Staggered discharge device of medical parts

A technology for discharging devices and accessories, which is applied to conveyor objects, transportation and packaging, conveyors, etc., can solve problems such as inability to detect, and achieve the effects of improving reliability, increasing quantity, and speeding up labor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

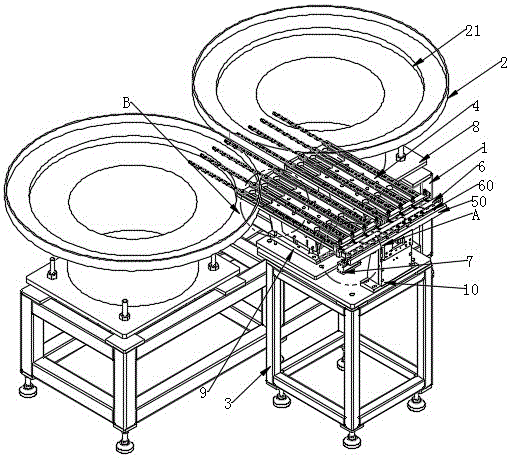

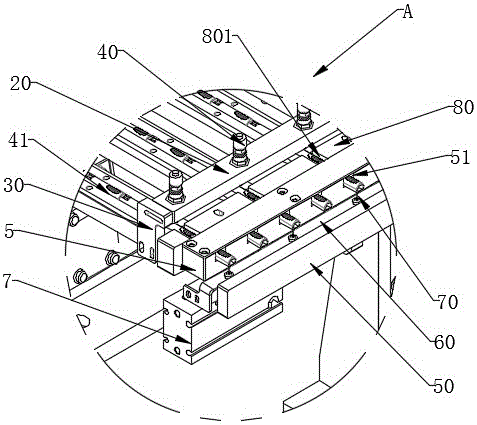

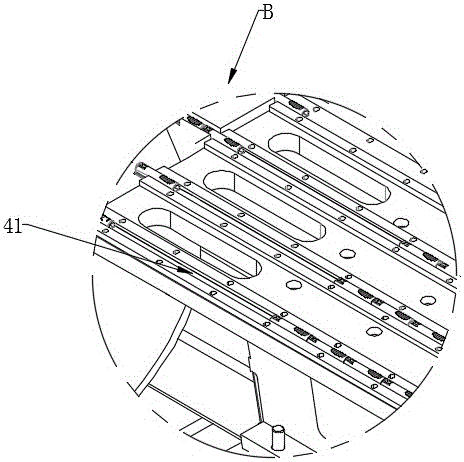

[0059] figure 1 It is a structural schematic diagram of an embodiment of a dislocation discharging device for medical accessories in the present invention; figure 2 for figure 1 Partial enlarged view of part A in middle; image 3 for figure 1 Partial enlarged view of part B in ; figure 1 , figure 2 as well as image 3 As shown, the dislocation discharge device for medical accessories provided in this embodiment is used as a delivery device for medical accessories for safety venous needles. The dislocation discharge device includes: a vibration unit, a flat delivery unit, a dislocation unit and an optical fiber detection unit .

[0060] In this embodiment, the position of the vibrating plate support 1 is defined as the rear of the dislocation discharge device; the position of the horizontal feeding support 3 is defined as the front of the dislocation discharge device.

[0061] Specifically, the horizontal delivery unit is located between the vibration unit and the disp...

Embodiment 2

[0087] Figure 20 It is a schematic structural diagram of Embodiment 2 of a dislocation discharge device for medical accessories; Figure 20 As shown, the dislocation discharge device also includes an adjustment unit, and the adjustment unit is connected with the dislocation unit to adjust the spatial position of the dislocation unit, so that the input port of the medical accessories on the dislocation unit is opposite to the output port of the medical accessories on the flat delivery unit together.

[0088] The dislocation feeding device provided in this embodiment pushes the dislocation movable plate 5 through the dislocation cylinder 7, so that the odd-numbered square grooves 51 and the even-numbered square grooves 51 on the dislocation movable plate 5 are respectively connected with the strips on the flat feeding base plate 4 in sequence. The rectangular groove 41 is connected to increase the quantity of accessories feeding, and at the same time, the optical fiber sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com