Balance weights for motors, motors for compressors and compressors

A technology of balance weights and compressors, which is applied in the direction of machines/engines, electromechanical devices, electrical components, etc., which can solve the problems of reducing compressor efficiency, increasing rotor rotation resistance, and breaking oil droplets, so as to reduce atomization of oil droplets, The effect of reducing the amount of oil spit out and the amount of oil spit out is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

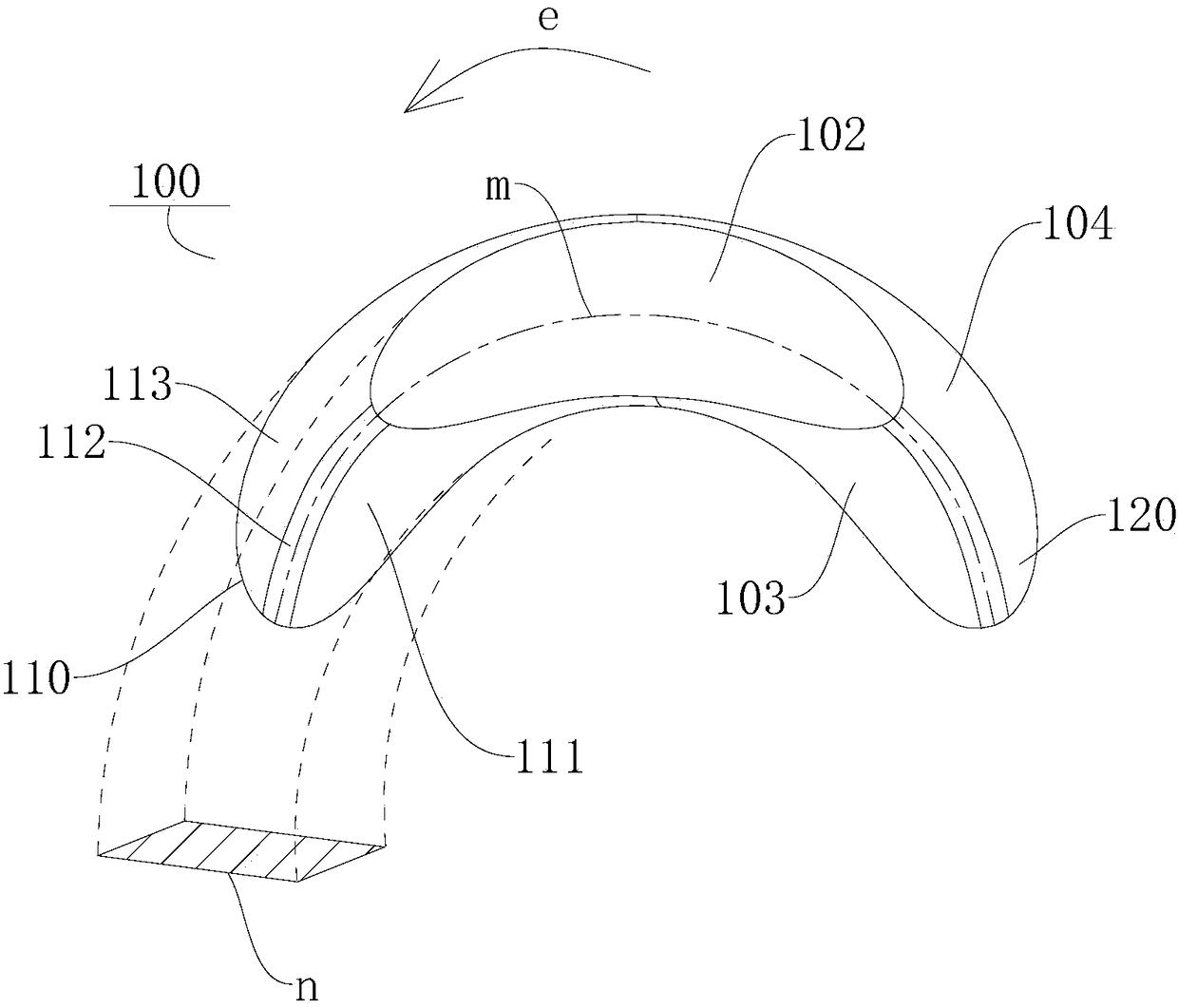

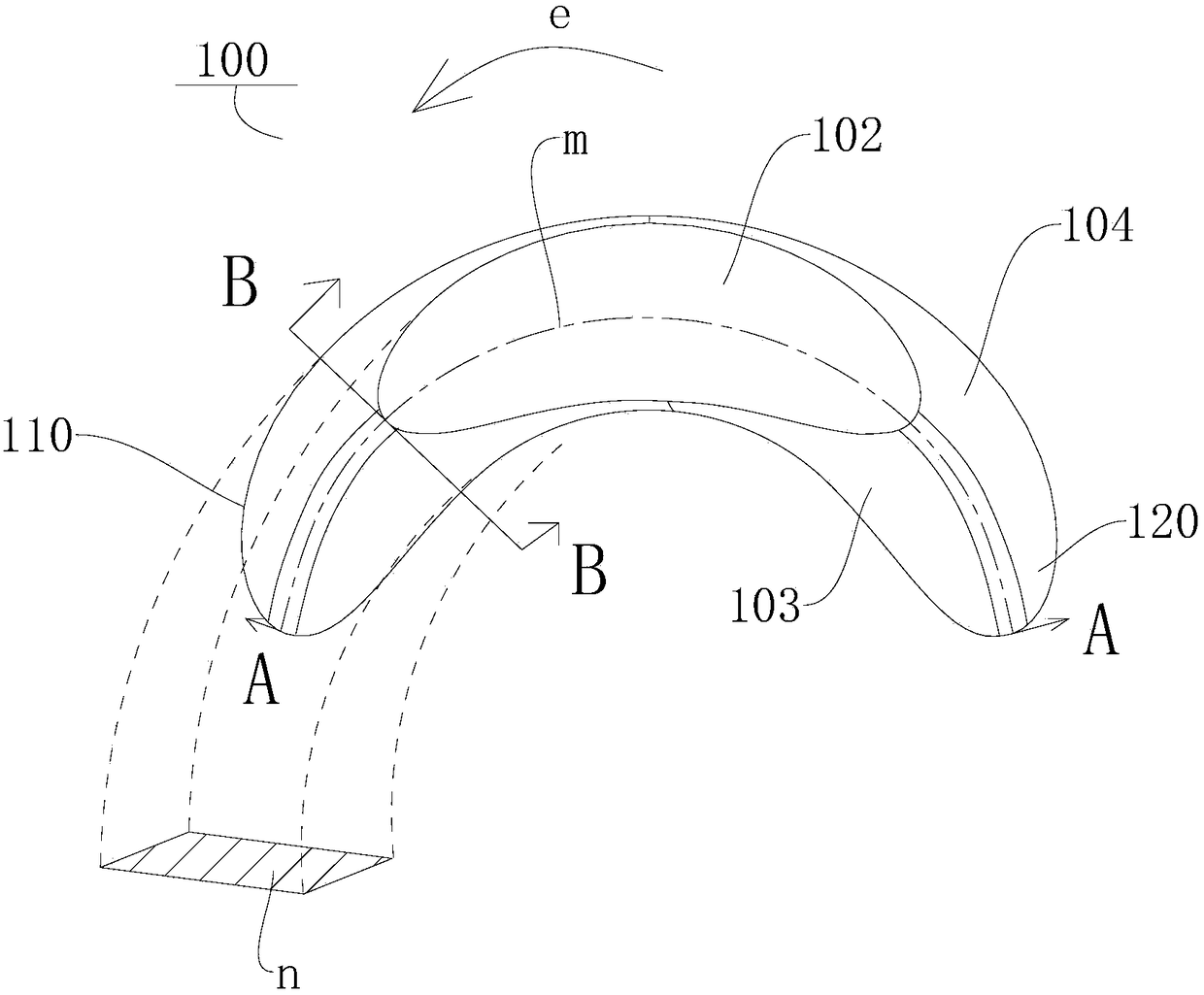

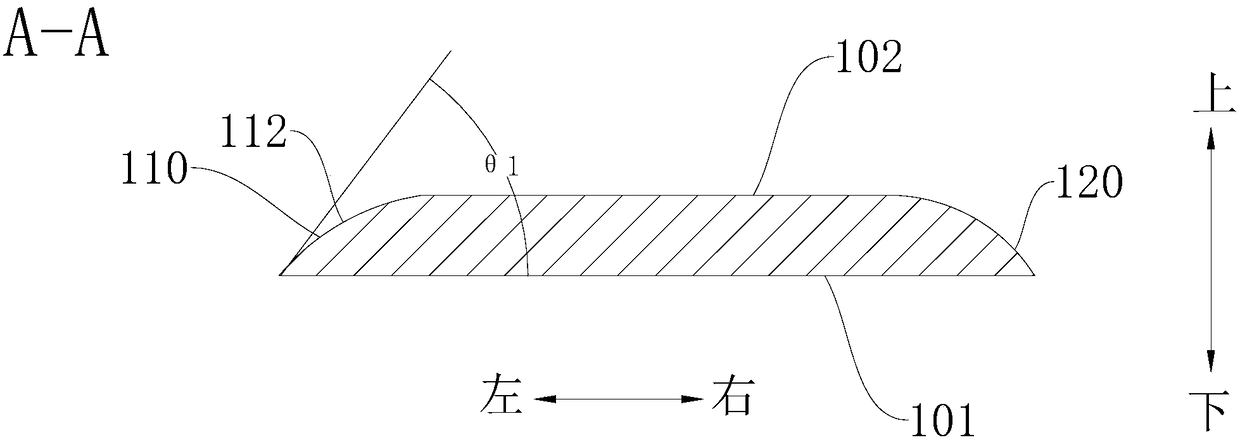

[0049] Such as Figure 1-Figure 7 As shown, in this embodiment, the balance weight 100 has a first end surface 101 and a second end surface 102 oppositely arranged, as Figure 5 As shown, the lower end surface of the balance weight 100 is