Frequency conversion motor heat dissipation method, air conditioner

A heat dissipation method and frequency conversion motor technology, applied in the direction of AC motor control, electromechanical devices, electrical components, etc., can solve the problem that the heat dissipation effect of the frequency conversion motor cannot meet the actual needs, and achieve the effect of improving the heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

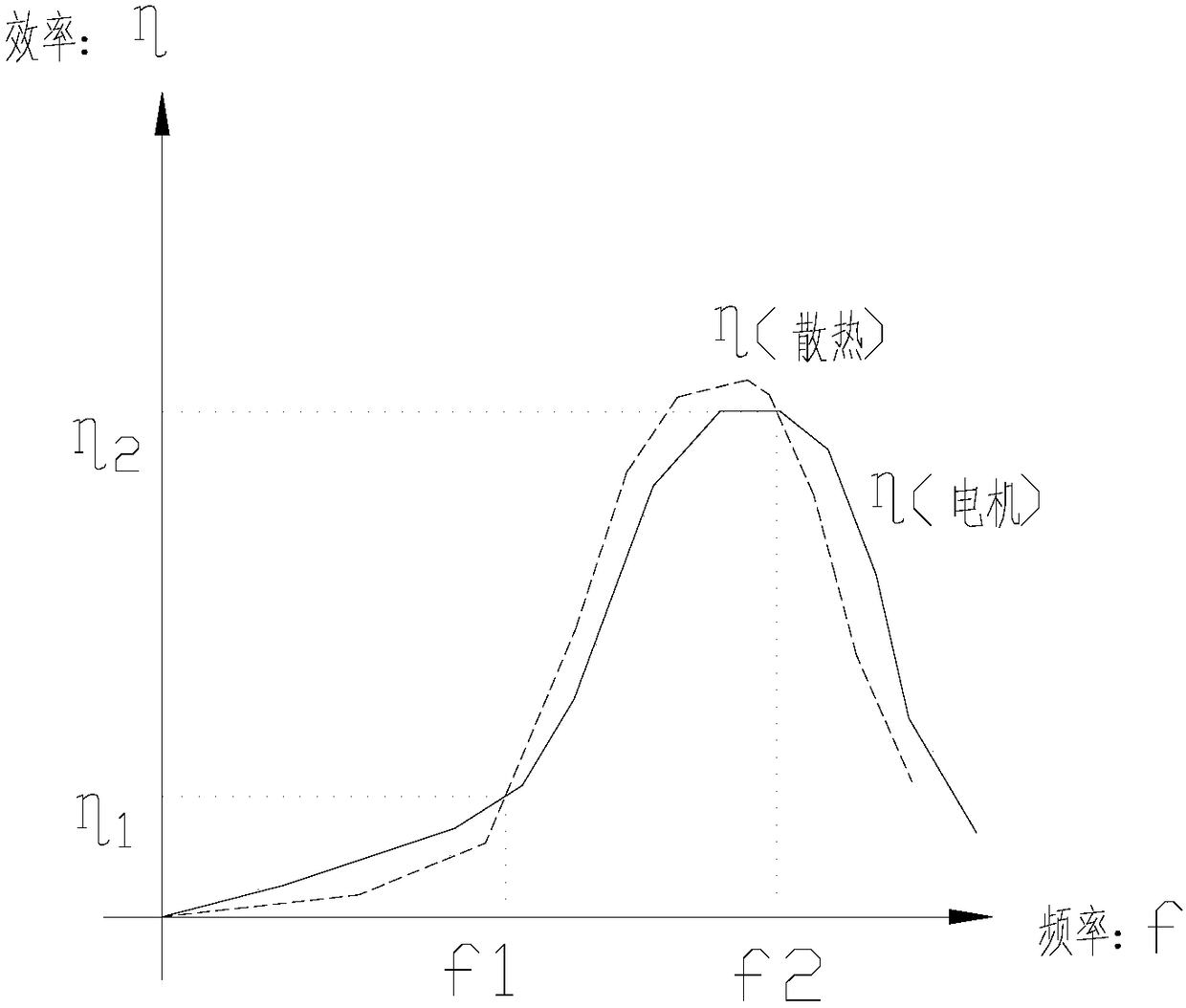

[0036] like figure 1 As shown, according to one aspect of the present invention, a cooling method for a variable frequency motor is provided. According to the first embodiment provided by the present invention, the method includes determining the motor efficiency of the motor according to the frequency of the motor, determining the fan efficiency of the fan according to the frequency of the fan, and finding out when the fan efficiency is not less than the motor efficiency according to the motor efficiency and the fan efficiency The frequency of the motor is used as the operating frequency of the motor.

[0037] In this embodiment, since the efficiency of the fan is not less than that of the motor, the attenuation of the heat dissipation of the motor winding is lower than the attenuation of the heat generation of the winding, so as to ensure that the temperature rise of the motor winding meets the requirements of actual use. The use frequency of the motor when the motor and th...

no. 2 example

[0038] According to the second embodiment of the present invention, the method includes firstly determining the motor efficiency of the motor according to the frequency of the motor, secondly determining the fan efficiency of the fan according to the frequency of the fan, and then finding out when the fan efficiency is not less than the motor efficiency according to the motor efficiency and the fan efficiency The frequency of the motor is used as the frequency of the motor. Among them, the efficiency curves of motor efficiency and fan efficiency can be drawn in the same coordinate system, and then the frequency of use of the motor can be determined intuitively from the graph. that is, figure 1 As shown, the solid line η (motor) in the figure represents the motor efficiency of the variable frequency motor in this embodiment, and the efficiency of the motor is drawn according to each frequency point of the motor. The dotted line η (radiation) in the figure represents the effici...

no. 3 example

[0039] According to the third embodiment of the present invention, the method includes firstly determining the motor efficiency of the motor according to the frequency of the motor, secondly determining the fan efficiency of the fan according to the frequency of the fan, and then finding out when the fan efficiency is not less than the motor efficiency according to the motor efficiency and the fan efficiency The frequency of the motor is used as the frequency of the motor. If the motor efficiency is recorded as η1, the motor efficiency can be obtained by the following formula:

[0040] η1=T×60×f1×(1-s) / (9.55×P 输入 ×p), where T is the output torque of the motor, s is the slip of the motor, p is the number of pole pairs of the motor, f1 is the frequency of the motor, P 输入 is the input power of the motor. The output torque of the motor is obtained by the following formula:

[0041] T=9.55×P输出 / n1, where P 输入 is the input power of the motor, and n1 is the speed of the motor.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com