Sediment combined treatment process

A treatment process and bottom sludge technology, which is applied in the direction of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problems of landscaping and building sintering, low building use value, and large floor area. It achieves the effect of resource utilization, wide application, good filter press effect and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

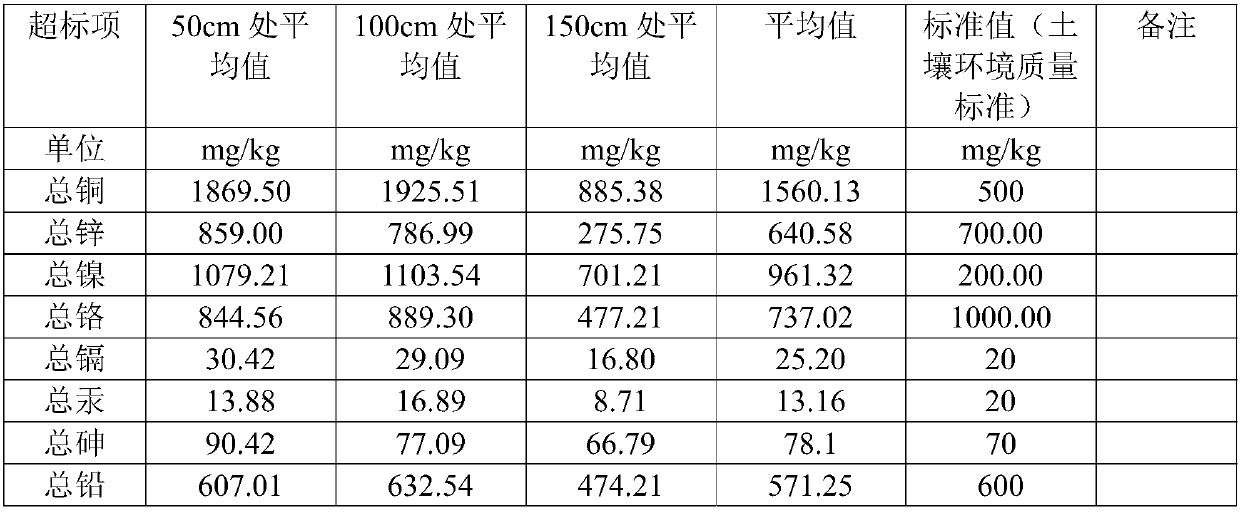

[0043] See Table 1 for the water quality components of the dredged sediment of a certain river.

[0044] Table 1 Detection indicators of heavy metals in sediment

[0045]

[0046] The treatment process is as follows:

[0047] 1) Filter out gravel, fibers and breccia above 2mm and above 0.5mm through the coarse and fine screens.

[0048] 2) Through the biochemical homogenization reaction tank, then inject 10ppm of biological oxidant into the biological homogenization reaction tank with a metering pump, and the aeration rate is 15m 3 / ㎡·h, the aeration time is 2.5h, to remove part of the organic matter in the sediment, to achieve the purpose of detoxification and deodorization, and at the same time, it is beneficial to the dehydration and drying of the sediment.

[0049] In this step, the biological oxidants used include bromelain, lysozyme, yeast fermentation product, protease inhibitors, xylitol and polyethylene glycol, wherein the mass fraction of bromelain is 55%, and t...

Embodiment 2

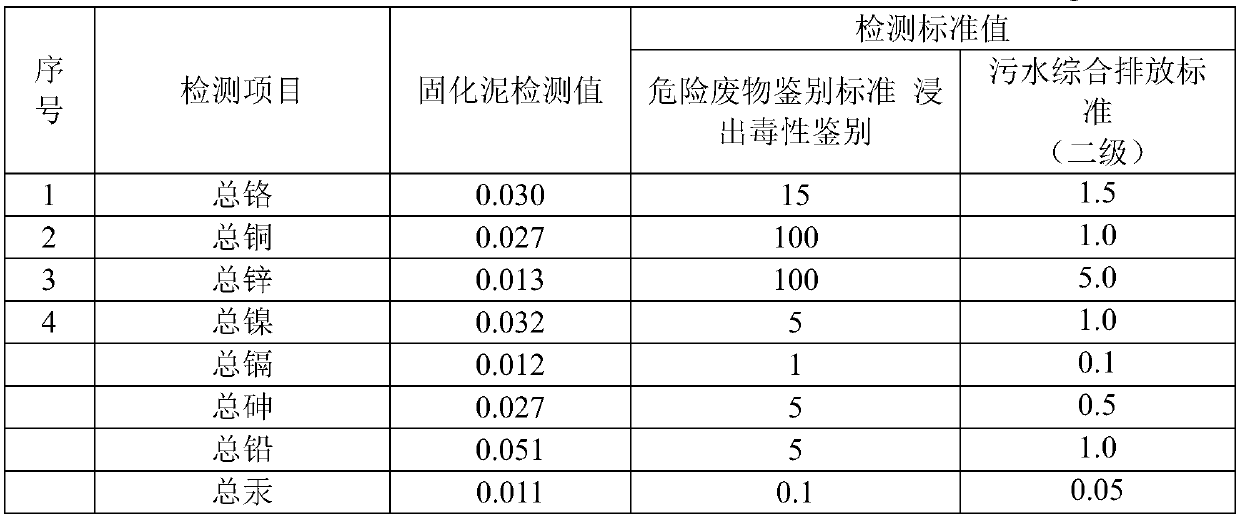

[0058] See Table 3 for the water quality composition of the dredged sediment of a certain river.

[0059] Table 3 Detection indicators of heavy metals in sediment

[0060]

[0061]

[0062] The treatment process is as follows:

[0063] 1) Filter out gravel, fibers and breccia above 2mm and above 0.5mm through the coarse and fine screens.

[0064] 2) Through the biochemical homogenization reaction tank, and then 15ppm biological oxidant, the aeration rate is 10m 3 / ㎡·h, the aeration time is 2.5 hours, to remove part of the organic matter in the sediment, to achieve the purpose of detoxification and deodorization, and at the same time, it is beneficial to the dehydration and drying of the sediment.

[0065] In this step, the biological oxidants used include bromelain, lysozyme, yeast fermentation product, protease inhibitors, xylitol and polyethylene glycol, wherein the mass fraction of bromelain is 55%, and the mass fraction of lysozyme is 6%. Protease inhibitors accou...

Embodiment 3

[0074] See Table 5 for the water quality composition of the dredged sediment of a certain river.

[0075] Table 5 Detection indicators of heavy metals in sediment

[0076]

[0077]

[0078] The treatment process is as follows:

[0079] 1) Filter out gravel, fibers and breccia above 2mm and above 0.5mm through the coarse and fine screens.

[0080] 2) Through the biochemical homogenization reaction tank, then inject 10ppm of biological oxidant into the biological homogenization reaction tank with a metering pump, and the aeration rate is 15m 3 / ㎡·h, the aeration time is 2.5h, to remove part of the organic matter in the sediment, to achieve the purpose of detoxification and deodorization, and at the same time, it is beneficial to the dehydration and drying of the sediment.

[0081] In this step, the biological oxidants used include bromelain, lysozyme, yeast fermentation product, protease inhibitors, xylitol and polyethylene glycol, wherein the mass fraction of bromelain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com