Automatic express package packaging machine and packaging method thereof

A technology of automatic packaging machine and packaging method, which is applied in the direction of packaging and article rotation wrapping, etc., which can solve the problems of large space occupation, high manufacturing cost of fully automatic packaging manipulators, and the inability of small and medium-sized express companies to purchase, etc., to achieve a small footprint , Good practical value, cheap manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention are described below in conjunction with the drawings as follows:

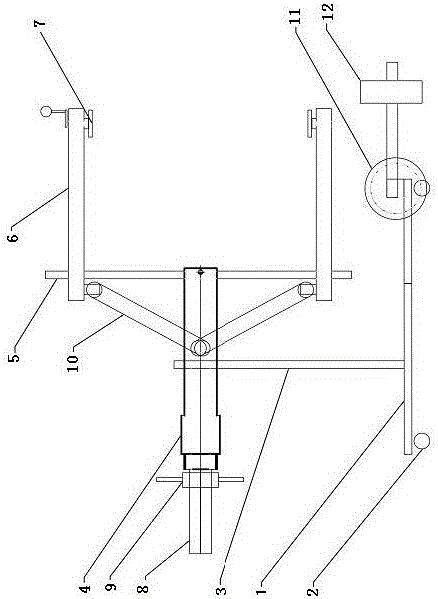

[0011] in figure 1 Among them, this kind of express package automatic packaging machine includes a base 1, four pulleys 2 under the base 1, a vertical plate 3 at one end of the base 1, and a rod sleeve 4 and a rod sleeve 4 horizontally installed on the upper part of the vertical plate 3 through a bearing. The front end and the center of the support rod 5 are connected by a pin hole. The two ends of the support rod 5 are movably inserted into the two holes of the splint 6. The front end of the splint 6 is equipped with an elastic clamp 7 through a bearing, and the rod sleeve 4 is installed through a thread There is a screw 8, the end of the screw 8 outside the rod sleeve 4 is sleeved with a nut 9. The front end of the screw 8 is connected to one end of two equal-length connecting rods 10 through a pin hole, and the other end of the connecting rod 10 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com