the first end surface 101 , and the upper end surface of the balance weight 100 is the second end surface 102 . The first end surface 101 is suitable for connecting with the rotor of the motor, and the two ends of the balance weight 100 in the extension direction are a windward end 110 and a leeward end 120 respectively. Such as figure 1 As shown, the arrow e is the direction in which the rotor rotates. The rotor can drive the balance weight 100 to rotate in the direction indicated by the arrow e. The leeward end 120 is located upstream of the rotor's rotational direction, and the windward end 110 is located downstream of the rotor's rotational direction. The windward end portion 110 is connected between the first end surface 101 and the se...

Embodiment 2

[0056] Such as Figure 8 As shown, the difference from Embodiment 1 is that in this embodiment, the intersection line of the inner side flow distribution surface 111 and the outer side flow distribution surface 113 is configured as the middle windward portion 112 . Thus, the windward area of the balance weight 100 can be further reduced, thereby reducing the windward resistance, preventing the oil droplets carried in the refrigerant airflow from colliding with the wall of the balance weight 100 vertically, reducing the atomization of the oil droplets caused by the rotation of the balance weight 100, The oil discharge volume of the compressor is reduced, so that the compressor has the advantages of high energy efficiency and small oil discharge volume.

[0057] The motor of the compressor according to the embodiment of the present invention includes: the rotor and the balance weight 100 of the motor described in the above embodiments. Specifically, the balance weight 100 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com