Lime digestion, mixing and dedusting process and equipment

The technology of a dust removal device and a mixing device is applied in chemical instruments and methods, dispersed particle separation, and the use of liquid separation agents, etc., and can solve the problems of dust and smoke pollution, low digestion efficiency of digesters, and poor digestion effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

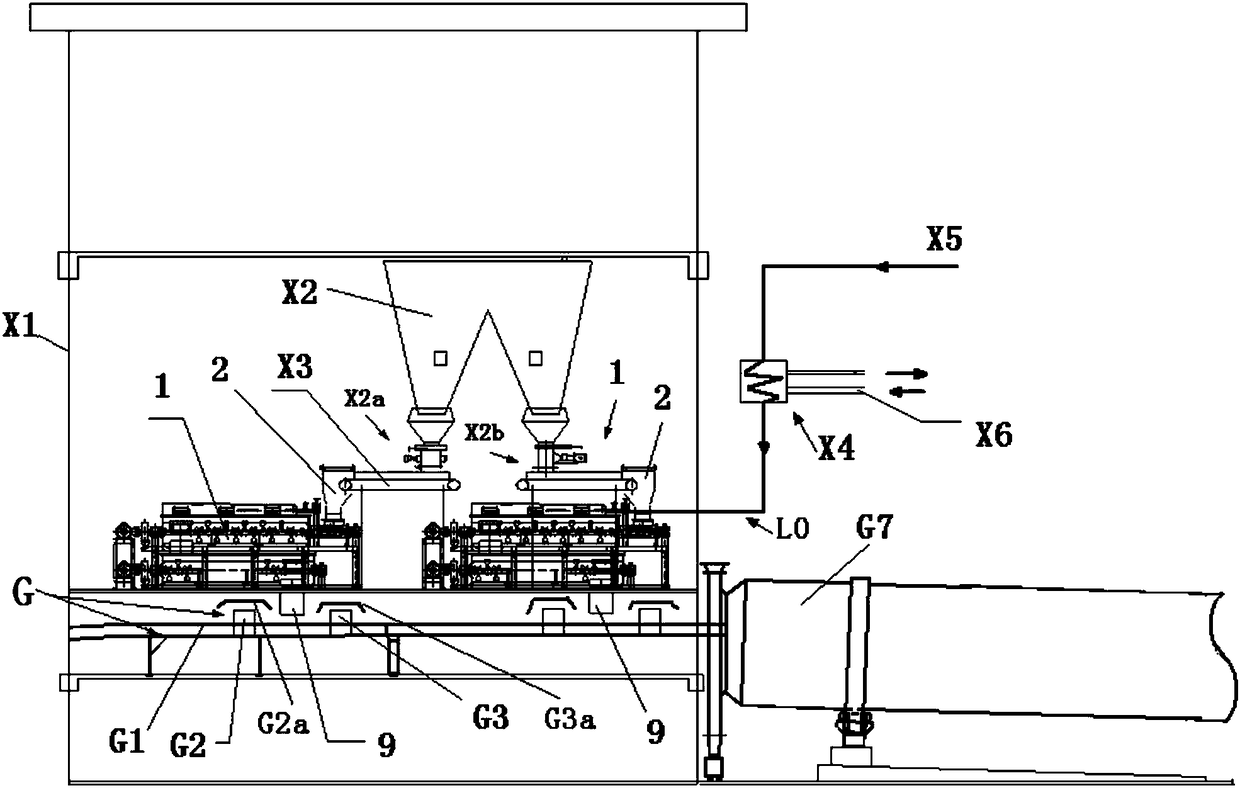

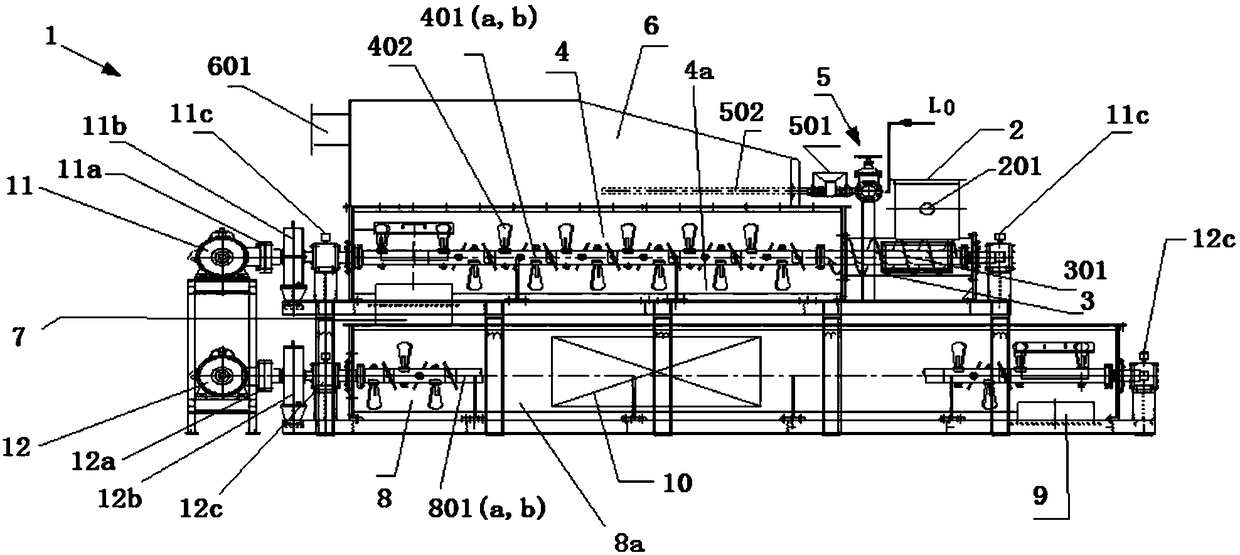

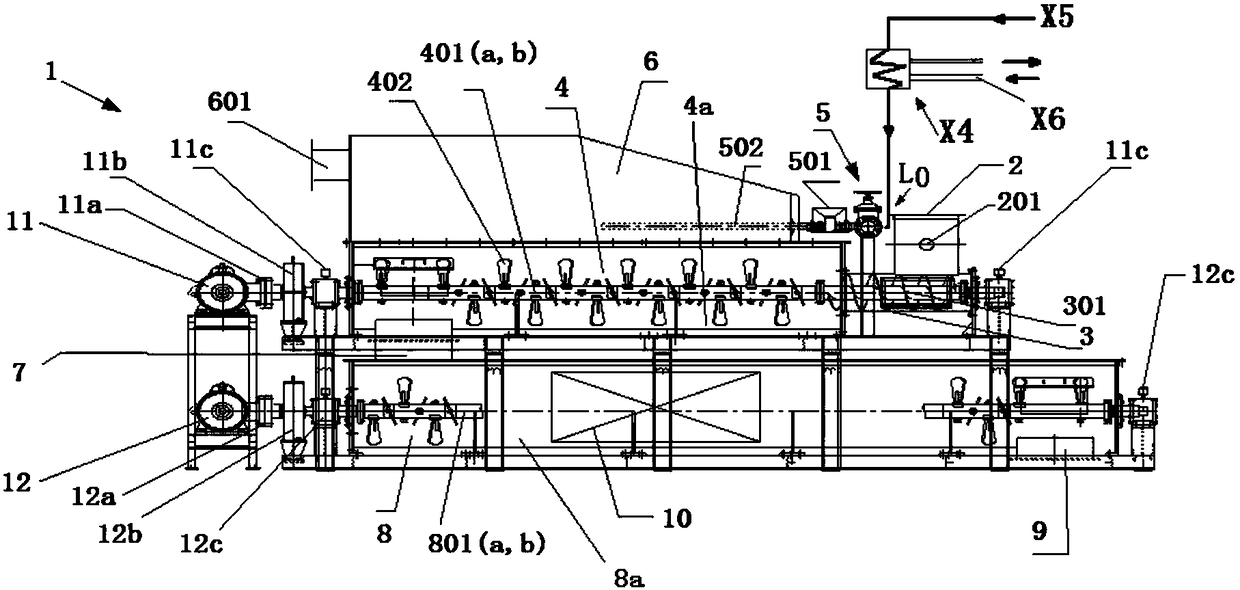

[0148] According to the first embodiment of the present invention, quicklime digestion and mixing equipment are provided, which includes: quicklime digester, belt conveyor belt mixing mechanism G and first mixing drum G7, wherein the belt conveyor belt mixing Material mechanism G includes belt conveyor belt G1, material pre-inspection and dust removal device G2 equipped with material separation device G201, material post-inspection and dust removal device G3 equipped with material aggregation device G301, belt conveyor roller G4 and G5, belt conveyor frame G6; wherein the digested quicklime outlet of the quicklime digester or the outlet of the digested quicklime output pipe is located above the conveyor belt G1 of the belt conveyor and is located between the material pre-inspection and dust removal device G2 and the material post-inspection and Between the dust removal device G3, wherein the discharge end of the belt conveyor belt G1 is located in the feeding section of the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com