Device, method and system for row-by-row feeding of material tubes

A material reclaiming device and material pipe technology, applied in metal processing and other directions, can solve the problems of high labor intensity, single repetitive labor, waste of human and material resources, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

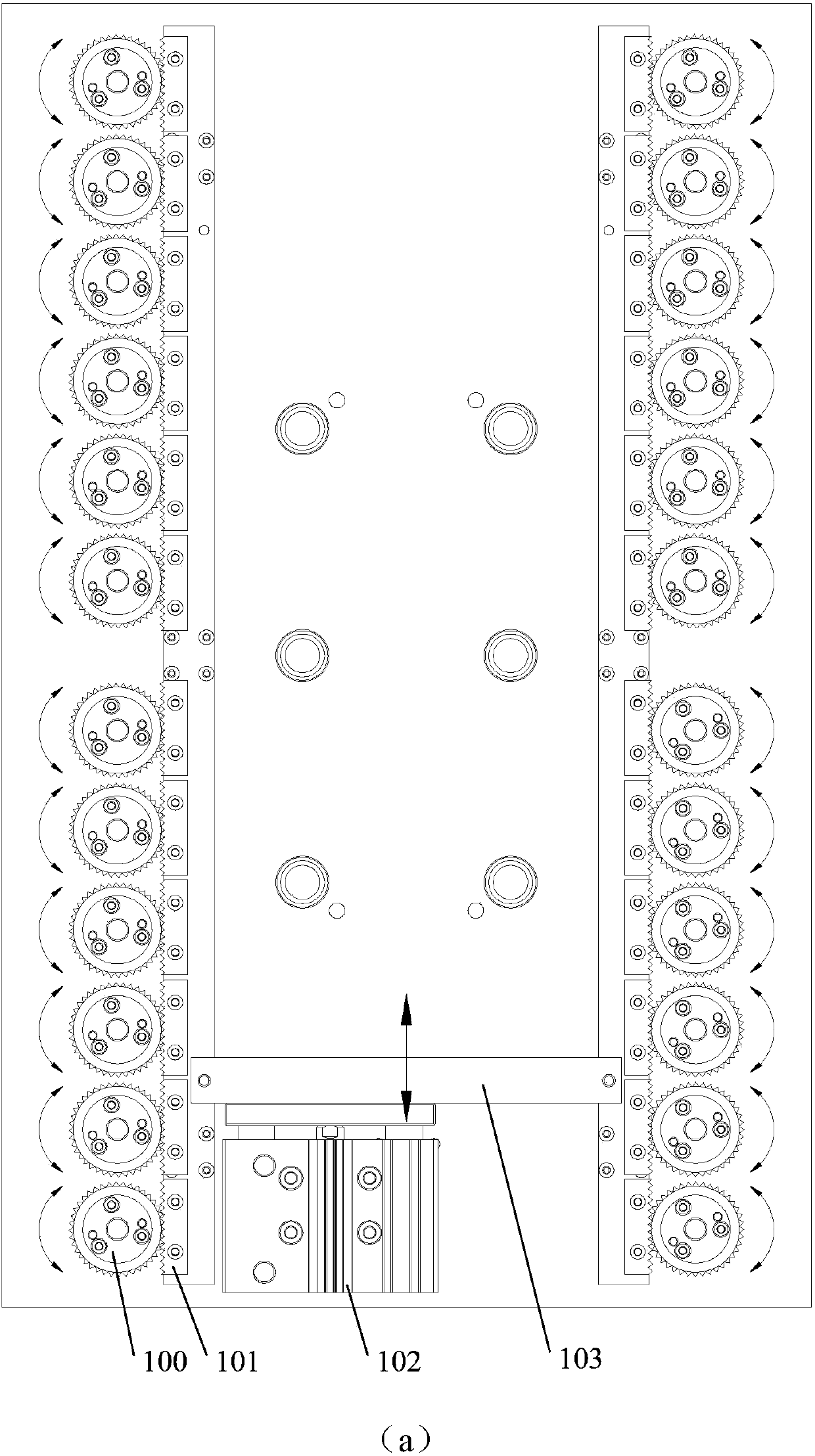

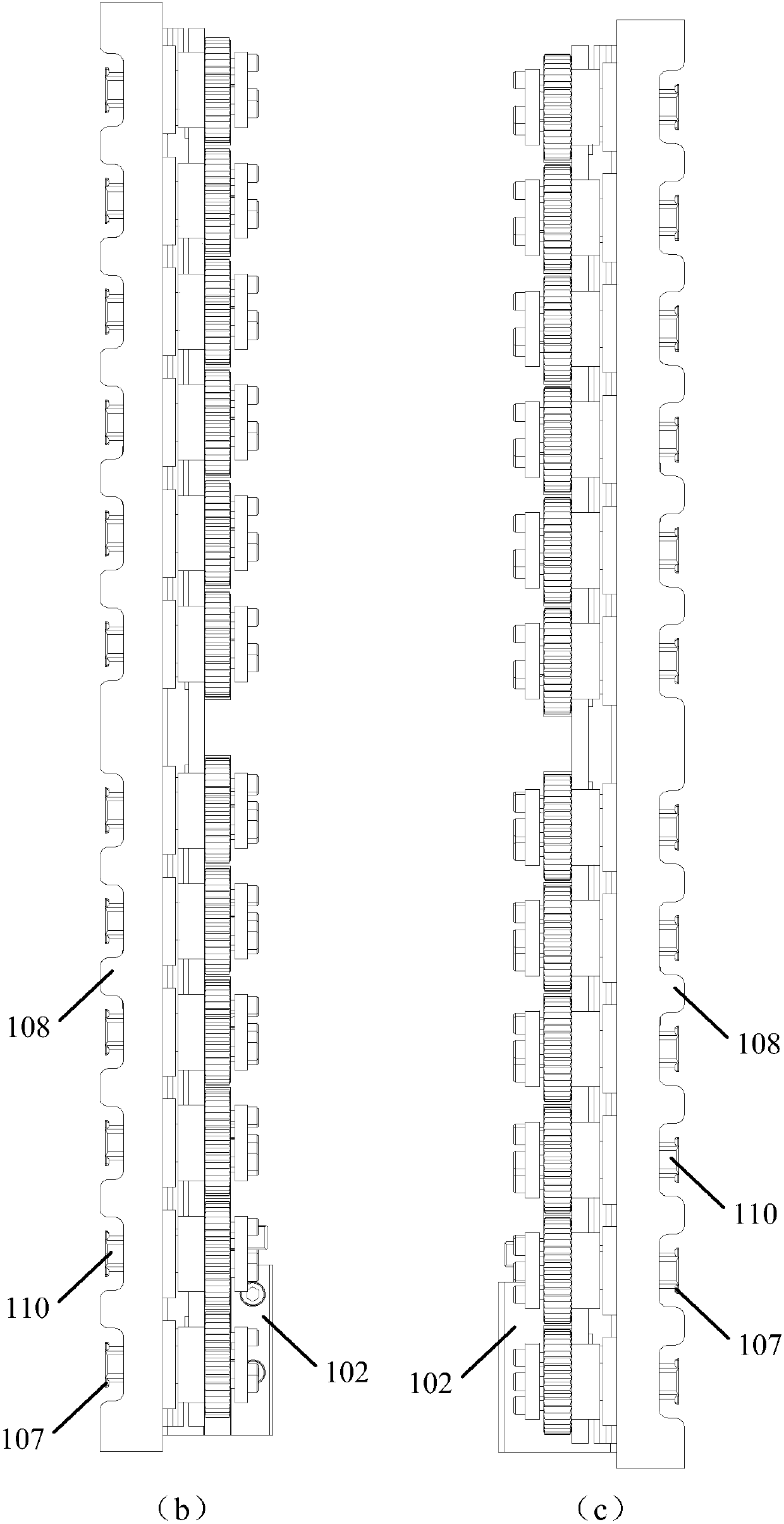

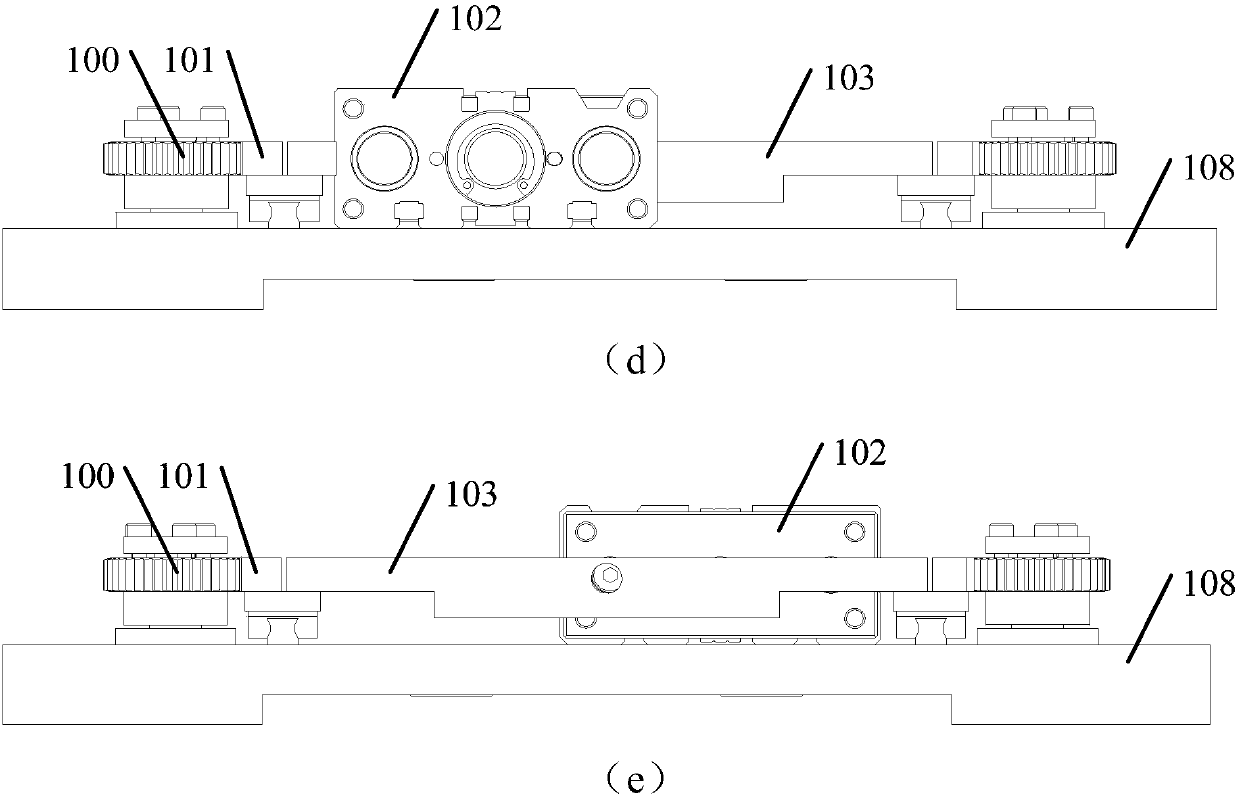

[0034] Such as Figure 1-5 As shown, the row-by-row reclaiming device for material tubes described in the embodiment of the present invention includes a base 108, two rows of rotating shafts 110 passing through the base 108, located above the base 108, and fixedly installed on the The swing mechanism of the rotating shaft 110 (preferably such as: gear 100 and rack 101; pendulum 105 and connecting rod 104), is located below the base 108 and is fixedly installed with the clamping mechanism of the rotating shaft 110 (for example: fixed on elongated plate or jaw 107 on the rotating shaft 110), and a driving mechanism (such as an air cylinder 102) that drives the swing of the swing mechanism; wherein,

