Efficient mixing machine

A mixer and high-efficiency technology, used in mixers, mixers with rotary mixing devices, mixer accessories, etc., can solve the problems of occupying too much labor resources, not suitable for automatic production, uneven mixing, etc., and achieve high quality, The effect of low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

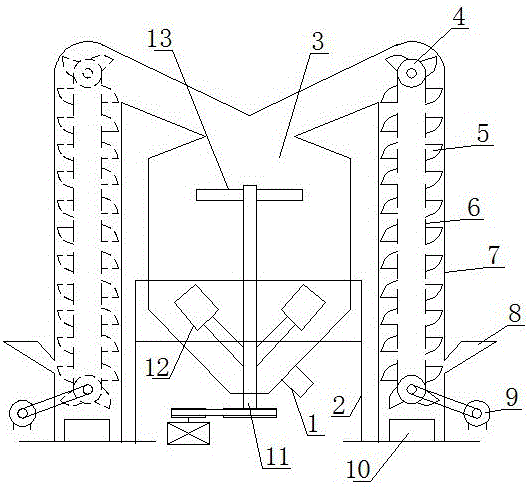

[0011] The accompanying drawing is a specific embodiment of the present invention.

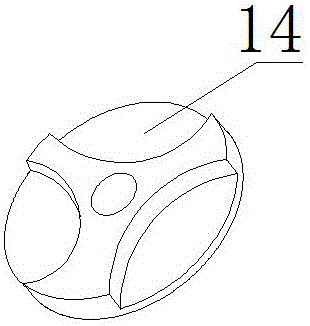

[0012] The high-efficiency mixer of the present invention is characterized in that: it comprises a mixing barrel 3 and two left and right lifting racks 7, the mixing barrel 3 is an inverted cone-shaped drum structure, and the bottom is held up and fixed by a bracket 2; the center of the mixing barrel 3 is provided with a rotating shaft 11. A dispersing wheel 13 is installed on the top of the rotating shaft 11, and the dispersing wheel 13 is provided with an arc-shaped groove 14 with an outwardly diffusing structure; the lower part of the rotating shaft 11 is provided with two left and right willow-shaped teeth 12 inclined at an angle of 45 degrees; the rotating shaft The bottom end of 11 protrudes out of the mixing barrel 3 and is equipped with a pulley, which is driven by a motor through a belt; a discharge port is provided on the conical surface of the mixing barrel 3; A vertical conveyor be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com