Laboratory-type vacuum homogenizing and emulsifying machine

A technology of vacuum homogenizer and emulsifier, applied in the field of emulsifier, can solve problems such as short circuit in the electrical part of the control system, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

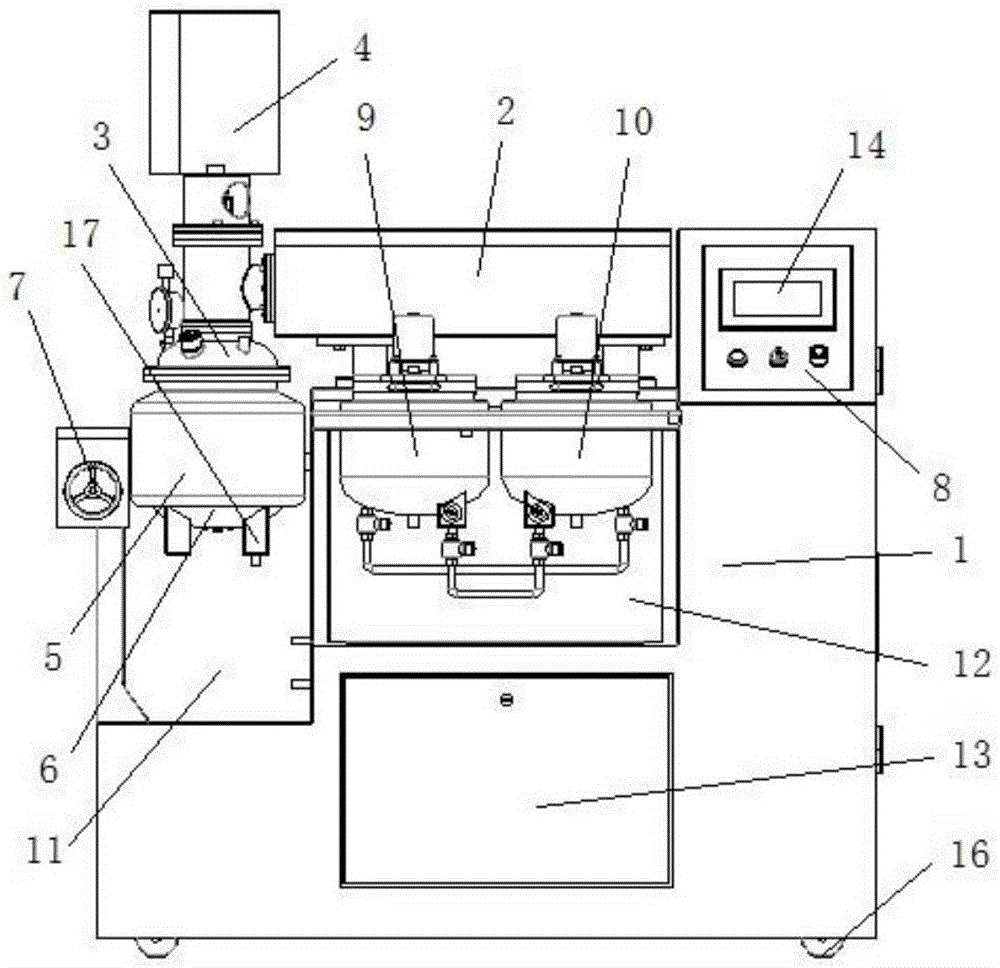

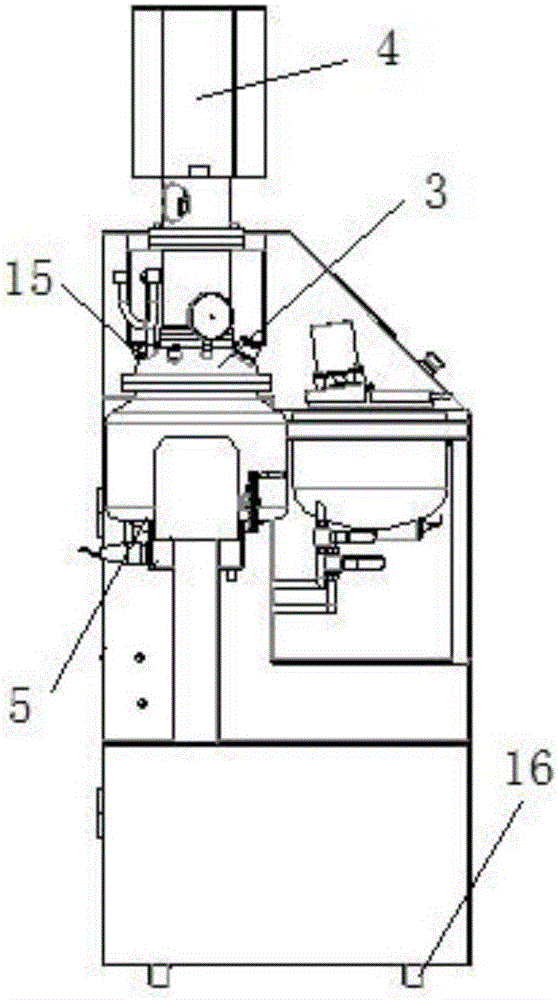

[0012] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings.

[0013] like figure 1 and figure 2 As shown, a laboratory-type vacuum homogeneous emulsifier includes a frame 1, a lifting device 2 arranged above the frame 1, a stirring pot cover 3 located at one end of the lifting device 2, and a driving motor above the stirring pot cover 3 4. The emulsification pot 5 located directly under the stirring pot cover 3, the heating device 6 located at the lower part of the emulsification pot 5, the pouring handle 7 located on the side of the body 1 close to the emulsification pot 5, and the body 1 away from the emulsification pot 5- The side control panel 8 and the water phase pot 9 and the oil phase pot 10 arranged between the emulsification pot 5 and the control panel 8, the frame 1 includes a first storage chamber 11, a second storage chamber 12 and a third storage cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com