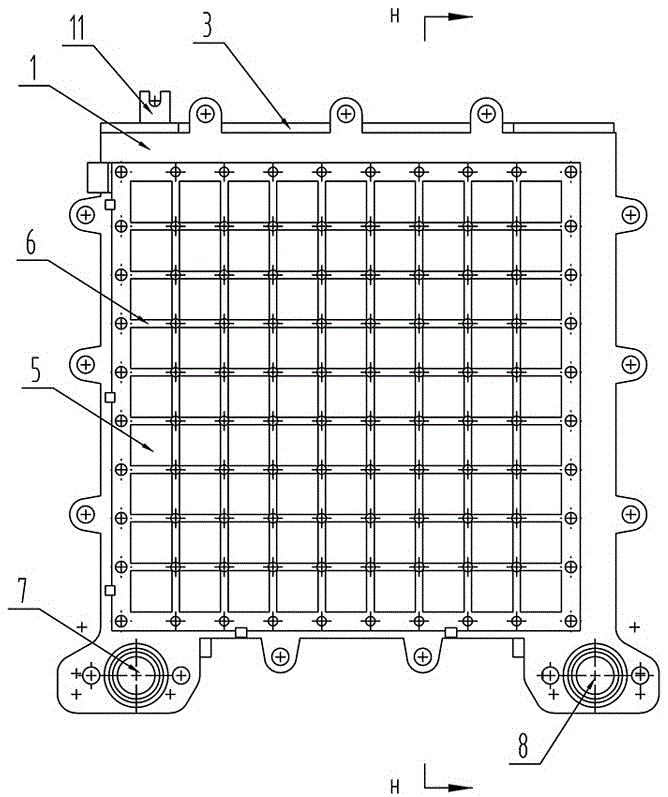

[0024] The orientations of front and rear, left and right, and up and down involved in the specific implementation of the present invention are described in the accompanying drawings figure 1 The display in is for reference.

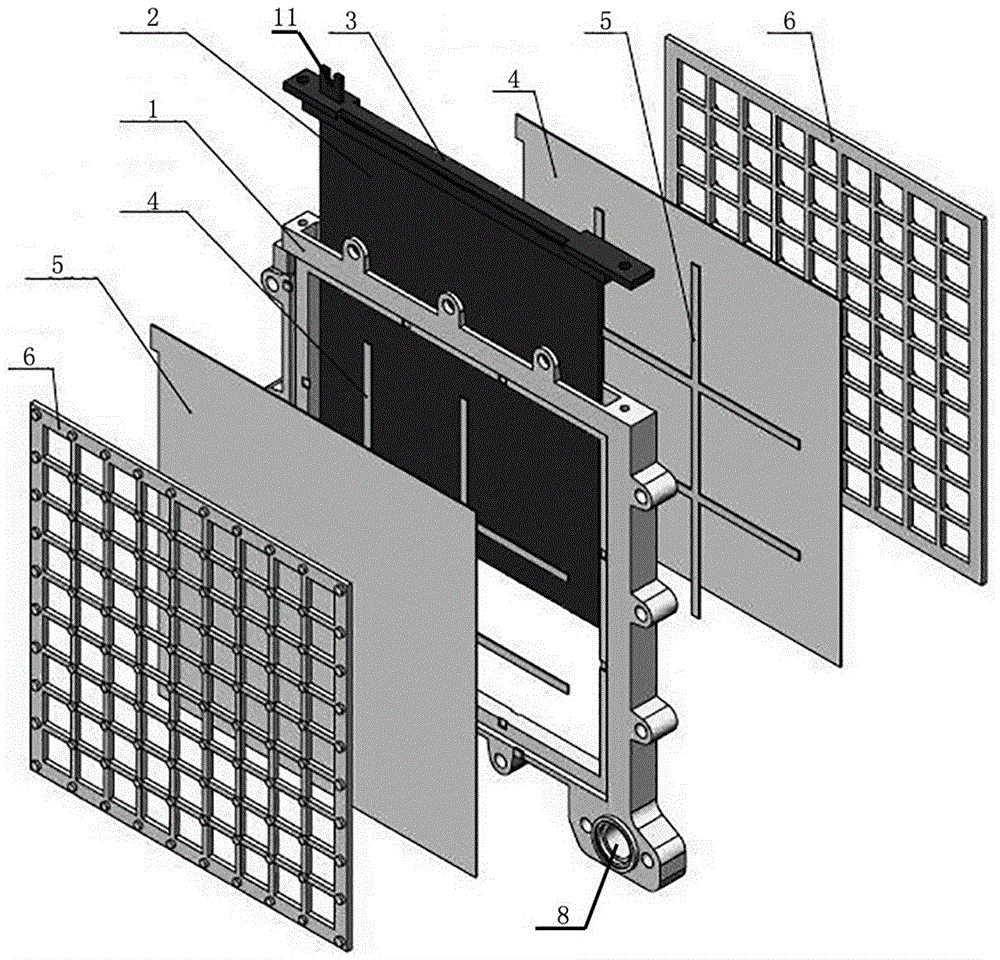

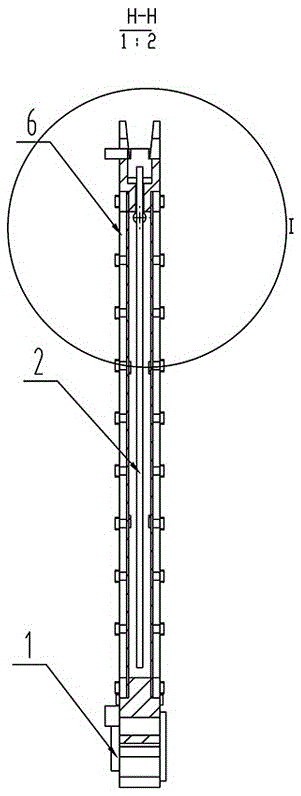

[0025] Such as Figure 1~7 As shown, a compact aluminum-air fuel cell unit with a built-in liquid circuit includes a casing 1 with a square frame structure, and an aluminum electrode 2 is arranged inside the casing 1 through an aluminum electrode seat 3. The two opposite sides of the casing 1 Each side is respectively provided with an inner grid 4 of a well-shaped structure, each outer side of each inner grid 4 is respectively provided with an air electrode 5, and each outer side of each air electrode 5 is respectively provided with a grid plate 6; each air An extension is provided on one side of the electrode 5, and a sealing ring is provided between the aluminum electrode holder 3 and the casing 1; the air electrode 5 and the casing 1 are closely atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com