[0035] Driven by the drive mechanism, the swing mechanism swings and drives the rotating shaft to rotate, and the rotating shaft 110 drives the clamping mechanism to rotate. When it is turned to the first position, the material tube is clamped between the clamping mechanism and the...

Embodiment 2

[0041] Such as Figure 1-5As shown, in this embodiment, on the basis of Embodiment 1, an accommodating portion 112 is provided at the bottom of the base 108 close to the rotating shaft 110, and the accommodating portion 112 is used for accommodating the material tube (such as Long straight tube or long U-shaped copper tube 106); Wherein, when the clamping mechanism turns to the first position, the material tube is clamped between the clamping mechanism and the accommodating part 112. Wherein, the tube length of the material tube is preferably 500-1500 mm.

[0042] Through the accommodating portion provided at the bottom of the base, when the clamping mechanism is turned to the first position, the material tube can be more stably clamped between the clamping mechanism and the accommodating portion, so that The material is more reliable and efficient, and it is also conducive to improving the versatility and flexibility of row-by-row retrieving; in addition, the setting of the ...

Embodiment 3

[0050] Such as figure 1 , image 3 As shown, this embodiment is based on Embodiment 1 and Embodiment 2. Preferably, the swing mechanism includes a gear 100 and a rack 101, the gear 100 is fixed on the rotating shaft 110, and the rack 101 and the rack 101 The drive mechanism is connected; the gear 100 is meshed with the rack 101; the drive mechanism is connected with the rack 101.

[0051] In this embodiment, the driving mechanism preferably uses an air cylinder 102 .

[0052] For example: the cylinder 102 includes a piston rod, the front end of the piston rod is provided with a push rod 103, and both ends of the push rod 103 are fixedly connected to the swing mechanism.

[0053] For the structure in which the swing mechanism is a rack and pinion, both ends of the push rod 103 are fixedly connected to the two racks 101 respectively. The rack 101 meshes with the gear 100 , the gear 100 is driven to rotate through the rack 101 , and the clamping mechanism is driven to rotate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com