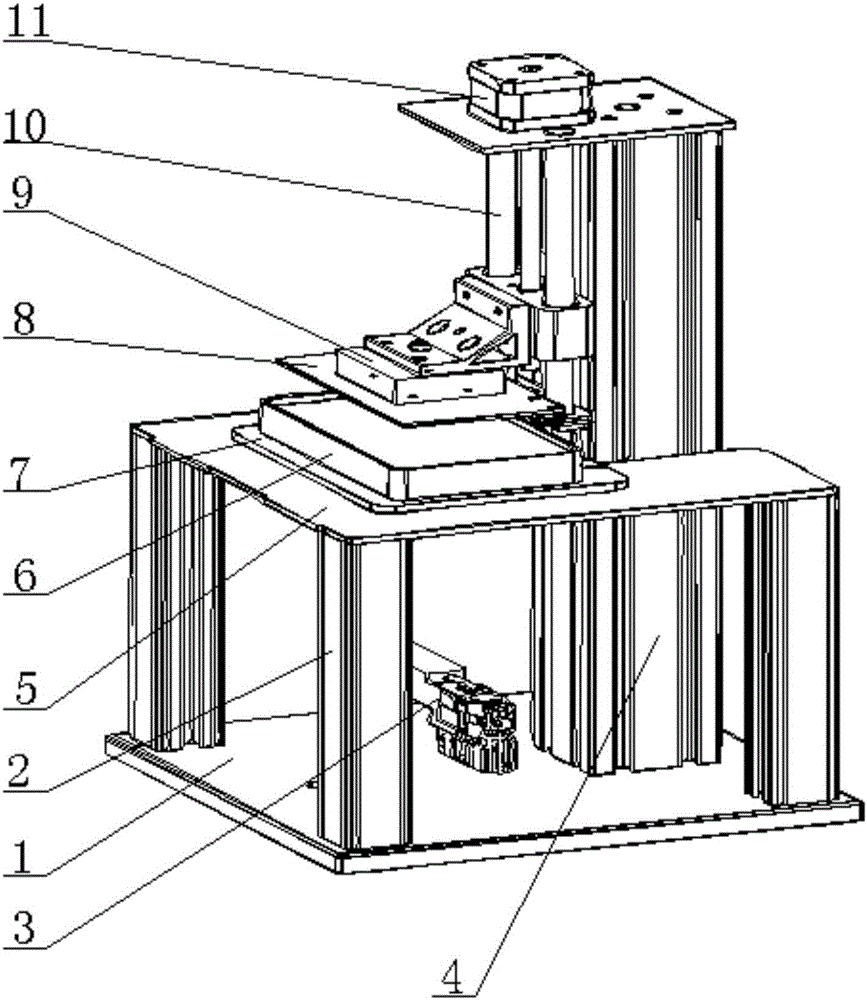

Stereo lithography apparatus and prototyping method thereof

A molding device and light-curing technology, applied in the field of light-curing, can solve problems such as increasing system complexity, and achieve the effect of improving precision and increasing overshooting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

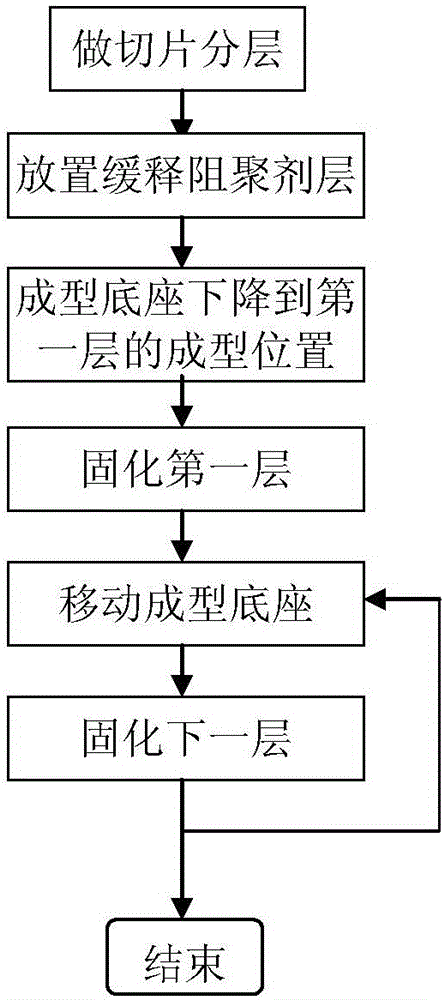

Method used

Image

Examples

Embodiment Construction

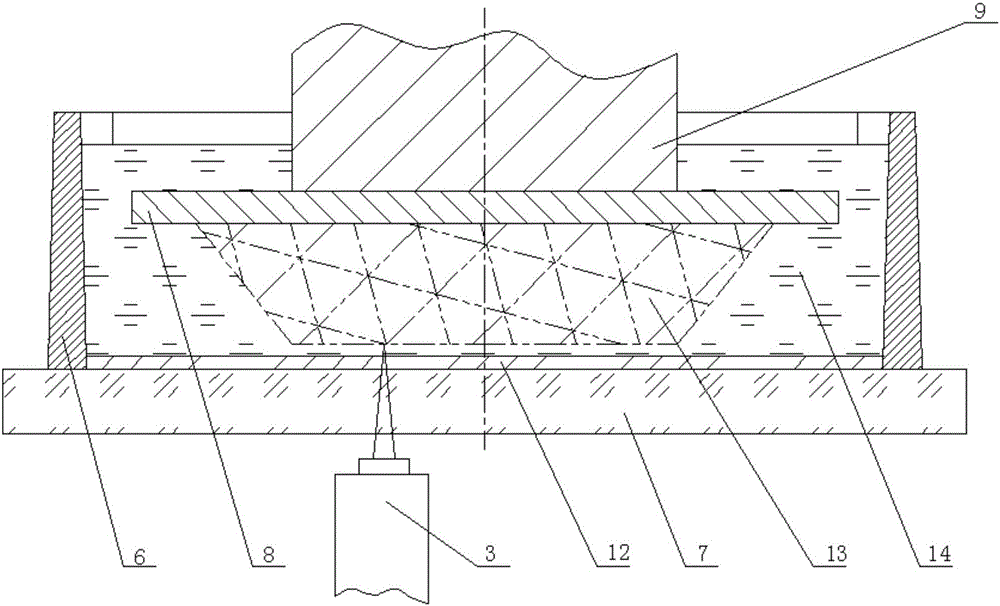

[0033] The main component of the curing liquid 14 is usually a resin or gel containing a monomer or a prepolymer, and the curing liquid 14 also contains a photoinitiator (also called a photosensitizer), and the photoinitiator absorbs the radiation of the curing light The energy generates active free radicals or ionic radicals, thereby initiating the polymerization, cross-linking and grafting reactions of the solidified liquid 14, making it change from liquid to solid in a few seconds. The curing light is usually ultraviolet light, but also other light rays, such as visible light, or higher-energy rays, such as X-rays.

[0034] When the solidified liquid 14 contains a polymerization inhibitor (such as oxygen), even if it is irradiated by curing light, the solidified liquid will not solidify or requires a larger dose of irradiation to solidify. The polymerization inhibition mechanism of oxygen has already been discussed publicly and will not be repeated here.

[0035] The prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com