Chassis for full electric vehicle

A pure electric vehicle and chassis technology, applied in the direction of electric power units, power units, vehicle components, etc., can solve the problems of unoptimized safety, prolonged charging time of the battery box, lack of overall protection of the battery box, etc., and achieve simple structure , Compact layout, satisfying the effect of installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

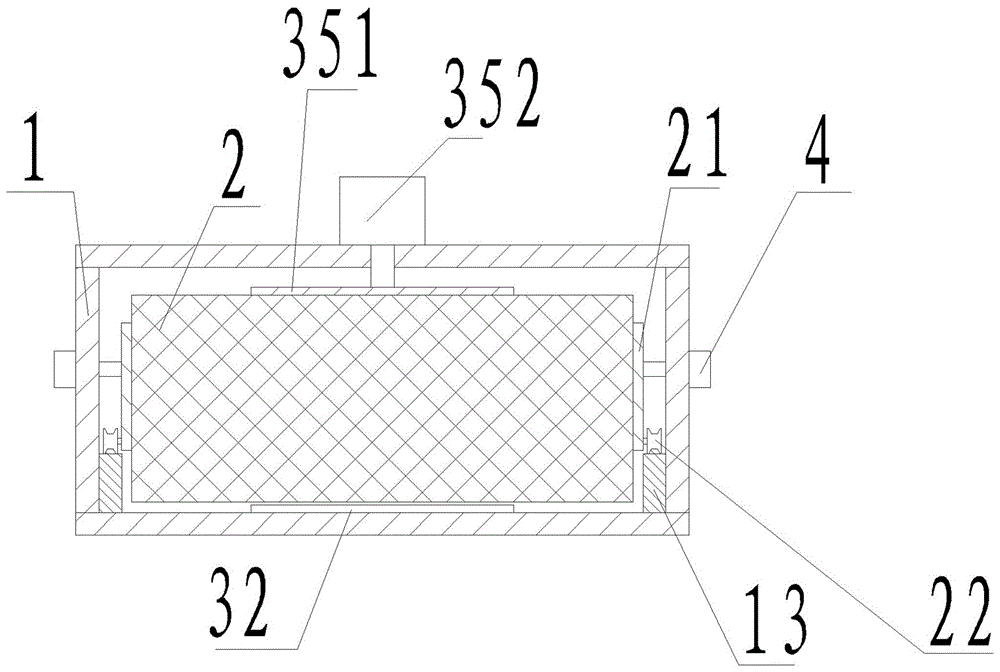

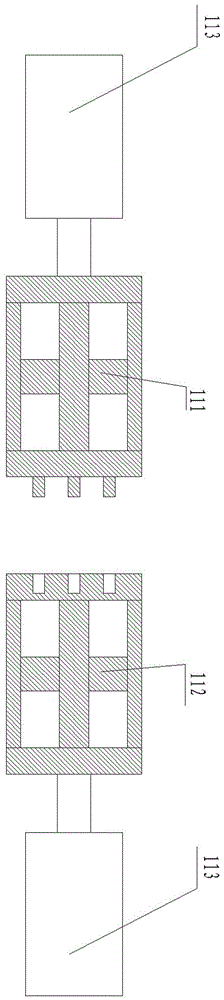

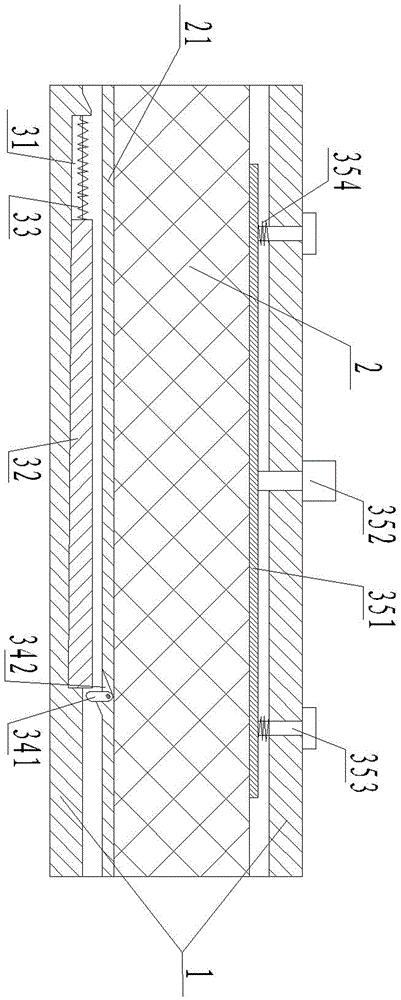

[0021] See attached Figure 1-4 , a chassis for pure electric vehicles, including a chassis frame supporting the weight of the vehicle body and a wheel assembly, a drive mechanism, a steering assembly, a brake assembly and a bumper arranged on the chassis frame, and the chassis frame includes The warehouse-type longitudinal beam 1 on the central axis of the chassis. The warehouse-type longitudinal beam 1 has a through structure, and the front and rear ends are respectively provided with a front sealing door 11 and a rear sealing door 12. Inside the warehouse-type longitudinal beam 1, the longitudinal guide mechanism The battery box 2 is installed and positioned with the positioning mechanism, and the emergency braking device for the battery box 2 is formed by means of the wedge-shaped brake shoe structure arranged at the bottom of the warehouse-type longitudinal beam 1 .

[0022] See attached figure 2 , 4 , the wedge-shaped brake shoe structure includes a wedge-shaped groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com