Punching and knurling forming device

A technology of pore pressing and forming molds, which is applied in medical science, clothing, underwear, etc., and can solve problems such as displacement, difficulty in maintaining the 3D effect of three-dimensional non-woven fabrics, and small bonding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

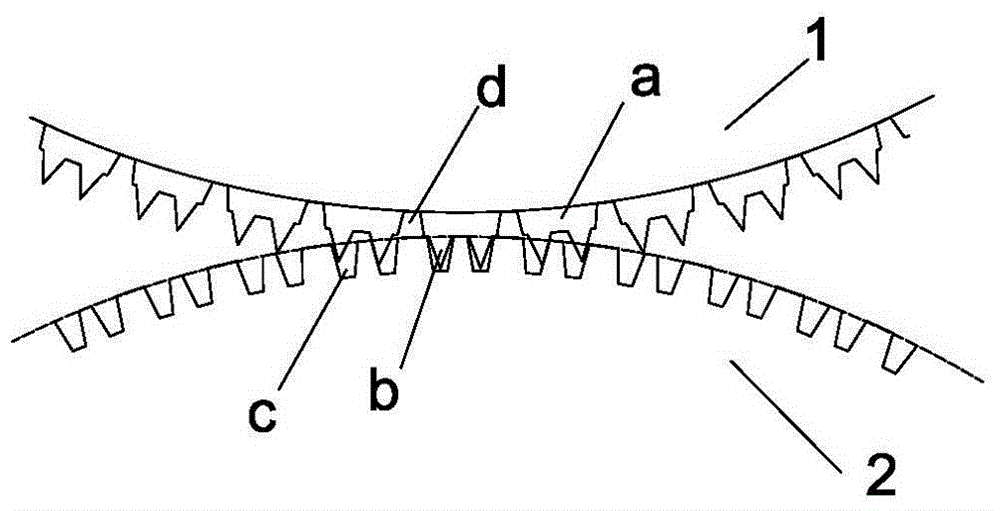

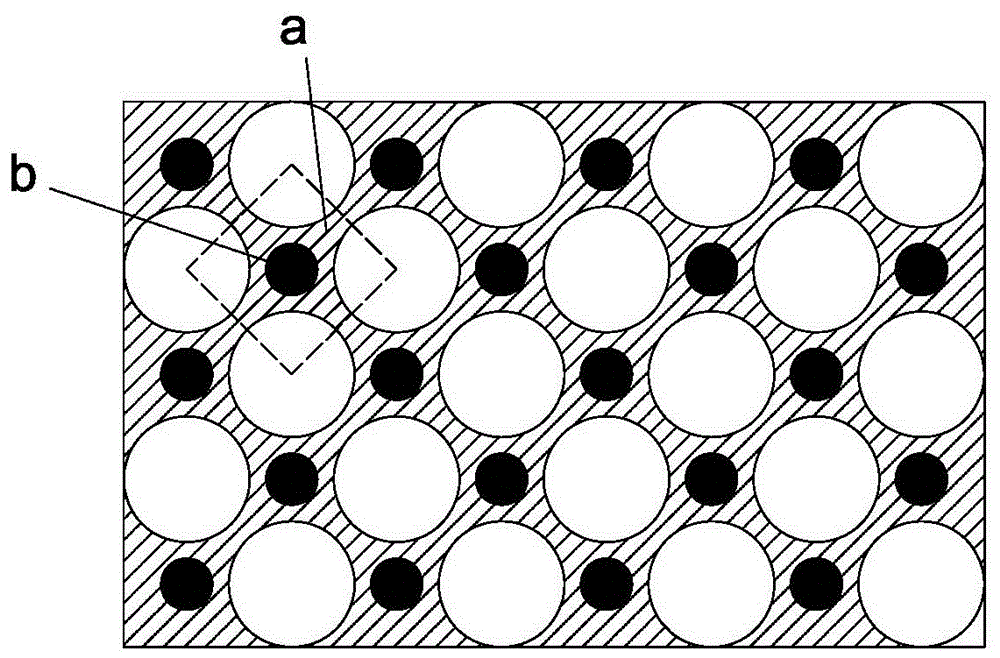

[0027] Such as image 3 , as shown in 4, the perforated embossing molding die of the present invention includes a needle roll 1 and a concave roll 2 that are engaged with each other, wherein the surface of the needle roll 1 has a perforating needle composed of a platform a and a cone b, and the platform The upper bottom surface of the body a is connected with a cone b, and the lower bottom surface of the table body a is connected with the core of the needle roller 1 . Such as image 3 The dotted line in the middle represents a single tine, where the area of the upper bottom of a single platform a on the tine is 10mm 2 , the height is 0.5mm, the shape of the bottom surface is irregular, and the bottom surface area of a single cone b on the punching needle is 3mm 2 , the height is 2.5mm, the bottom surface area of the cone b is smaller than the upper bottom surface area of a single table body 3a; the surface of the concave roller 2 has a concave hole c corresponding to...

Embodiment 2

[0030] Such as Figure 5 , as shown in 6, the perforated embossing molding die of the present invention comprises a needle roller 1 and a concave roller 2 that are engaged with each other, wherein the surface of the needle roller 1 has a perforating needle composed of a platform a and a cone b, and the platform The upper bottom surface of the body a is connected with the four cones b, and the lower bottom surface of the table body is connected with the needle roller core. Such as Figure 5The dotted line in the middle indicates a single tine, where the area of the upper bottom of a single platform b on the tine is 60mm 2 , the height is 1.0mm, the bottom surface is a regular polygon, and the bottom surface area of a single cone b on the punching needle is 4mm 2 , the height is 1.5mm, the bottom surface area of the four cones b is smaller than the upper bottom surface area of a single platform a; the surface of the concave roller 2 has a concave hole c corresponding t...

Embodiment 3

[0033] Such as Figure 7 , shown in 8, the perforated embossing molding die of the present invention comprises a needle roll 1 and a concave roll 2 that are engaged with each other, wherein the surface of the needle roll 1 has a perforating pin composed of a table body a and a cone b, and the table The upper bottom surface of body a is connected with eighteen cones 7b, and the lower bottom surface of platform a is connected with needle roller 1 roller core. Such as Figure 7 The dotted line in the middle indicates a single tine, where the area of the upper bottom of a single platform a on the tine is 210mm 2 , the height is 1.0mm, the shape of the bottom surface is an irregular polygon, and the bottom surface area of a single cone b on the punching needle is 2mm 2 , the height is 2.0mm, the bottom surface area of the eighteen cones b is smaller than the upper bottom surface area of a single table body a; the surface of the concave roller 2 has a concave hole c corres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bottom area | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com